Woven jacquard thermal insulation fabric

A kind of fabric and weaving technology, which is applied in the field of woven jacquard thermal fabrics, can solve the problems of thermal insulation fabrics that cannot be combined with thermal insulation and decoration, harmful to human health, and cannot be formed at one time, so as to save dyeing and printing processes, strong decoration, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

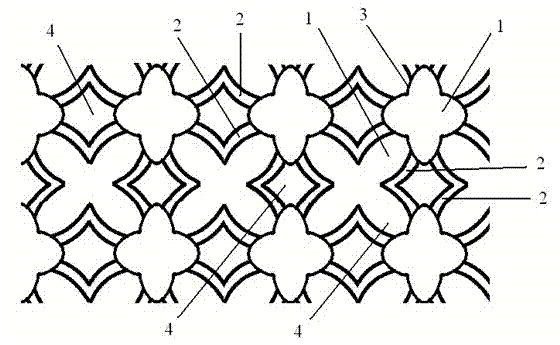

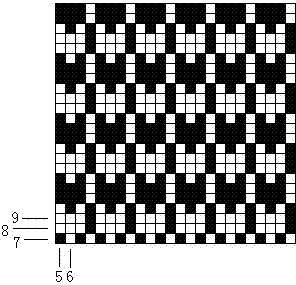

[0020] see figure 1 , a woven jacquard thermal fabric of the present invention includes 4 base blocks, wherein the first base block 1 and the fourth base block 4 are the main thermal areas, and in these two areas, the 50D Coolmax network yarn is fluffy and uniform Distributed in the middle of the two layers of tissue, a large hollow environment is formed, which can accommodate still air to the maximum extent and form an insulation layer. The second base block 2 is a dobby part, which is used to consolidate the fabric and enhance the decorativeness of the fabric. The third base block 3 is a thread point between wefts, which is used to suppress a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com