Resonant actuator using magnetic action for a power toothbrush

A technology for electric toothbrushes and actuators, applied in electric components, AC motor control, dentistry, etc., can solve the problems of increasing the mechanical stress of the spring, reducing the life of the appliance, and reducing the power output of the appliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

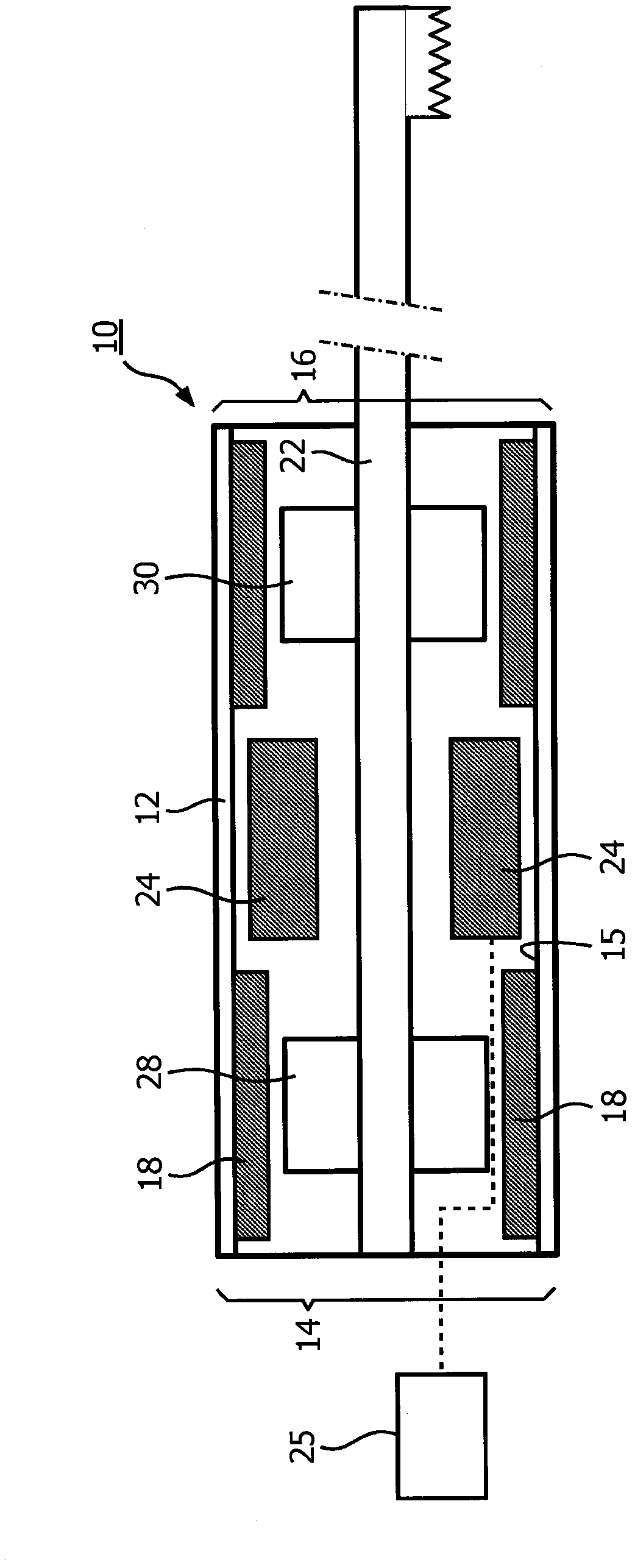

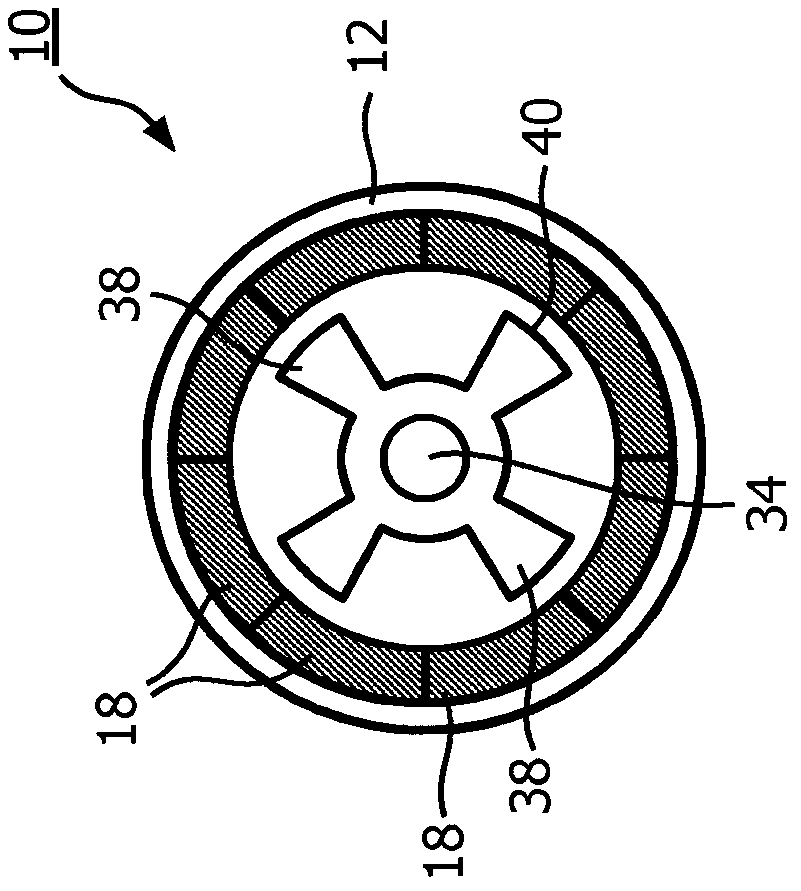

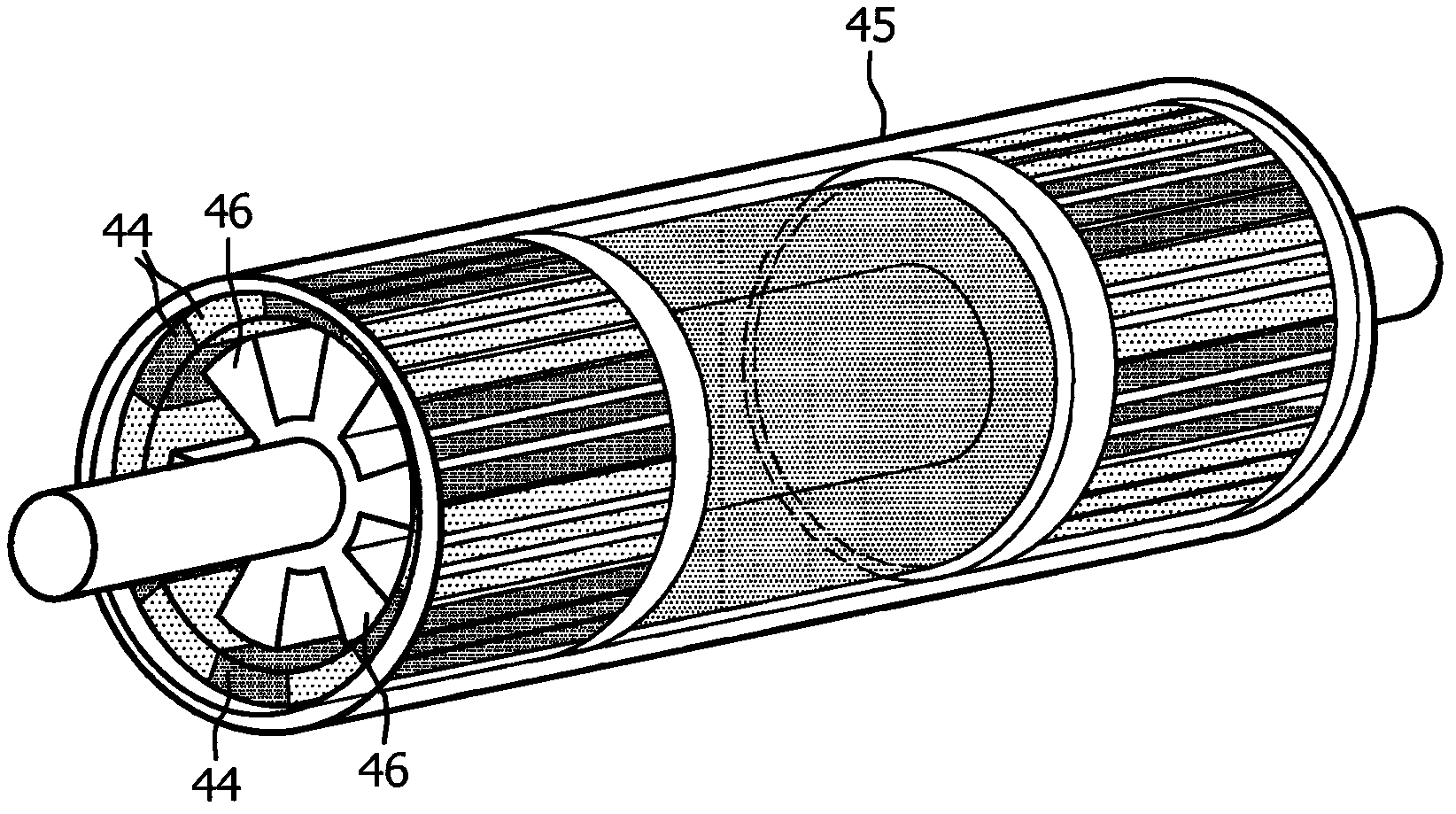

[0014] figure 1 with figure 2 A first embodiment of an actuator 10 is shown which may be used to drive a power toothbrush with a vibrating rotational motion through a selected angle. The actuator 10 includes an elongated cylindrical housing 12 preferably but not necessarily having a small (i.e., thin) diameter of about 12-15 mm, 13.6 mm in the illustrated embodiment. the preferred diameter. Such elongated actuator housings are commercially desirable, and the actuator structures described herein enable such elongated configurations.

[0015] In the illustrated embodiment are two permanent magnet assemblies 14 and 16 located within a housing 12 which is preferably made of a metal with high magnetic permeability since the housing is the magnetic circuit The two permanent magnet assemblies are located near opposite ends of the housing 12 and are attached to the inner surface 15 of the housing 12 . The permanent magnet assembly includes magnet parts 18-18 that alternate circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com