Food mixing machine

A food mixer and food technology, applied in the field of food mixers, can solve problems such as low work efficiency, high production cost, and low processing efficiency, and achieve the effects of improving mixing efficiency, increasing mixing area, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

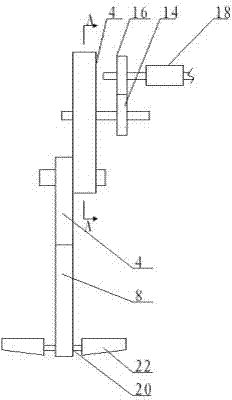

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

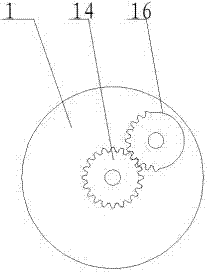

[0025] Such as figure 1 As shown, in the first embodiment of the present invention, a container 10 for holding food and a stirring rod 8 arranged above the container 10 are included. Rocking bar 6, runner 1 and rocking bar 6 are all hinged on a connecting rod 4, and the lower end of connecting rod 4 is fixedly connected with stirring bar 8. When the runner 1 rotates, the connecting rod 4 swings back and forth, and the end point of the stirring rod 8 fixedly connected to the connecting rod 4 moves in a closed curve, so that the stirring rod 8 can automatically stir in the container 10. ,Improved work efficiency. The stirring rod 8 can also be arranged in a curved shape, thereby increasing the stirring area and improving the stirring efficiency. For some food raw materials that also need to be broken while rotating, a rotating shaft 20 that passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com