Method and device for producing chlorobenzyl chloride through continuous rectification

A rectification technology of o-chlorobenzyl chloride, applied in the field of rectification, can solve problems such as low production efficiency, low labor efficiency, and unstable product quality, and achieve the effects of stable product quality, reduced labor intensity, and continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

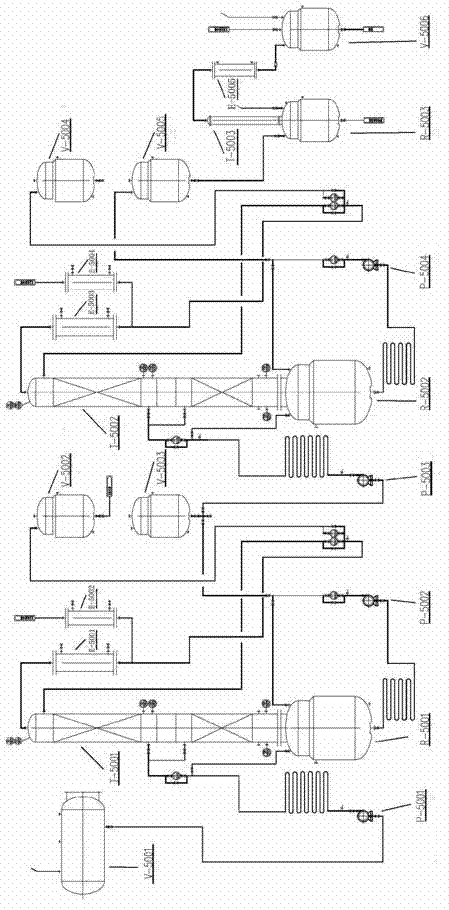

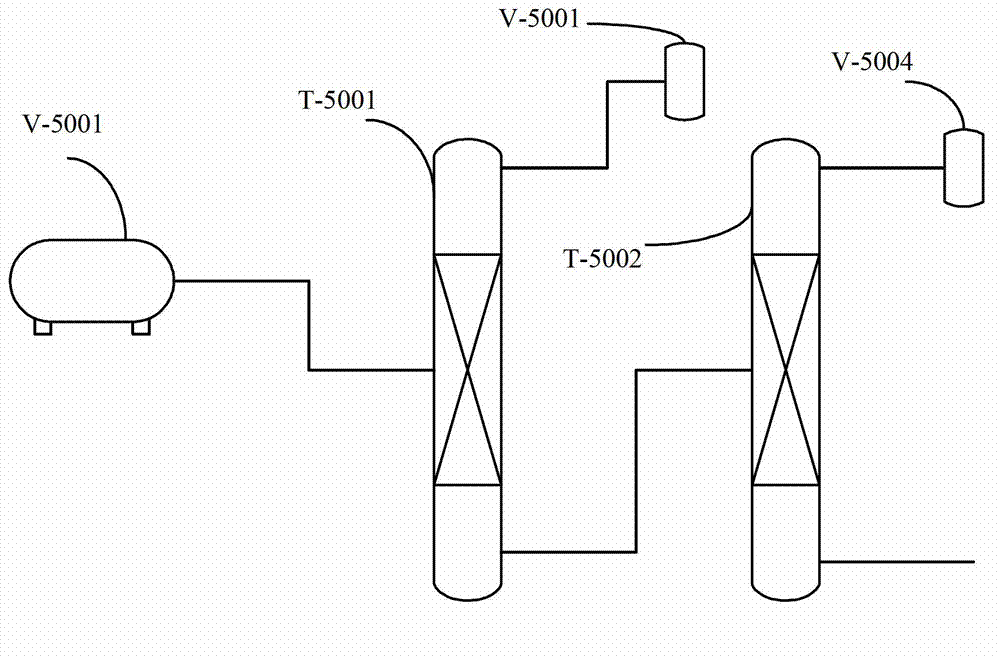

[0022] device such as figure 1 with figure 2 As shown, the chlorinated liquid is first connected to the feed port in the middle of the first rectified tower T-5001 from the middle tank V-5001 of the chlorinated liquid through the feed pump P-5001 of the first rectified tower, and the first rectified tower T- At the bottom of 5001, the first rectification tower reactor R-5001 is connected to the second rectification tower raw material tank V-5002 through the first rectification tower tower discharge pump P-5002, and then through the second rectification tower feed pump P-5002 is connected to the feed port in the middle of the second rectification tower T-5002, and the top of the first rectification tower T-5001 passes through the main condenser of the first rectification tower through E-5001 and the tail condenser of the first rectification tower E-5002 is connected to the front fraction receiving tank V-5002, and the second rectifying column tower tank R-5002 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com