Method to produce concentrated cured kimchi fermentation liquor by using low-temperature evaporated chinese cabbage and radish concentrated liquor

A technology of kimchi fermented liquid and concentrated liquid, which is applied in food preparation, fruit and vegetable fresh-keeping, application, etc., can solve problems such as blanks, and achieve the effects of improving quality, reducing volume, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

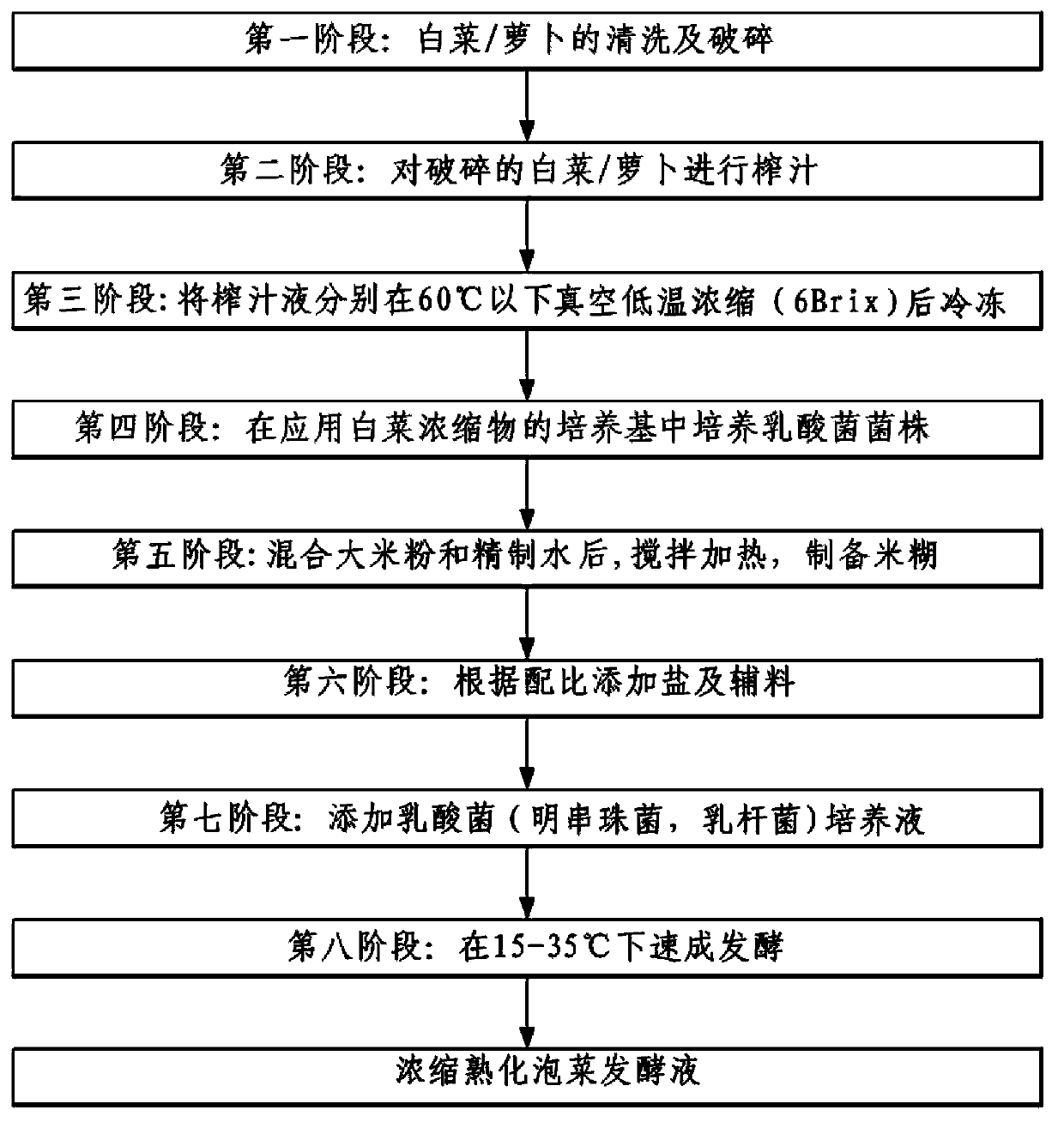

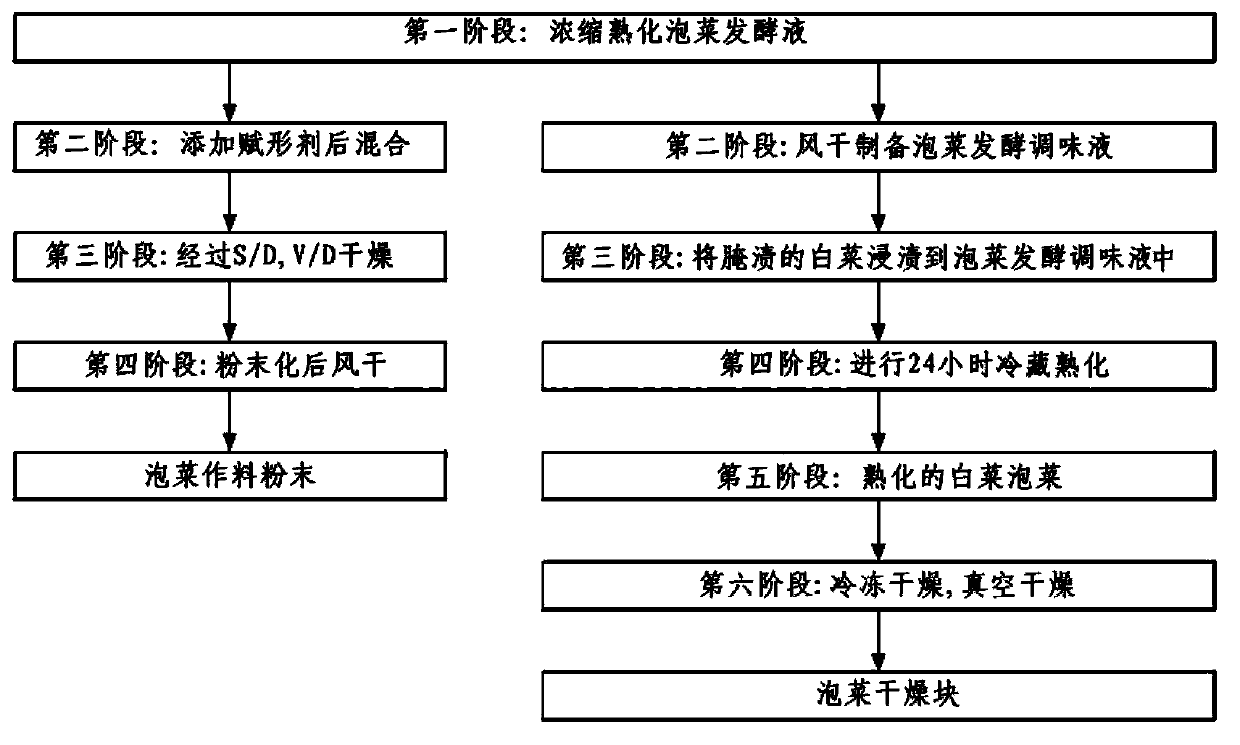

Method used

Image

Examples

Embodiment 1

[0041] The preparation of embodiment 1 cabbage and radish low temperature concentrate

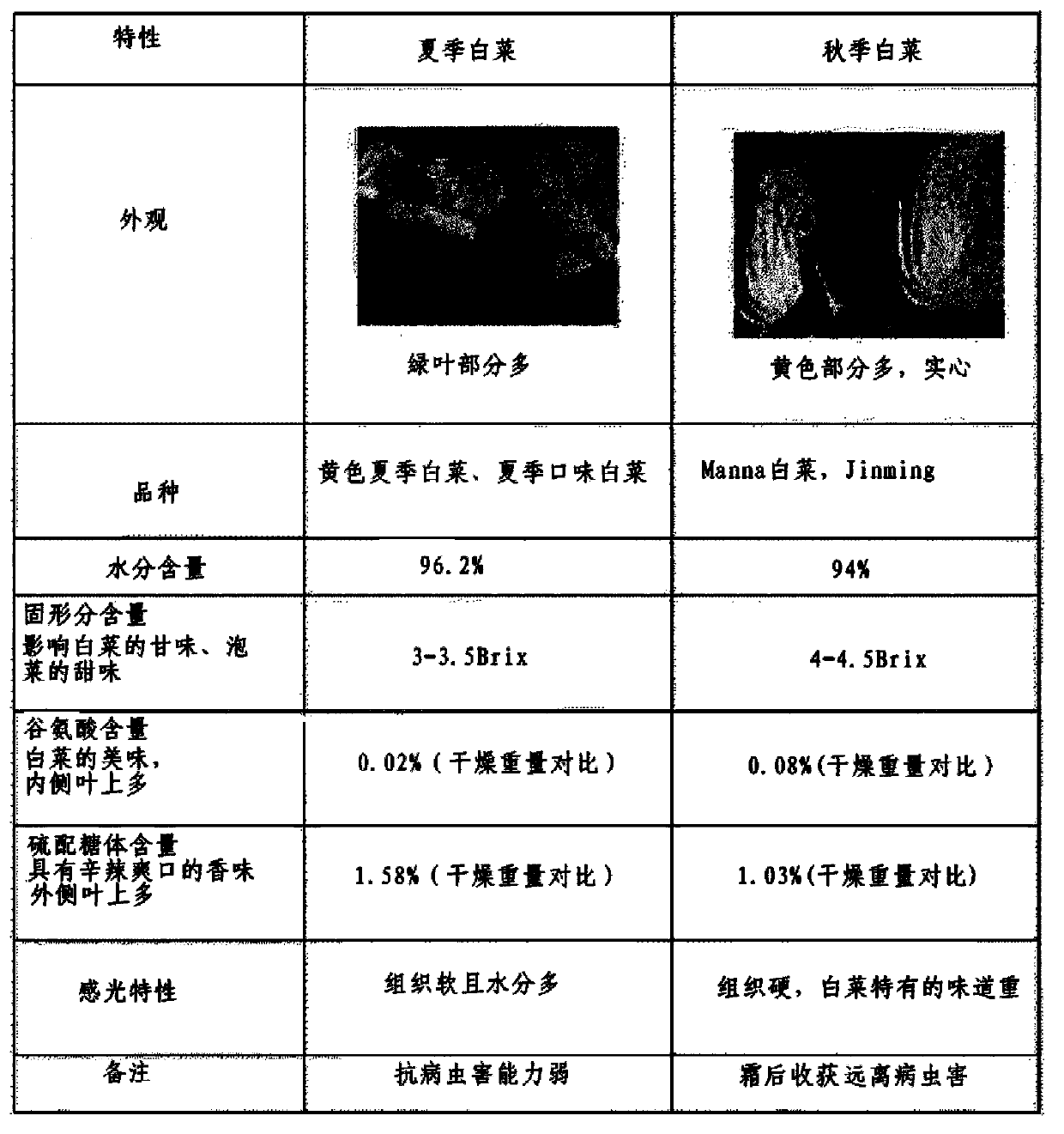

[0042] In the case of cabbage, which is the main raw material of kimchi, such as image 3 As shown, there were differences in quality characteristics between summer and autumn cabbage. In general, when considering the umami, sour, and pungent characteristics of kimchi, it is judged that cabbage in autumn is more suitable.

[0043] In the case of radish as an auxiliary ingredient of cabbage, such as Figure 4 As shown, there are differences in the quality characteristics of summer and autumn radishes. Autumn radishes contain a high amount of key ingredients that mainly express refreshing taste, so they are generally suitable for making kimchi.

[0044] But cabbage and radish are varieties with low storage and severe price fluctuations. Thus, the present invention washes and extracts juice after harvesting the raw materials during the Chinese cabbage and radish harvest period from October...

Embodiment 2

[0058] Embodiment 2 uses the lactic acid bacteria culture of Chinese cabbage concentrate

[0059] Prepare lactic acid bacteria culture solution, said lactic acid bacteria culture solution comprises 3~15% by weight of Chinese cabbage concentrate, 0.1~3.0% by weight of glucose, 0.1~0.3% by weight of yeast extract and 60~85% by weight of refined water, in the MRS The culture medium was inoculated with 0.1-5% of Leuconostoc enterococci, Lactobacillus plantarum, and Enterococcus faecium strains that were cultured once as lactic acid bacteria, and cultured at 28-32°C for more than 1 day.

[0060] Figure 6 It is a graph which investigated the pH of the lactic acid bacteria culture solution in the commercial MRS culture medium and the Chinese cabbage culture medium developed by this invention. Depend on Figure 6 It was found that the pH of the lactic acid bacteria culture solution decreased in the same pattern in both media. In Table 4 below, the number of lactic acid bacteria on...

Embodiment 3

[0065] Embodiment 3 Preparation of concentrated ripened kimchi fermented liquid according to the concentration of the concentrate

[0066] When the optimum ripening period of kimchi was regarded as pH 4.0±0.2, the time and pH of the concentrated ripened kimchi fermentation broth with different concentrations to reach the optimum ripening period were evaluated. Concentrated ripened kimchi fermented liquids using 10Brix and 20Brix concentrates were evaluated, and the evaluation results are shown in Table 5 below.

[0067] Table 5 Analysis of the properties of the mature kimchi fermentation broth according to the concentration of the concentrate

[0068]

[0069] As can be seen from the above Table 5, in the case of the 10Brix concentrate, it took 24 hours to complete the fermentation, and in the case of the 20Brix concentrate, it took 3 days to complete the fermentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com