Buckle-type nut component

A snap-on, nut technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve problems such as thermal deformation, achieve convenient operation, good sealing effect, and ensure the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

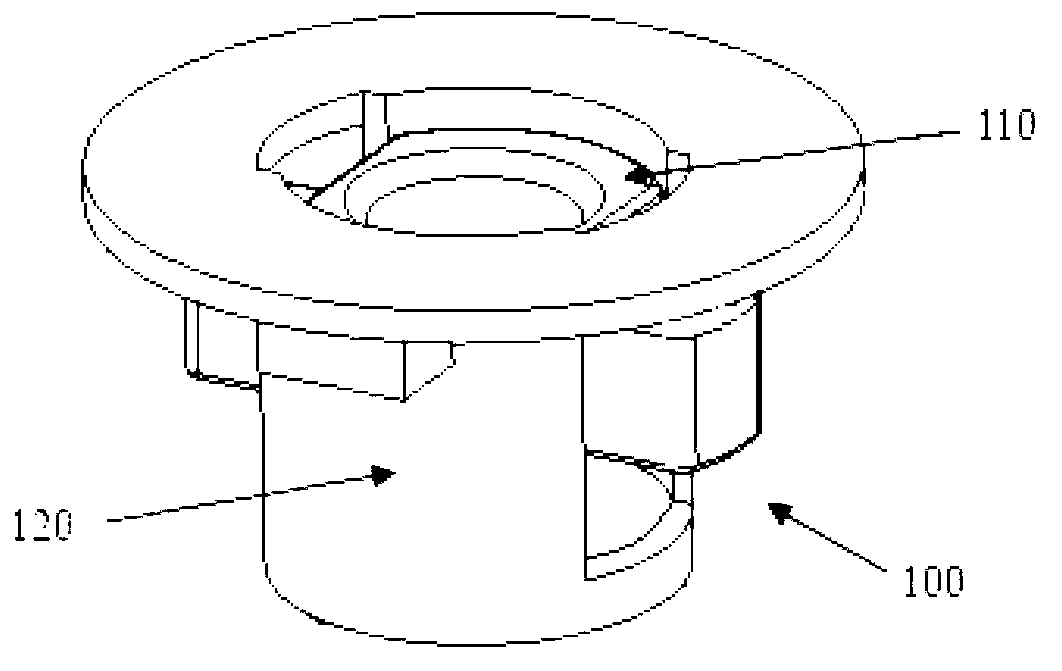

[0036] refer to figure 1 , the nut body 110 and the tubular member 120 are two separate components that are assembled together to form the nut assembly 100 .

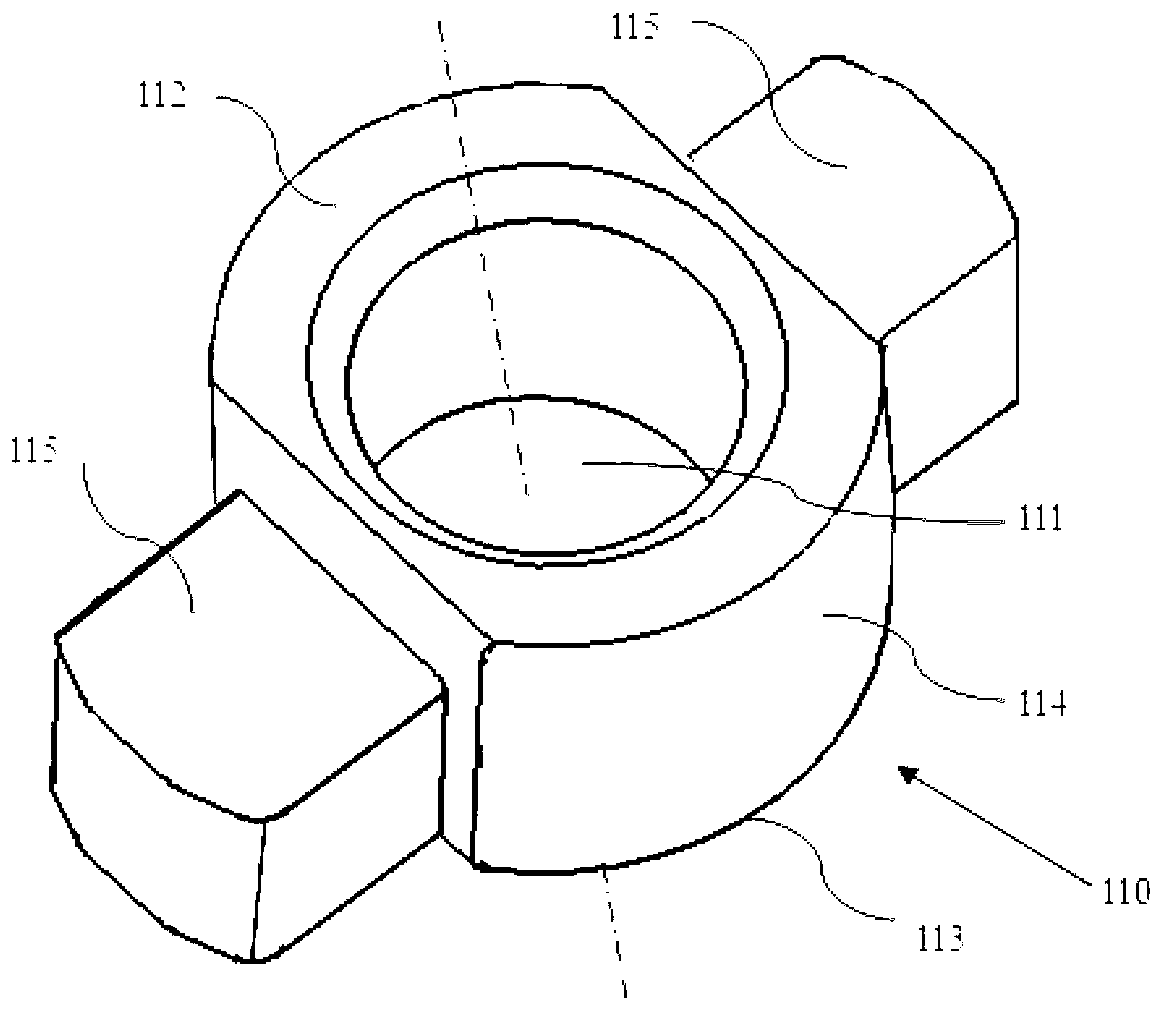

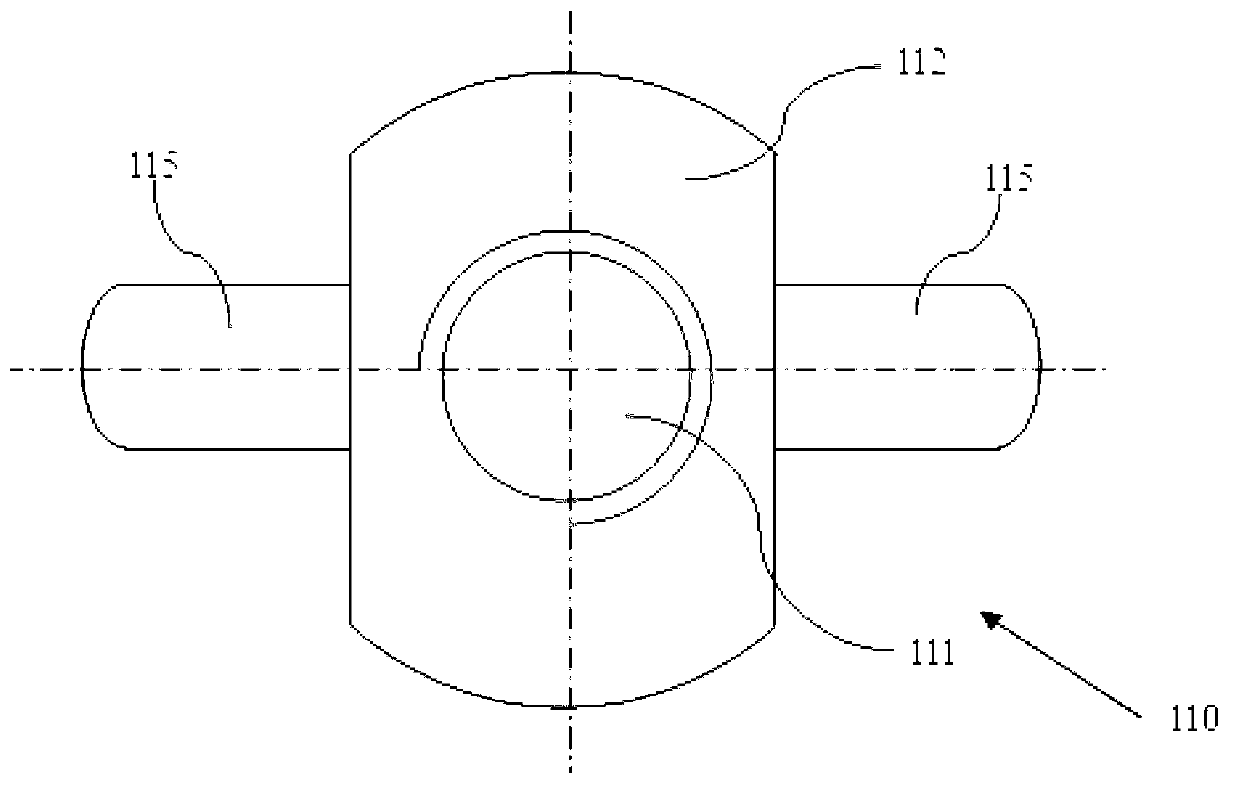

[0037] to combine figure 2 , image 3 and Figure 4 , which shows the specific structure of the nut body 110 in detail. Same as common nuts, the nut body 110 has a threaded hole 111 , an upper end surface 112 , a lower end surface 113 and a side wall 114 . Different from common nuts, there are two protruding wing-shaped portions 115 on the side wall 114 of the nut body 110 . The wing 115 also has an upper end face 1151 and a lower end face 1152 .

[0038] to combine Figure 5 , Image 6 and Figure 7 , which shows the specific structure of the tubular member 120 in detail. The tubular member 120 has two ends, one end is marked as 121 (ie, the upper end 121 in the figure), and the other end is marked as 122 (ie, the lower end 122 in the figure). The outer wall 123 of the tubular member 120 has flanges 126 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com