Distillation kettle provided with automatic overflowing device

The technology of an overflow device and a distillation kettle is applied in the field of the distillation kettle, which can solve the problems of solvent waste, increase the burden of wastewater treatment, etc., and achieve the effects of saving production costs, reducing labor intensity, and improving distillation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

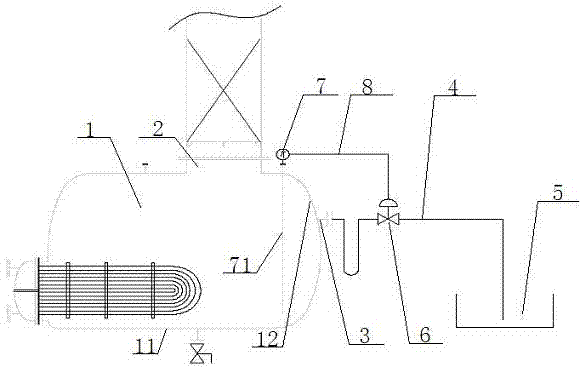

[0013] Such as figure 1 As shown, the present invention comprises still body 1, and still body 1 is provided with material feeding port 2, material overflow port 3, and material overflow port 3 is positioned at still body 1 rear head 12 places, and material overflow port 3. The overflow pipe 4 is connected to the collection box 5. The overflow pipe 4 is provided with a valve 6. The valve 6 is a temperature control valve. The still body 1 is provided with a temperature measuring instrument 7. The temperature measuring instrument 7 passes through the data line 8 is connected to the valve 6, the end of the measuring rod 71 of the temperature measuring instrument 7 is close to the bottom wall 11 of the internal cavity of the still body 1, and the pipeline between the valve 6 and the material overflow port 3 is in a "U" shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com