Transmitter with preassembled synchronizing rings

A technology of transmitter and synchronizing ring, applied in the direction of intermeshing clutches, clutches, mechanical drive clutches, etc., can solve the problems of complex parts and huge structures, and achieve the effect of simple structure and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

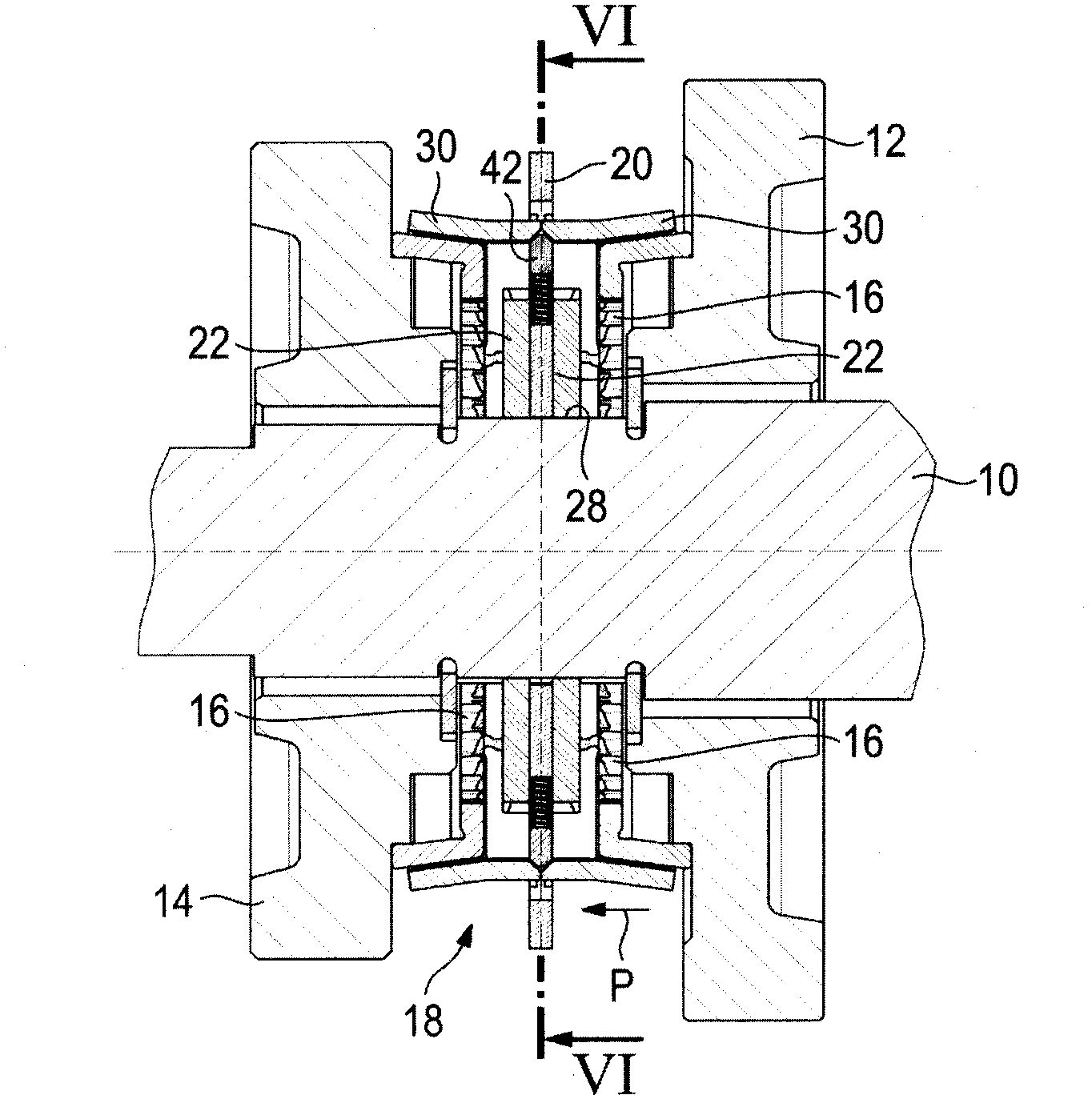

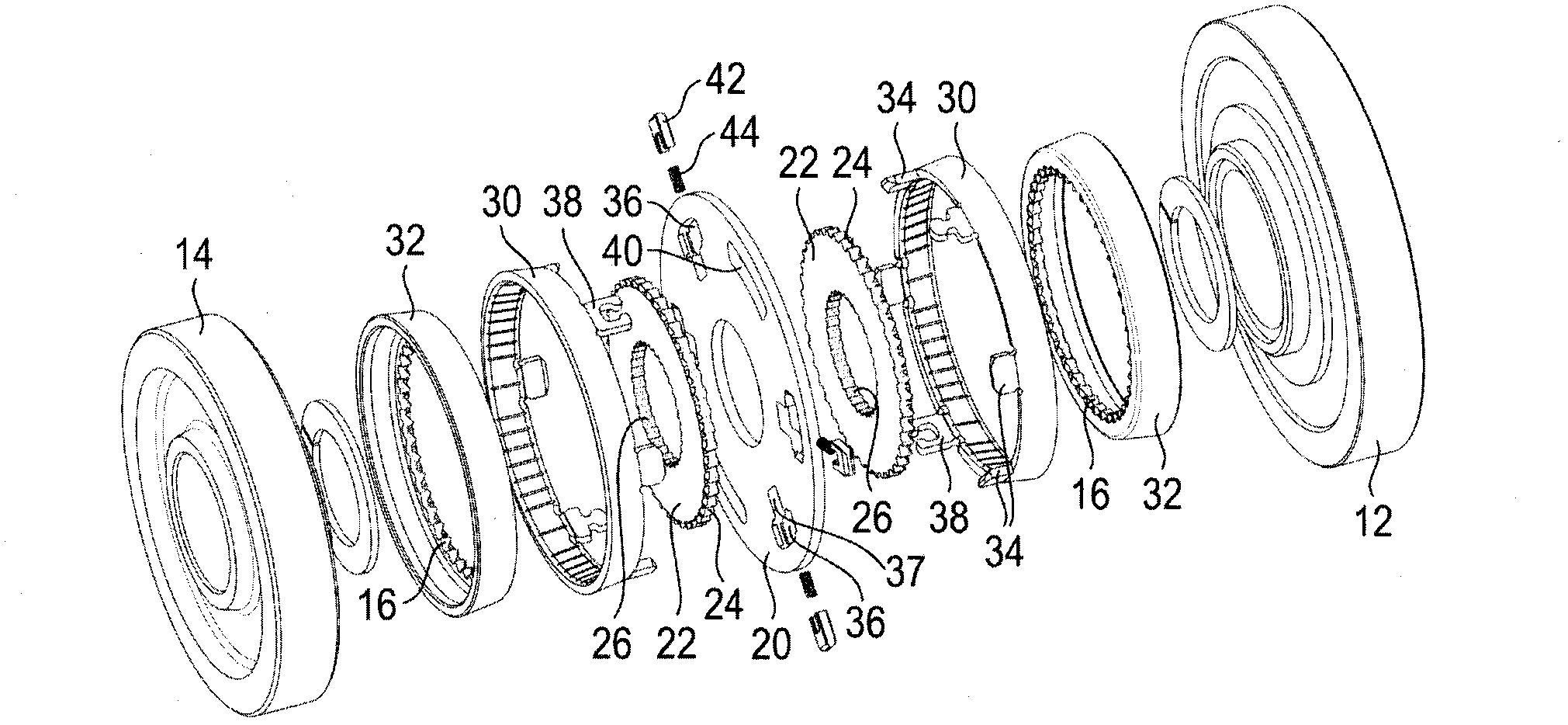

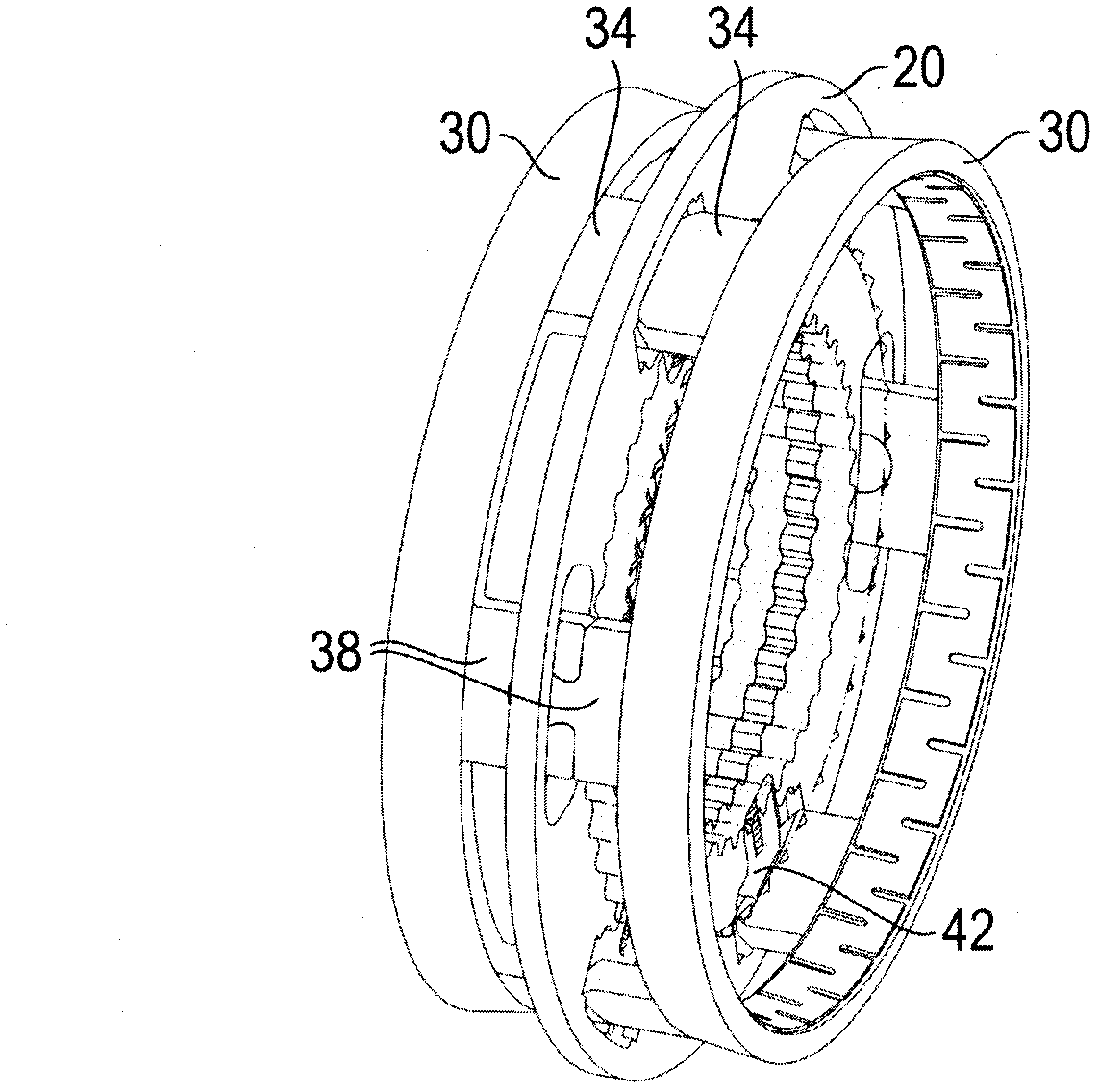

[0056] The following will refer to Figure 1 to Figure 8 The basic structure of a synchronization assembly for a manual transmission in which the transmitter according to the first embodiment is used is described.

[0057] The transmission comprises a gear shaft 10 on which two transmission gears 12, 14 are arranged. The two speed change gears 12, 14 are in the form of movable gears, ie they can rotate relative to the gear shaft. Clutch teeth 16 are connected to each speed change gear 12, 14 for common rotation therewith.

[0058] A transmitter 18 is arranged between the two transmission gears 12 , 14 , here the transmitter 18 is formed by a transmitter disk 20 and two clutch disks 22 . Two clutch disks 22 are arranged on either side of the transmitter disk 20 and have external toothing 24 and internal toothing 26 . The outer teeth 24 are made complementary to the clutch teeth 16 and the inner teeth 26 mesh with the pinion shaft teeth 28 . Accordingly, the clutch disc 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com