Locking gear insulation temperature measuring device for motor end cover

A technology of motor end caps and locking teeth, applied in electrical components, electric components, electromechanical devices, etc., can solve the problems of bearing current corrosion, loose insulation support, easy to loose, etc., to improve processing performance, overcome Easy to loosen and prevent the effect of current corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

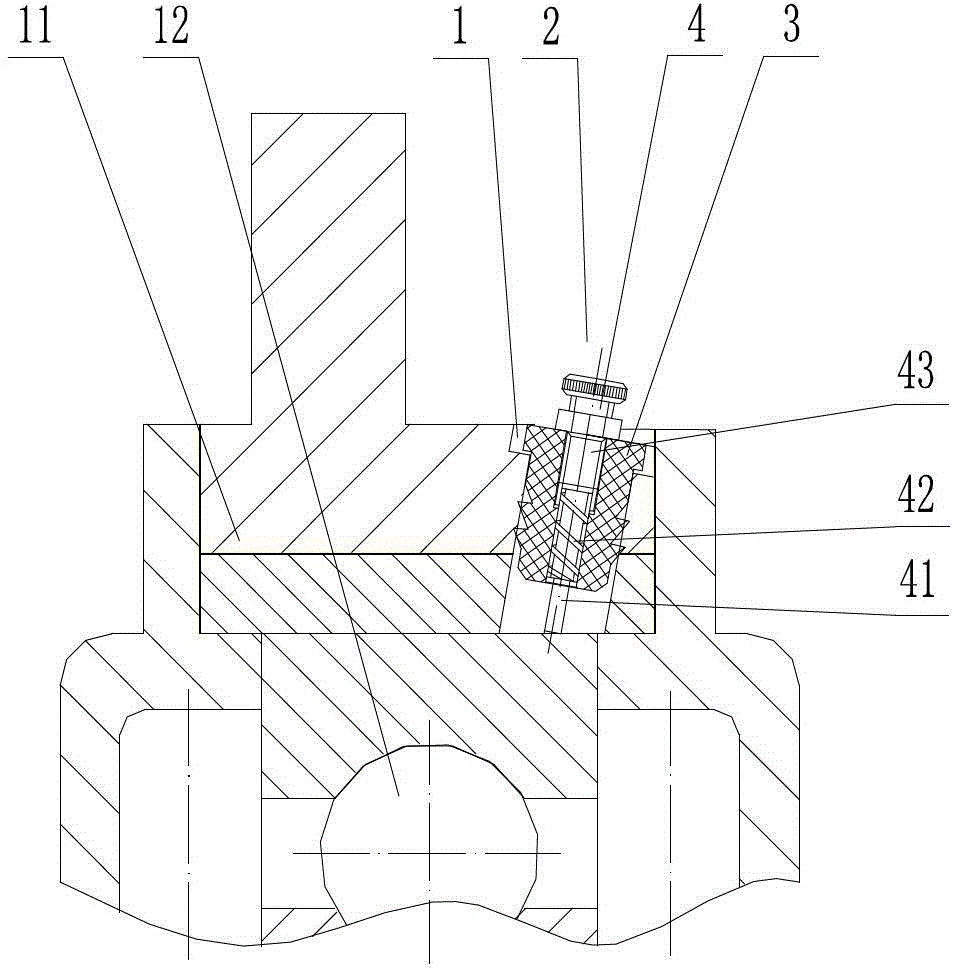

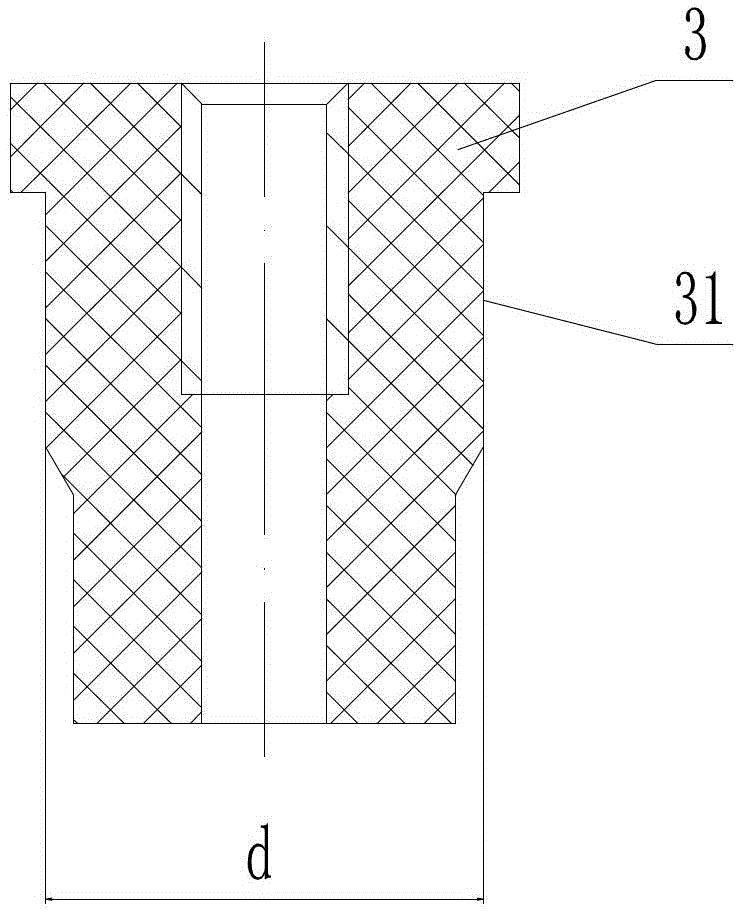

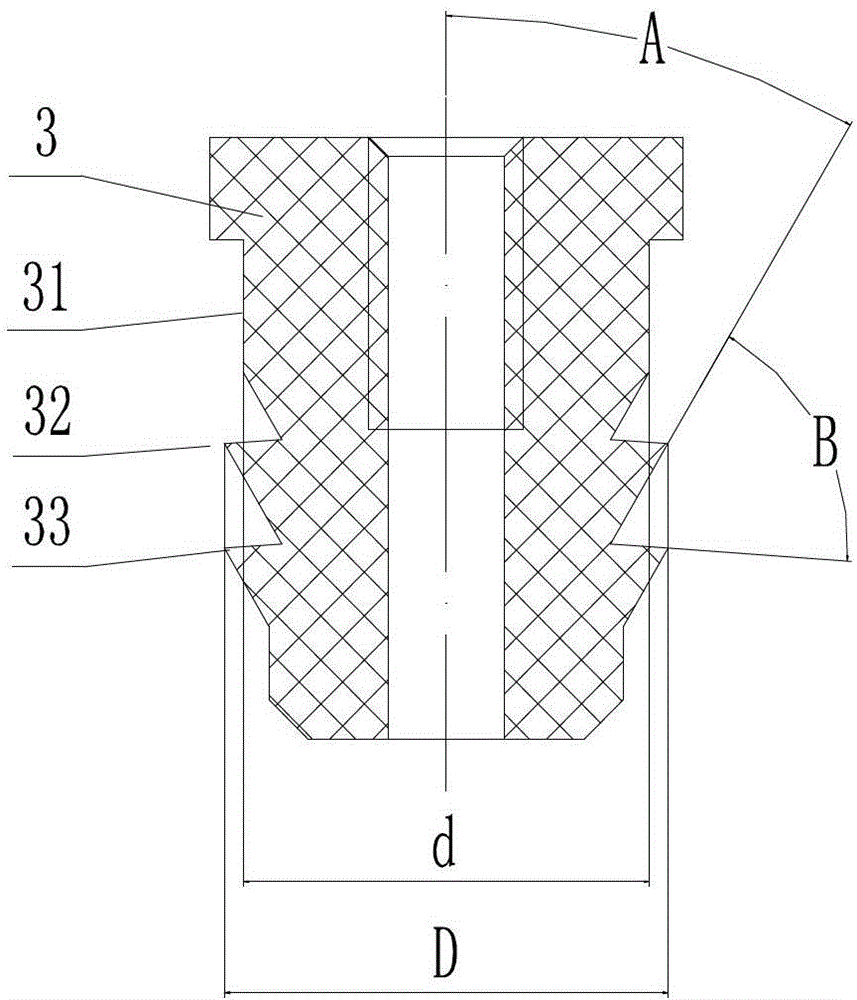

[0025] In conjunction with the accompanying drawings, the working principle of the present invention: a locking tooth type insulating temperature measuring device for a motor end cover of the present invention, it installs an insulating temperature measuring device 2 in the hole 1 of the motor end cover and passes through the insulating support therein Part 3 fixes the temperature measuring element 4 in the motor end cover 11 to realize the timely control of the temperature rise of the motor and the shaft current. Since the insulating support part 3 is made of high insulation grade polytetrafluoroethylene material, it is made into a locking tooth type insulation Stopper, if the stopper-type insulating support 3 is only provided with a positioning cylinder 31 according to its traditional structure and process, even if it is installed with an interference fit, it will not be able to overcome the force of the spring 42 in the temperature measuring element 4 due to the influence of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com