Lightning arrester device capable of being dismounted and installed in charged state

A technology for lightning arresters and live parts, which is applied in the field of electrified detachable lightning arrester devices, and can solve the problems of high labor intensity and low work efficiency for maintenance workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

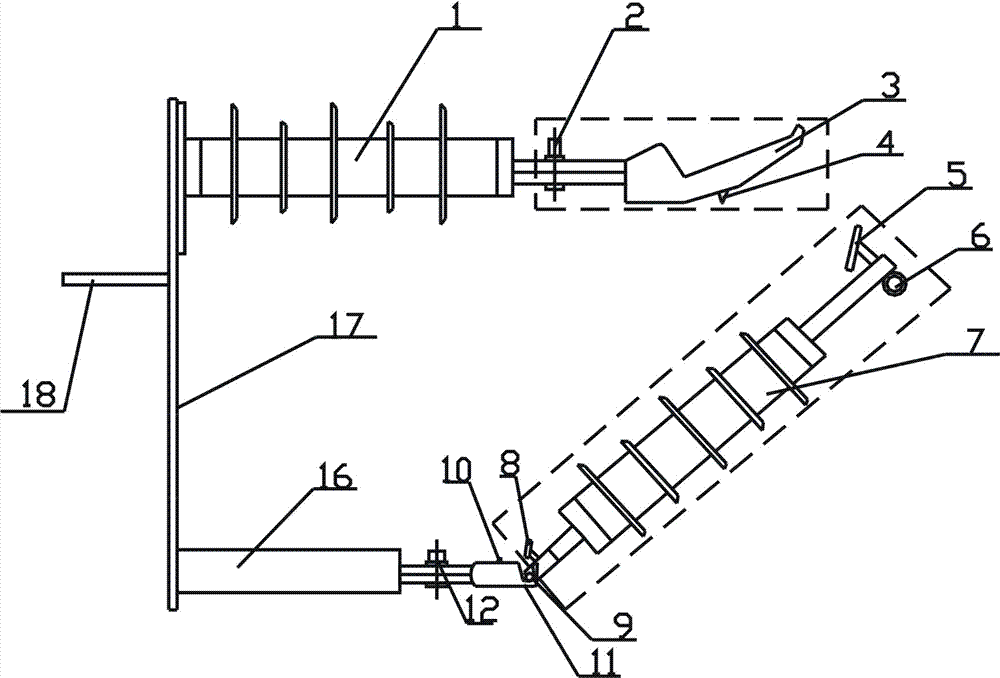

[0015] Embodiment 1 When the "chargeable detachable lightning arrester device" is running on the power grid, it needs to be removed, and at this time the power line cannot be powered off. The staff stands on the ground and uses a qualified insulating operating rod. The movable cover 3 of the charged end is bumped upwards, and the wedge 22 in the movable cover causes the movable contact 5 to separate from the static contact 4 due to displacement, and the removable assembly falls. The detachable assembly that falls this moment hangs in the rotating shaft bracket groove 11, and now the operator passes in the operating ring 6 with 24 forks at the top of the operating rod again, and the assembly is taken off.

Embodiment 2

[0016] Example 2 After replacing the qualified lightning arrester on the detachable assembly, use the 24 forks on the top of the operating rod to penetrate into the operation ring 6, and put the rotating shaft 9 of the detachable assembly into the rotating bracket of the grounding end 13 After entering the groove 11, forcefully bump the movable contact 5 of the detachable assembly into the movable cover 3 at the end of the charged component, so that the movable contact 5 enters the cover and the wedge 22 is stuck—the elastic force of the spring 19 on the movable cover 3 effect. At this time, the static contact 4 of the electrified assembly is in close contact with the movable contact 5, and the movable contact 9 at the lower end of the detachable assembly also rotates and moves forward to closely contact with the static contact 10 to conduct. Complete the operation of installing the lightning arrester when it is live.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com