Low-oil-temperature instant noodles subjected to far infrared drying and preparation method thereof

A far-infrared drying and instant noodle technology, which is applied in the field of food processing, can solve the problems that instant noodles are prone to oil clam smell, oil is easy to deteriorate, and storage time is short, and achieve the effects of increasing noodle flavor, fast heating speed, and controlling oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: After cooking and cutting off the noodle block, put it in a noodle box, and dry it for the first time by far-infrared, with a power of 20 kW and a drying time of 20 minutes, to a moisture content of ≤15%; frying oil is heated to 30°C, According to the weight of the noodle block, the upper and lower sides are evenly sprayed with oil ≤ 15% at the same time; the noodle block is dried and shaped by the second far infrared, with a power of 20 kW and a drying time of 30 minutes.

Embodiment 2

[0038]Example 2: Noodles are cut off by steaming and placed in a frying box, and then dried by far-infrared for the first time, with a power of 20 kW and a drying time of 25 minutes, to a moisture content of ≤13%; the frying oil is heated to 60°C According to the weight of the noodle block, the upper and lower sides are evenly sprayed with oil ≤ 10% at the same time; the noodle block is dried and shaped by the second far infrared, with a power of 20 kW and a drying time of 30 minutes.

Embodiment 3

[0039] Example 3: Noodles are cut off by steaming and placed in a frying box, and dried by far infrared for the first time, with a power of 20 kW and a drying time of 30 minutes, to a moisture content of ≤10%; the frying oil is heated to 90°C According to the weight of the noodle block, the upper and lower sides are evenly sprayed with oil ≤ 5% at the same time; the noodle block is dried and shaped by the second far infrared, with a power of 20 kW and a drying time of 30 minutes.

[0040] Table 1: Indicators of finished instant noodles

[0041] instant noodles fried instant noodles Example 1 Example 2 Example 3 Oil content (%) 18.1 4.6 4.1 3.5 Moisture content (%) 4.2 7.0 6.6 6.5

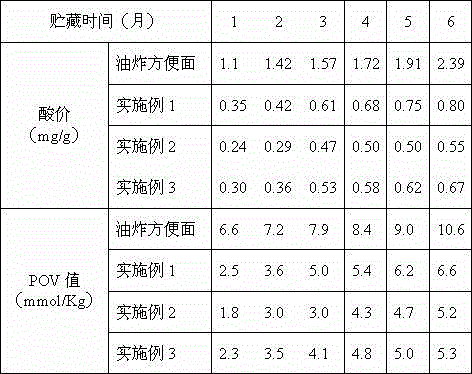

[0042] Table 2: Storage quality of instant noodles

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com