Telescopic truss structure for field operation

A telescopic and truss technology, applied in the field of agricultural equipment, can solve problems such as damage to the beam and folding joints of the boom, complicated folding control mechanism, and difficult control of the balance of the boom, so as to facilitate storage and transportation, improve the utilization rate of agricultural resources, Lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

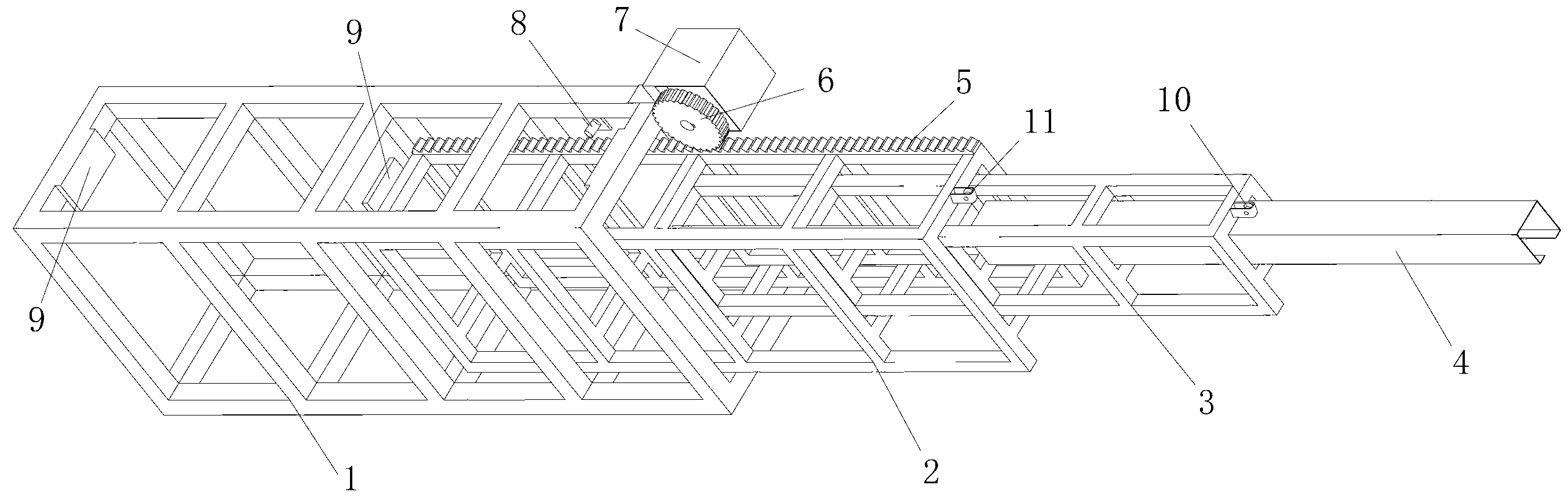

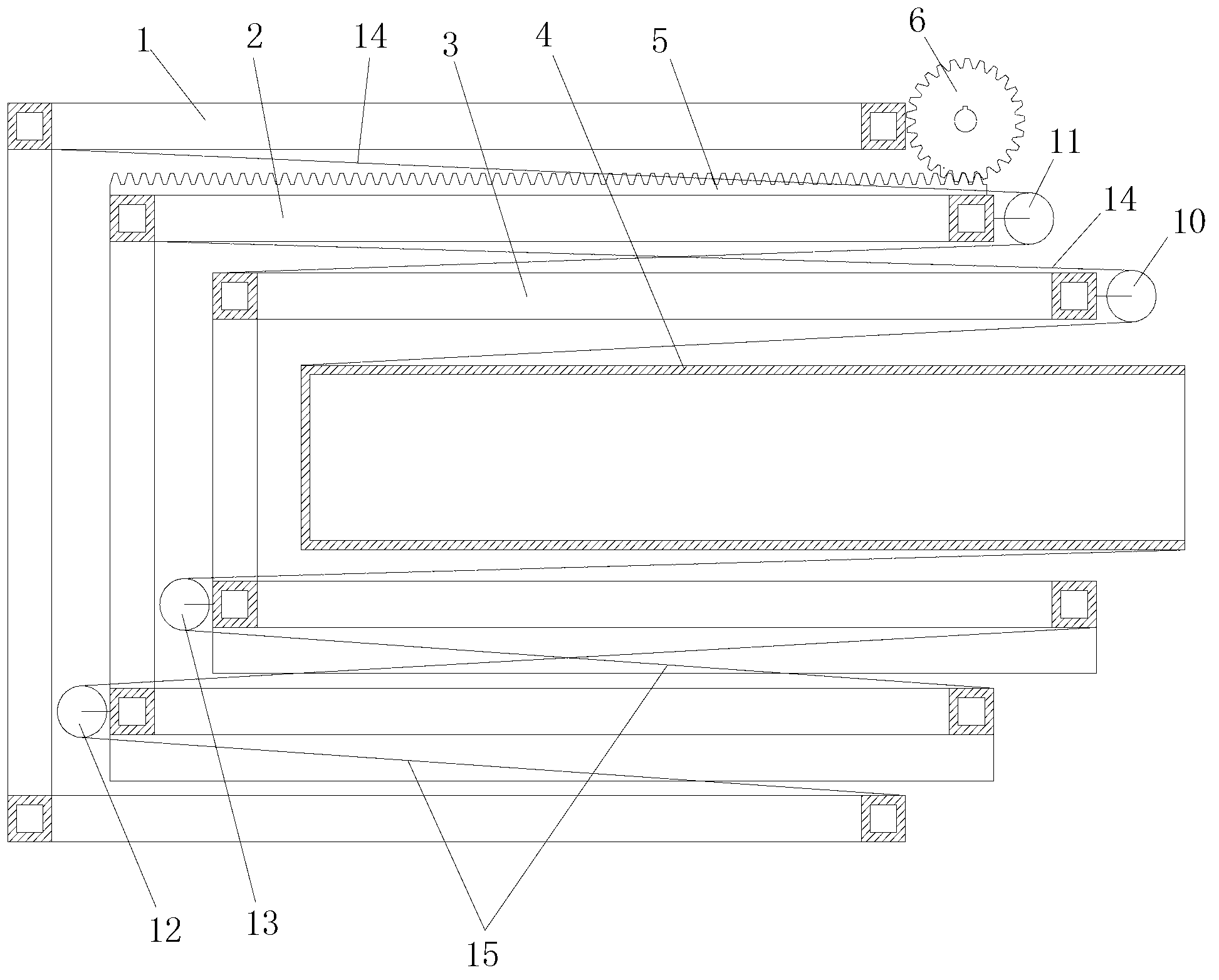

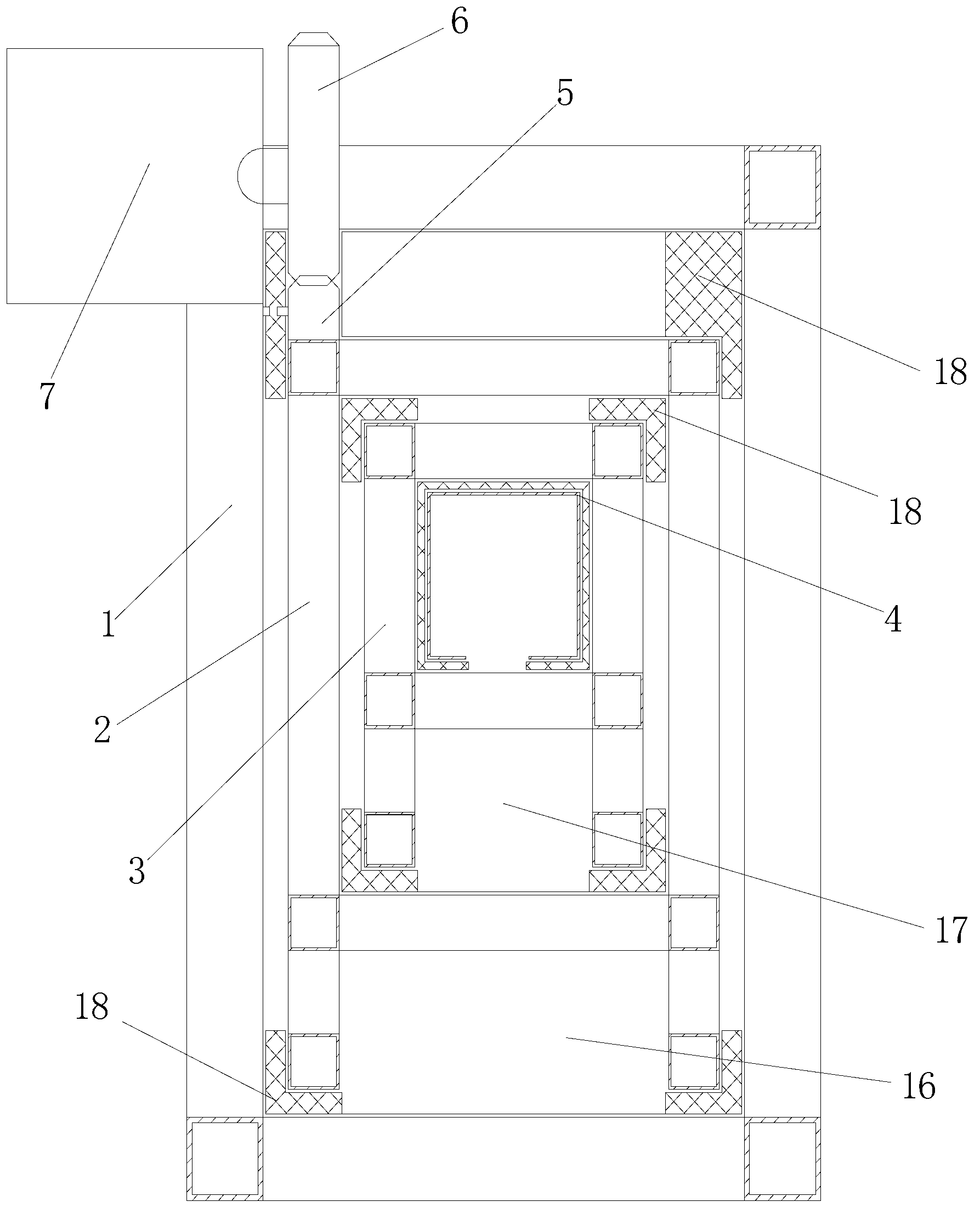

[0030] Such as Figure 1 to Figure 3 The shown telescopic truss mechanism for farmland operations is characterized in that it includes a power device, a transmission mechanism, and a plurality of trusses that slide and socket sequentially from outside to inside, wherein the truss located at the outermost layer is the first stage Truss 1, the second-level truss is the second-level truss 2;

[0031]The power device is installed on the first-level truss 1, and the power device is connected to the second-level truss 2 through a transmission mechanism; except for the first-level truss 1 and the innermost truss, the outer ends of the other layers of trusses are all provided with There are extended pulleys, and the inner ends are equipped with retractable pulleys; the extended pulleys are equipped with extended steel wire ropes 14, and the two ends of the extended steel ropes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com