Spiral material taking machine for biomass power generation

A biomass power generation and reclaimer technology, applied in the directions of loading/unloading, transportation and packaging, packaging, etc., can solve problems such as many accidental failures, the screw reclaimer cannot be well adapted, and the fuel adaptability is poor, so as to avoid Accidental failure, convenient and efficient transportation, good transportation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

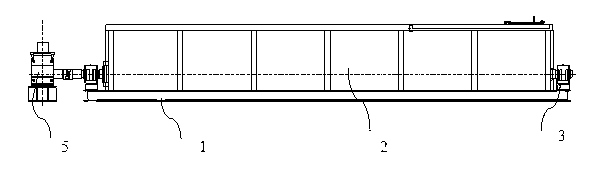

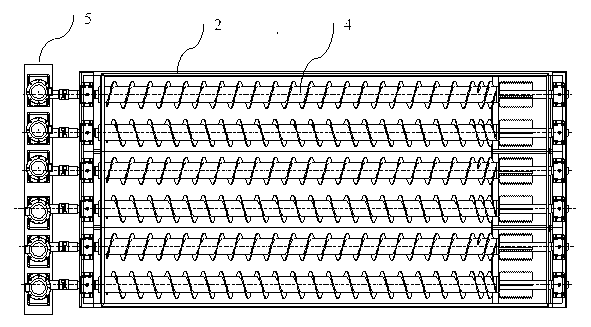

[0012] like figure 1 and figure 2 As shown, the screw reclaimer for biomass power generation includes a base 1, a housing 3, a screw assembly 3 and a hydraulic system 5, wherein the screw assembly 3 is installed on the base 1, and the screw assembly 3 is arranged inside the housing 2 The screw assembly 3 is composed of six screw shafts 4 arranged side by side, and the screw blades of adjacent screw shafts 4 have opposite helical directions; the hydraulic system 5 includes a gear reducer, a hydraulic motor and a pressure switch used in conjunction. The hydraulic system 5 is arranged on the same side of the screw shaft 4 in one-to-one correspondence with the screw shaft 4 .

[0013] Working process: When the biomass fuel in the silo is accumulated to a certain height, the material is conveyed and taken out by the screw shaft 4 at the bottom, and contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com