The trim cover of the airbag installed on the steering wheel of the car

An airbag and steering wheel technology, applied in vehicle safety arrangement, pedestrian/occupant safety arrangement, vehicle parts, etc., can solve the problems of trim cover injection molding sink marks, narrow tear line width, affecting the appearance quality of trim cover surface, etc. Easy to open effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

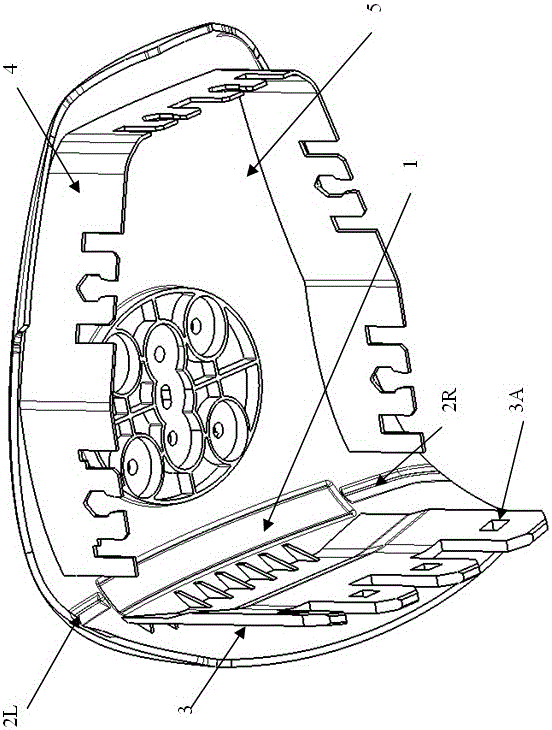

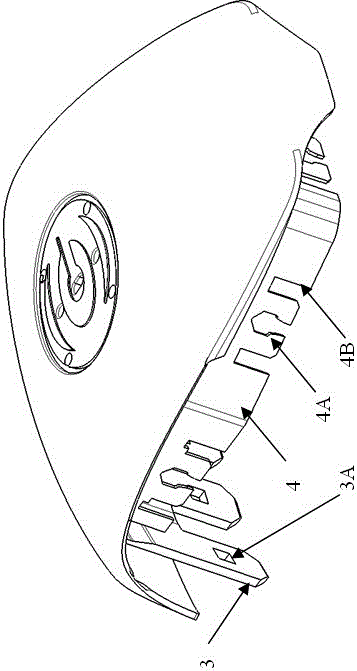

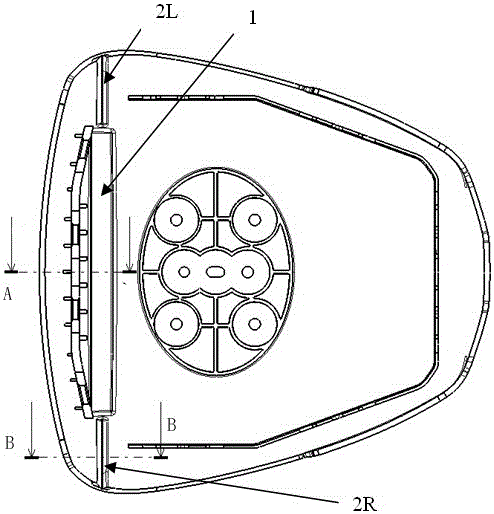

[0020] Such as figure 1 , figure 2 and image 3 As shown, the rear part of the decorative cover body 5 is provided with a square wide groove 1 to form a weakened structure, and the left and right sides of the square wide groove 1 are provided with two short weakening lines 2L and 2R, and the rear side of the square wide groove 1 is provided with a back plate 3, The decorative cover body 5 and the back plate 3 are connected as a whole through the square wide groove 1, two short weakening lines 2L and 2R are arranged on the left and right sides of the square wide groove 1, and the decorative cover body 5 is surrounded by a decorative cover wall 4, and the back plate 3 and the decorative cover wall 4 are perpendicular to the surface of the decorative cover body 5, the back plate 3 is provided with a square hole 3A, and the decorative cover wall 4 is provided with a plurality of hammer-shaped grooves 4A and guide grooves 4B.

[0021] Such as Figure 4 As shown, the material th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com