Drilling, expanding and hinge guiding device

A guiding device and a set technology, applied in reaming device, reaming device, drilling/drilling equipment and other directions, can solve the problems of inaccurate position and bell mouth, etc., and achieve the effect of high economic benefit and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

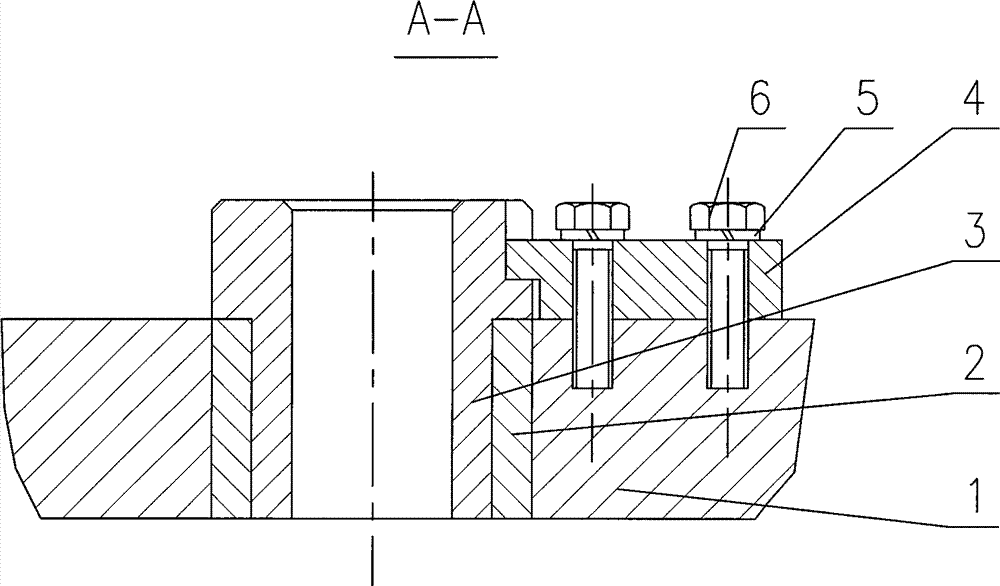

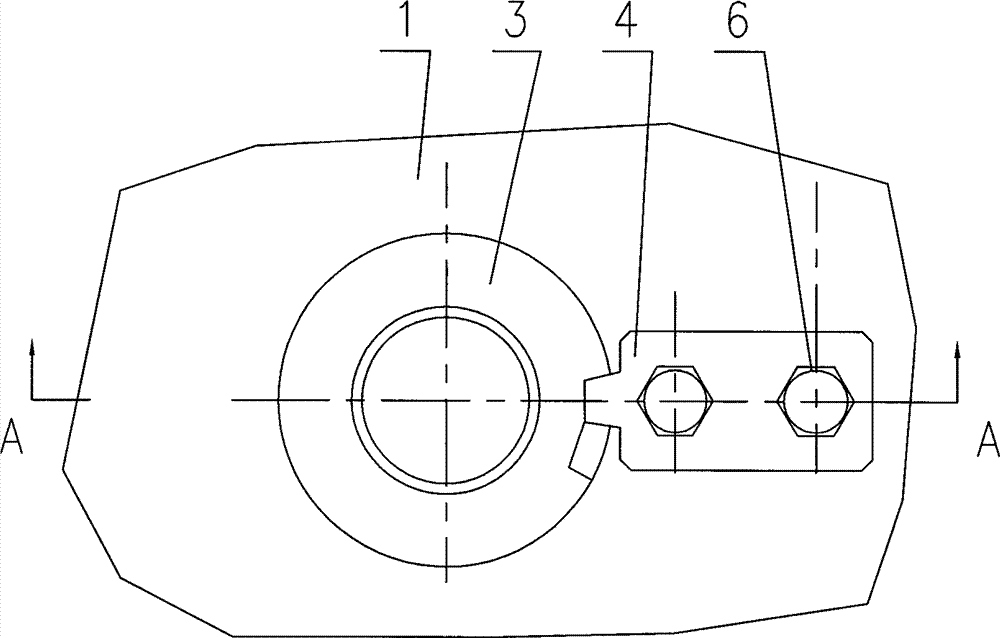

[0014] Drilling, reaming and reaming guiding device can conveniently, quickly and accurately replace the mold sets for drill bits, reamers and reamers. It is necessary to ensure that the mold sleeve cannot rotate and move up and down with the tool after it is installed. Structure is as accompanying drawing, is identical with common drilling formwork, and fixed sleeve (2) is contained in the hole of drilling formwork (1), cooperates as H7 / n6, determines the position of hole. Positioning plate (4) is fixed on the drilling template (1) with spring washer (5) and bolt (6), is the positioning element of mold cover. The quick-change sleeve (3) is fitted in the hole of the fixed sleeve (2) through the outer circle and the groove of the quick-change sleeve (3) to fit H7 / g6. The quick-change sleeve (3) is rotated so that the facade of the quick-change sleeve (3) contacts the corresponding surface of the positioning plate (4), so as to limit the rotation and up-and-down movement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com