Hydraulic filter element and related method of manufacture

A filter element and hydraulic technology, which is applied in the field of manufacturing such hydraulic filter elements and oil filter elements, can solve problems such as installation and removal costs, high time costs, etc., to reduce costs, improve functionality, and prevent damage or destruction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

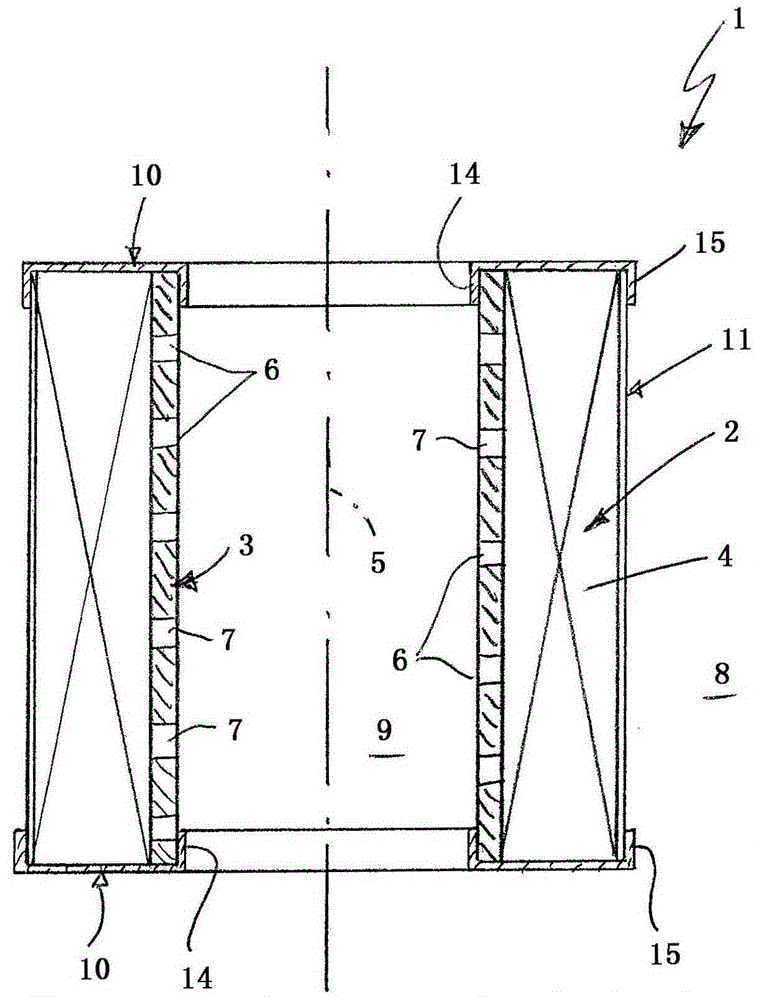

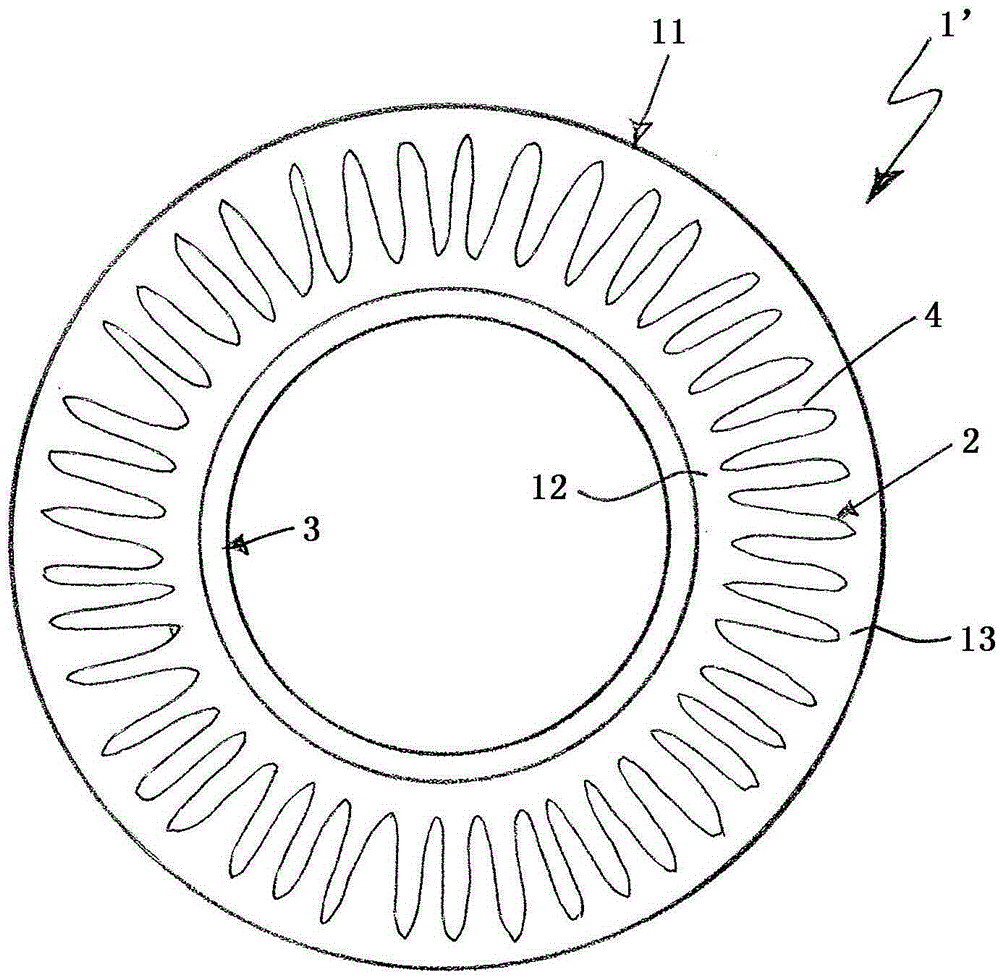

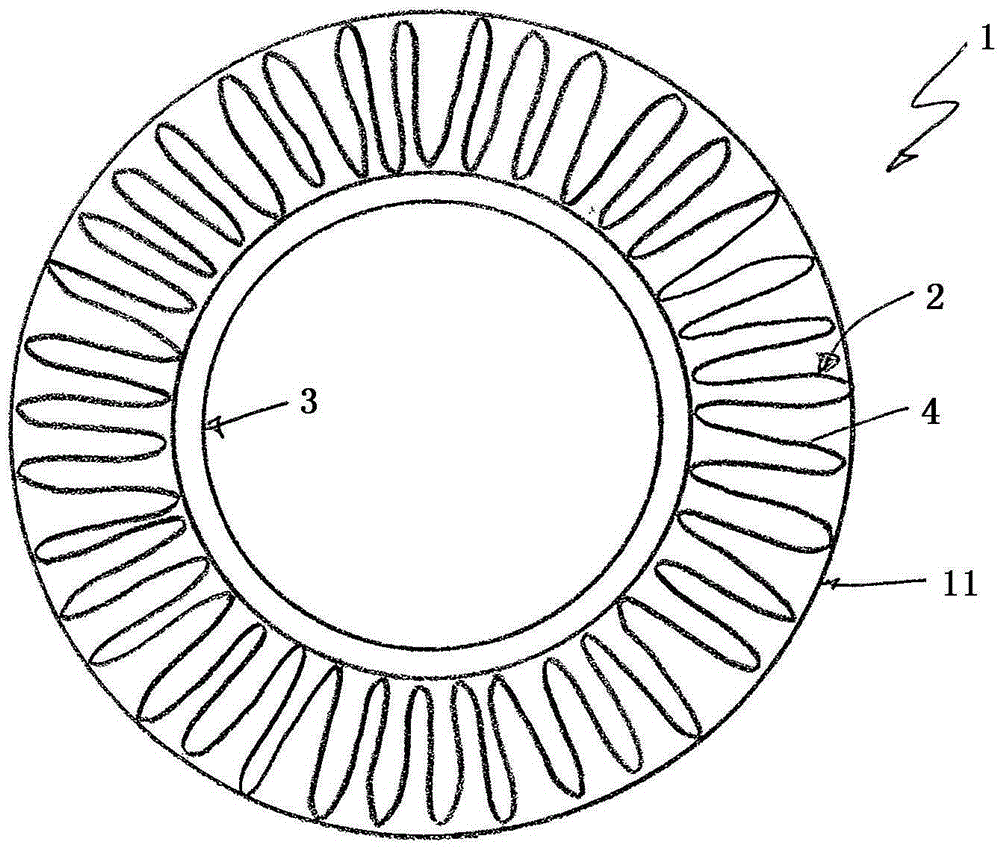

[0032] and Figure 1 to Figure 3 Correspondingly, the hydraulic filter element 1 , which may preferably be an oil filter element, comprises a cylindrical filter body 2 and a cylindrical inner frame 3 . The filter body 2 is produced by means of a star-shaped folded filter material 4 . The inner frame 3 is arranged coaxially with the filter body 2 , wherein the filter body 2 surrounds the inner frame 3 . exist figure 1 The common longitudinal center axis is marked with reference numeral 5 . The inner frame 3 is designed to be permeable to the respective hydraulic medium, especially oil. For this purpose, the inner frame can be formed with a perforation 6 consisting of a plurality of individual through-openings 7 . The filter body 2 is supported radially inwardly on the inner frame 3 . The filter body 2 can thus withstand a relatively large pressure difference between the external raw space 8 and the internal clean space 9 during operation.

[0033] In the example, hydrauli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com