Wet clutch

A wet clutch, clutch technology, applied in clutches, friction clutches, fluid-driven clutches, etc., can solve problems such as unfavorable weight and inertia moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

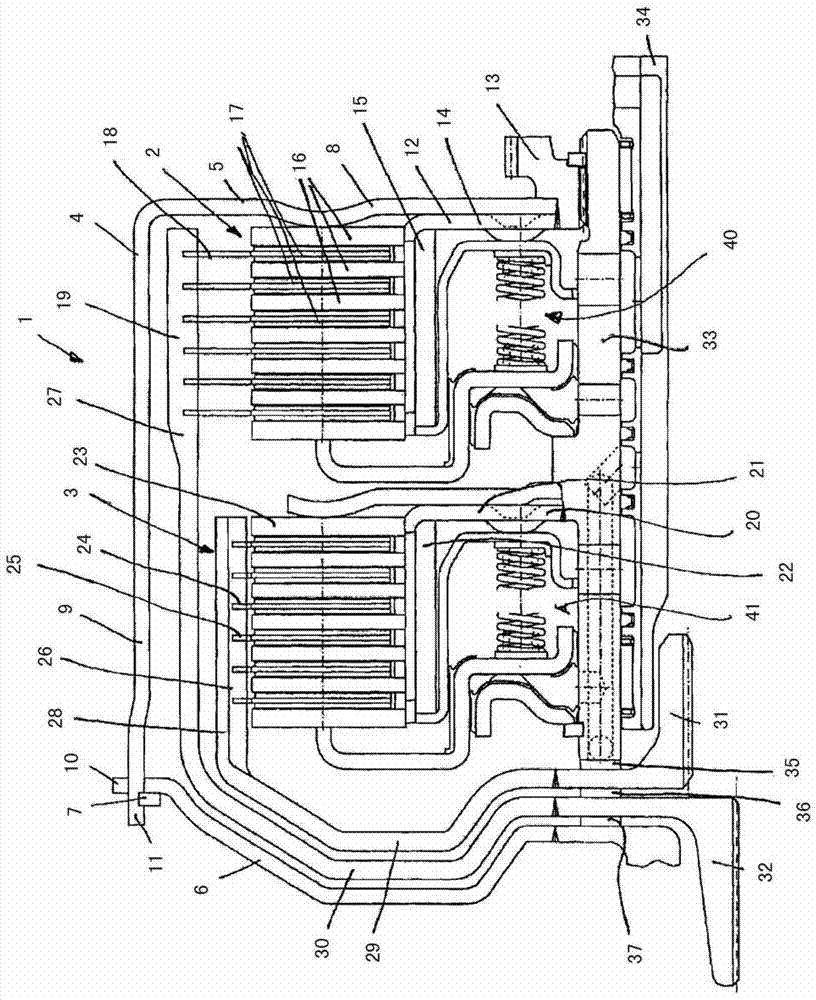

[0023] figure 1 A wet clutch 1 is shown, which can also be referred to as a double clutch or double wet clutch, wherein the wet clutch 1 is only shown in half section. The wet clutch 1 here comprises a first partial clutch 2 and a second partial clutch 3 . The first partial clutch 2 and the second partial clutch 3 are arranged side by side as viewed in the axial direction, wherein the radial extent of the first partial clutch is approximately the same as that of the second partial clutch. Slight differences can be seen in the area of the outer sheet carrier, but the sheets are approximately the same with respect to their radial extension.

[0024] The first partial clutch 2 and the second partial clutch are here substantially surrounded by a clutch housing 4, wherein the clutch housing 4 comprises a clutch pot 5 and a clutch cover 6 which are non-rotatable and They are connected to each other in a torque-transmitting manner and axially fixed and secured to each other in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com