Full-automatic square pancake flipping machine

A fully automatic pancake machine technology, applied in the direction of baking pancakes, oil/fat baking, etc., can solve the problems of cumbersome process and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

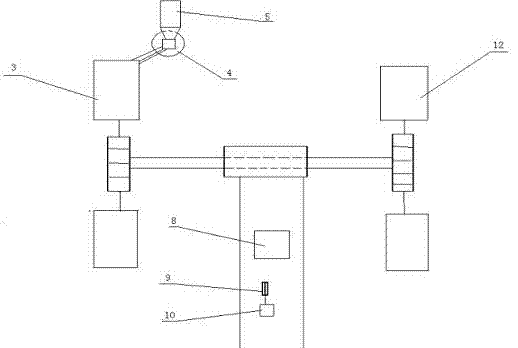

[0018] The present invention will be described in detail with reference to the accompanying drawings.

[0019] refer to Figure 10 Each device is in the working position. At this time, the cleaning and oiling device is in the stand-by state. Turn on the main power switch and start to start. The cylinder (27) on the spreading and scraping device stretches out to drive the mobile platform, and drives the platform casters (26) along the track. (24) move forward, and at the same time the oil cylinder (28) starts to lift the lifting arm (33), and the lifting arm (33) is adjusted to a balanced state under the repulsion of the same pole of the permanent magnet (29) (42), preventing the lifting arm from moving forward When it tilts and collides with the turntable.

[0020] When the mobile platform reaches the preset position, the travel switch is triggered, the cylinder (27) stops working, and the mobile platform stops running. At the same time, the oil cylinder (28) retracts, the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com