Crossed bracket with I-shaped section

A technology of cross-shaped brackets and cross-sections, which is applied in the field of cross-shaped brackets, can solve the problems of narrow installation space and low integration, and achieve the effects of good anti-vibration performance, high precision requirements, and simple production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

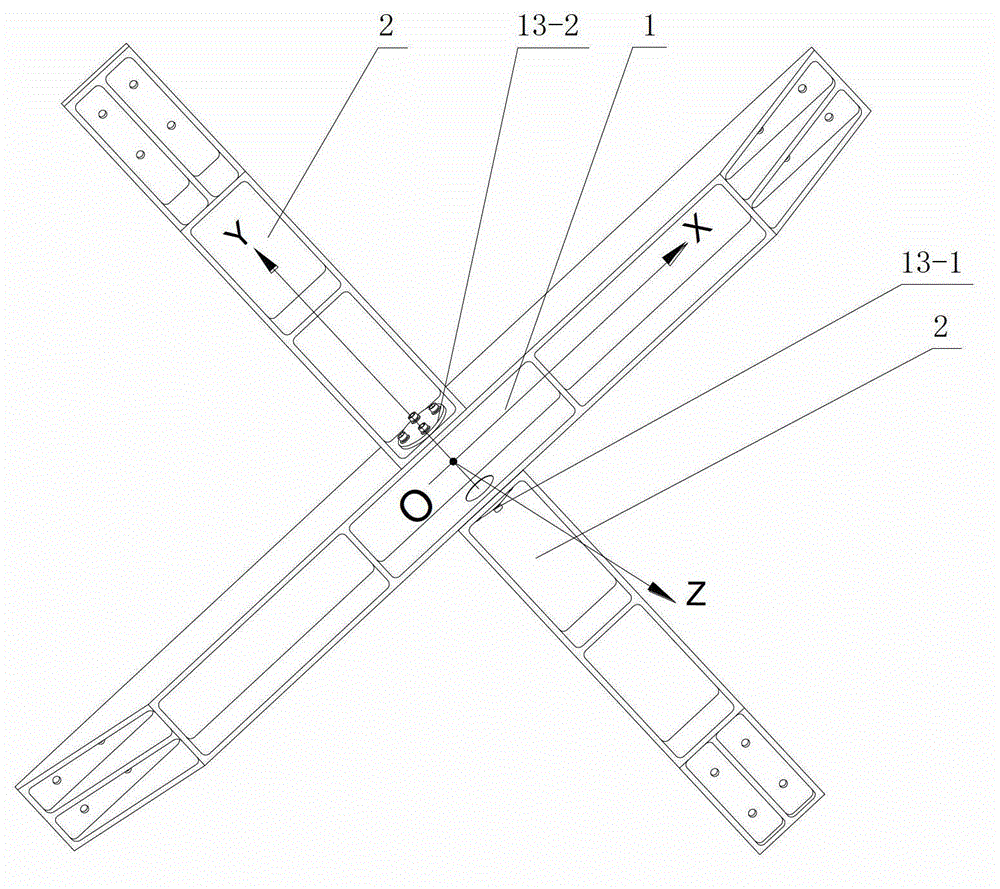

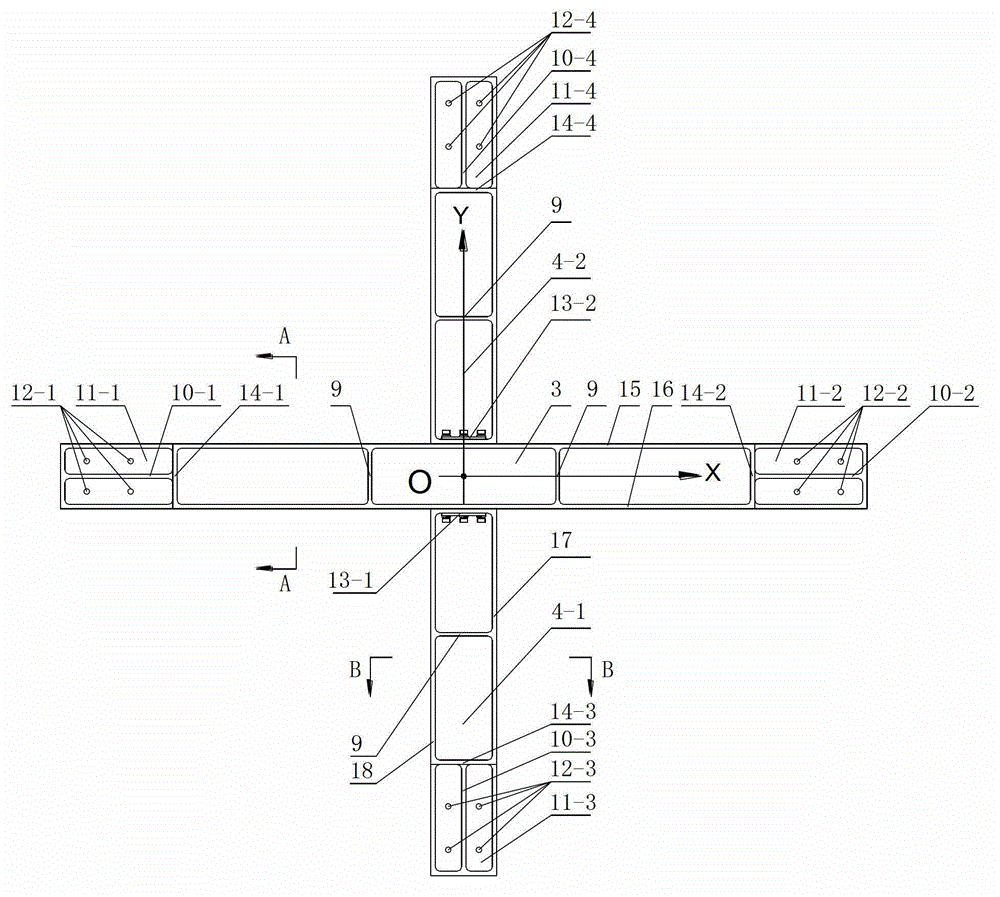

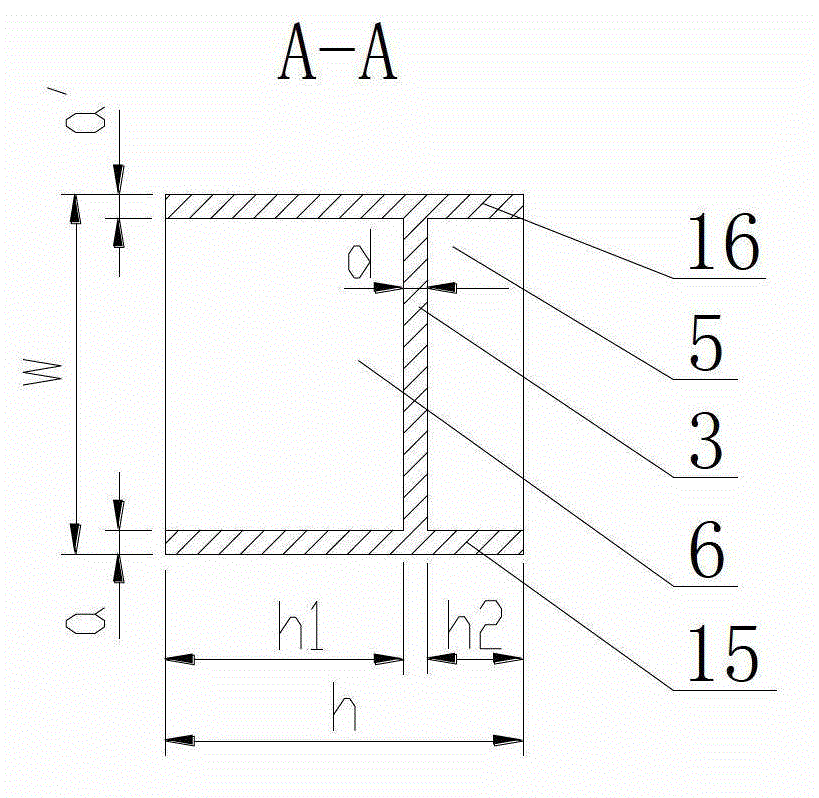

[0019] Now in conjunction with the accompanying drawings, the present invention is further explained;

[0020] The present invention: comprises long arm support (1), 2 short arm supports (2), long arm separation surface (3), short arm separation surface (4), wherein, short arm separation surface (4-1,4-2 ), long arm separation surface bottom (5), long arm separation surface top (6), short arm separation surface bottom (7), short arm separation surface top (8), ribs (9), end ribs (10 ) wherein, including long arm end reinforcing ribs (10-1, 10-2), short arm end reinforcing ribs (10-3, 10-4), end mounting surface (11), wherein, end mounting surface ( 11-1,11-2,11-3,11-4); end mounting holes (12), wherein, end mounting holes (12-1,12-2,12-3,12-4), connected Shaft (13), wherein, shaft coupling (13-1, 13-2); sealing surface (14), wherein, long arm sealing surface (14-1, 14-2), short arm sealing surface (14- 3), right-angle side panels (14-4), long arm bracket side panels a(15), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com