A microseismic monitoring system and its installation method

A microseismic monitoring and microseismic sensor technology, which is applied in the direction of measuring devices, seismology, geophysical measurement, etc., can solve the problems of cumbersome operation, manpower consumption, and affecting the sensing accuracy and sensitivity of microseismic sensors, so as to achieve good sensing accuracy and sensitivity , The effect of facilitating construction and layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

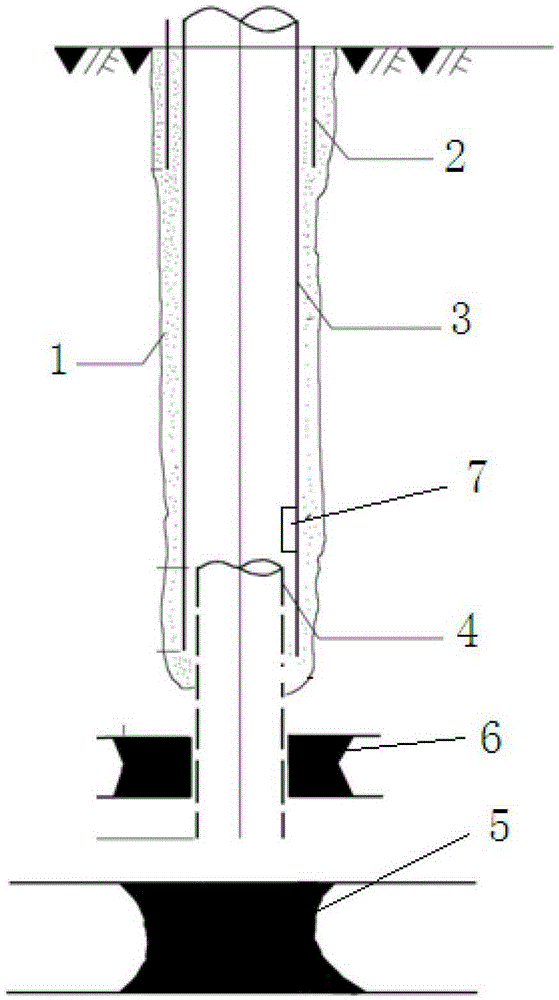

[0036] Such as figure 1As shown, the surface pre-drainage hole includes a cementing 1, a surface casing 2 is arranged at the position of the cementing 1 opening on the ground, a technical casing 3 is sleeved in the surface casing 2, and a technical casing 3 The lower part is set with a gas production casing 4; the gas production casing 4 passes through the upper adjacent layer 5 to reach a position near the top of the coal seam 6; the microseismic sensor 7 is installed on the inner wall of the technical casing 3 and is close to the gas production casing 4 position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com