Full-automatic upsetting straight thread twister

A fully-automated, twisting machine technology, applied to thread cutting tools, thread cutting machines, metal processing machinery parts, etc., can solve the problems of rib stripping comb knife broken teeth, cumbersome operation, high processing cost, etc., and achieve thread accuracy and consistency , Convenient and quick operation, high thread precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific drawings and embodiments.

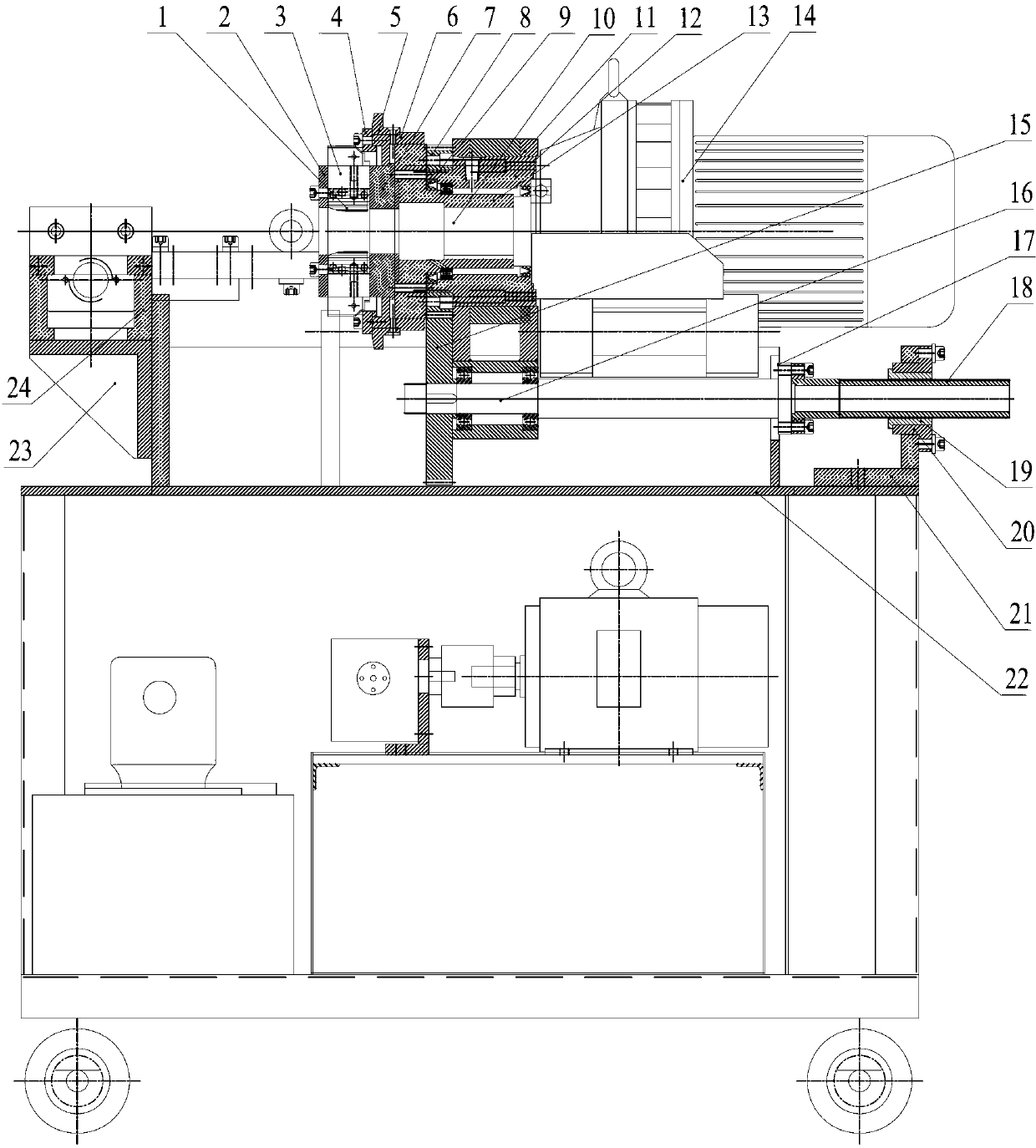

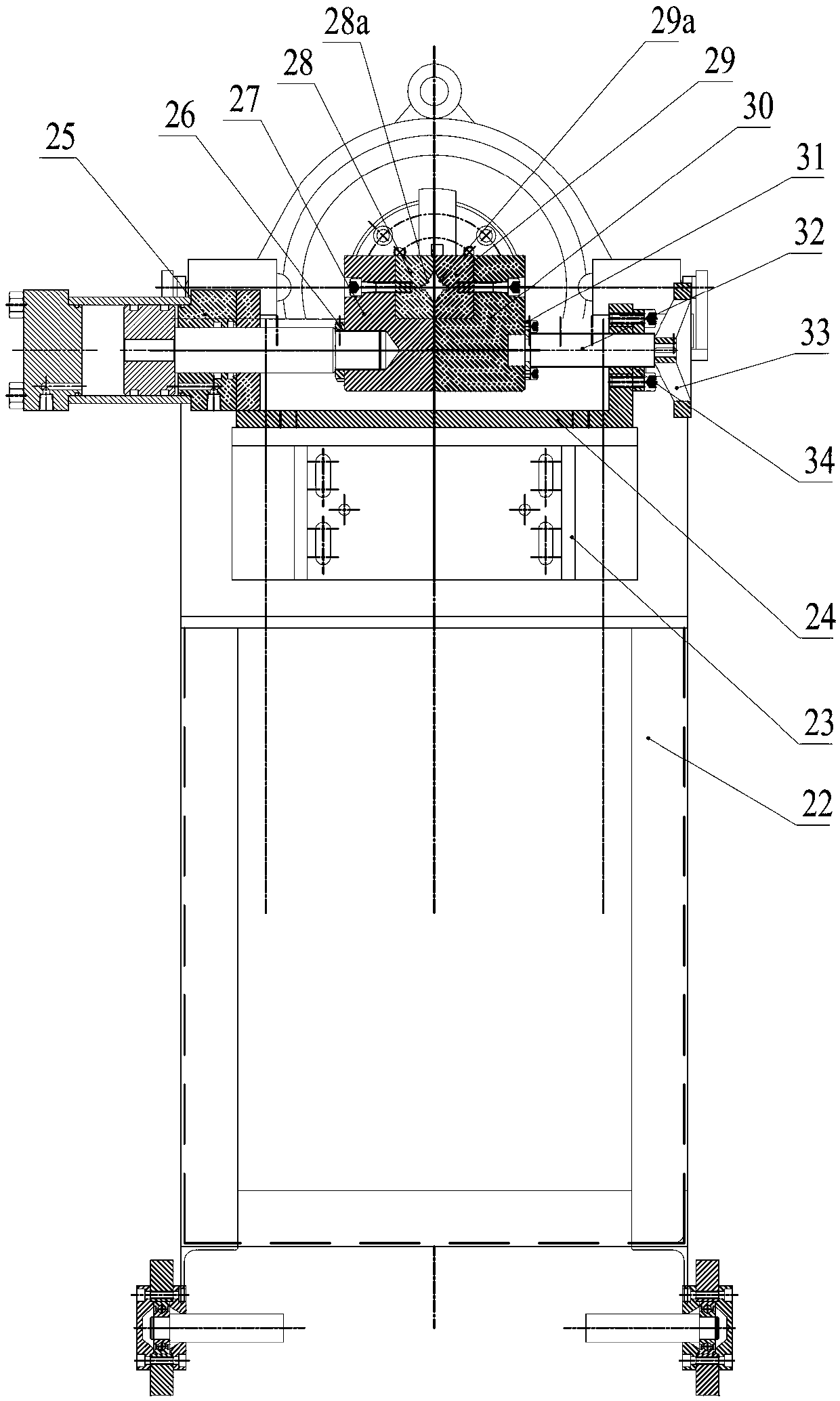

[0030] As shown in the figure: the fully automatic upsetting straight thread stranding machine in the embodiment mainly includes a steel bar clamping device and a rib peeling and twisting device installed on the frame 22, and the steel bar clamping device is installed at one end of the frame 22 , The steel bar clamping device is used to clamp and fix the steel bar so that the end of the steel bar is facing the rib stripping and twisting device; the rib stripping and twisting device is installed at the other end of the frame 22, and the rib stripping and twisting device is used to The steel ribs of the head are stripped and threaded.

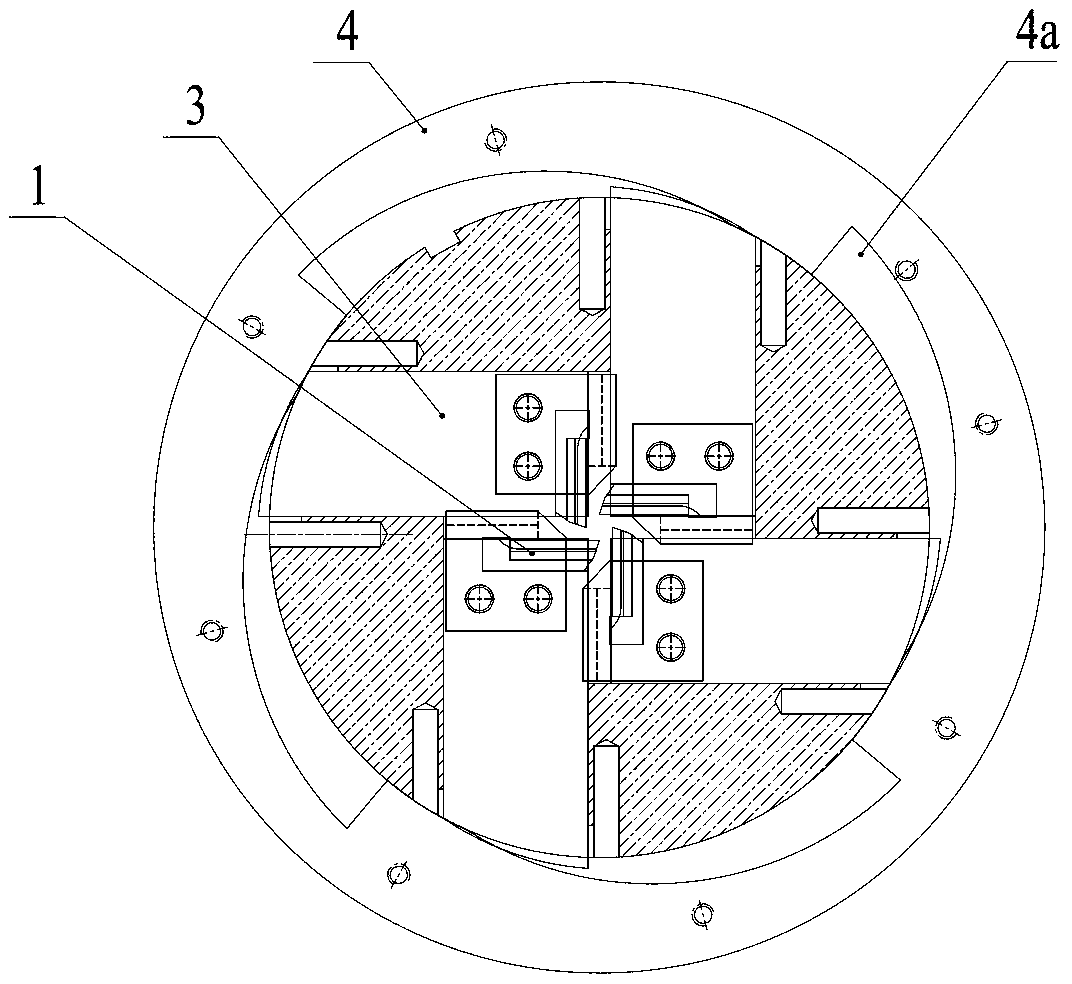

[0031] Such as figure 1 , figure 2 As shown, the rib stripping and twisting device mainly includes a rib stripping comb 1, a comb installation and adjustment mechanism, a transmission mechanism, and a speed reducer 14. The rib stripp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com