Method for measuring steel wire interval in subway shaft connection survey using electronic total station

A measurement method and technology of a total station, applied in the measurement distance, measurement device, line of sight measurement and other directions, can solve the problems of low wire spacing accuracy, measurement failure, increased measurement labor, etc., to reduce labor intensity and technical requirements, Guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described below in conjunction with accompanying drawing:

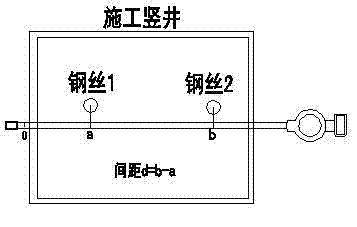

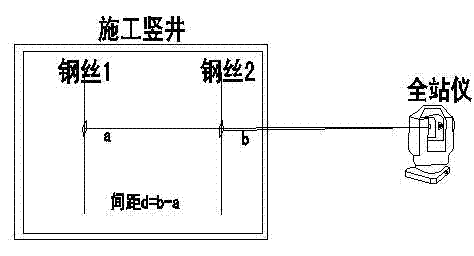

[0022] Such as Figure 3-4 As shown, the method of measuring the steel wire spacing in the connection measurement of the subway shaft by using the total station includes hanging two steel wires with a diameter of less than 0.5 mm at the mouth of the subway shaft, and immersing the heavy hammer at the end of the steel wire in the damping fluid. Include the following steps:

[0023] A. Set up the total station at the near-well point on the well and the downhole of the subway shaft respectively; paste the reflection sheet on the upper part and the downhole part of the steel wire, and make the reflection sheet be located at the place where the horizontal measurement direction of the total station is located on a straight line;

[0024] B. Adjust the offset distance of the total station relative to the straight line where the reflectors of the two steel wires are located, wherein the offse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com