Liubao tea production process and equipment

A production process and technology for Liubao tea, applied in the field of Liubao tea production technology and equipment, can solve the problems of backward control level of automatic assembly line, low degree of automation, high labor intensity, etc. High, the effect of avoiding accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

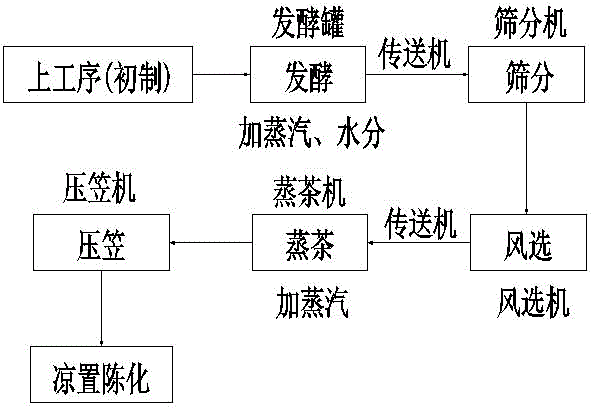

[0045] see figure 2 As shown, the steps of making Liubao tea using the Liubao tea production process and equipment are as follows:

[0046] (1) Fermentation: Put the primary Liubao tea into the fermenter 1, the temperature in the fermenter 1 is controlled at 55°C, the water content of the tea leaves is controlled at 26%, and the fermentation time is 7 days.

[0047] (2) Sieving: Feed the fermented tea leaves into the sieving machine, and the tea leaves will be sieved in multiple stages by the sieving machine to deblock and remove impurities from the agglomerated tea leaves during fermentation.

[0048] (3) Air selection: The tea leaves that have been sieved are sent to the air selection machine, and the tea leaves are further deblocked, impurity-removed, and dust-removed through the wind-selection machine.

[0049] (4) Tea steaming: The tea leaves selected by wind are sent into the tea steaming machine. The temperature of the tea steaming machine is controlled at 120°C, the ...

Embodiment 2

[0053] (1) Fermentation: Put the primary Liubao tea into the fermenter 1, the temperature in the fermenter 1 is controlled at 60°C, the moisture content of the tea leaves is controlled at 26%, and the fermentation time is 10 days.

[0054] (2) Sieving: Feed the fermented tea leaves into the sieving machine, and the tea leaves will be sieved in multiple stages by the sieving machine to deblock and remove impurities from the agglomerated tea leaves during fermentation.

[0055] (3) Air selection: The tea leaves that have been sieved are sent to the air selection machine, and the tea leaves are further deblocked, impurity-removed, and dust-removed through the wind-selection machine.

[0056] (4) Tea steaming: The tea leaves selected by wind are sent into the tea steaming machine, the temperature of the tea steaming machine is controlled at 130°C, the moisture content of the tea leaves is controlled at 17%, and the tea steaming time is 4 minutes.

[0057] (5) Pressing Li: Put the ...

Embodiment 3

[0060] (1) Fermentation: put the primary Liubao tea into the fermenter 1, the temperature in the fermenter 1 is controlled at 58°C, the moisture content of the tea leaves is controlled at 26%, and the fermentation time is 12 days.

[0061] (2) Sieving: Feed the fermented tea leaves into the sieving machine, and the tea leaves will be sieved in multiple stages by the sieving machine to deblock and remove impurities from the agglomerated tea leaves during fermentation.

[0062] (3) Air selection: The tea leaves that have been sieved are sent to the air selection machine, and the tea leaves are further deblocked, impurity-removed, and dust-removed through the wind-selection machine.

[0063] (4) Tea steaming: The tea leaves selected by wind are sent to the tea steaming machine. The temperature of the tea steaming machine is controlled at 125°C, the moisture content of the tea leaves is controlled at 18%, and the tea steaming time is 5 minutes.

[0064] (5) Pressing Li: Put the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com