Automatic running and pulling system of oilfield workover string

A pipe string and oil pipe technology is applied in the field of automatic tripping and tripping system of oil field workover pipe strings to achieve the effects of enhancing adaptability, reducing the number of connecting wires, and changing the way of workover operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

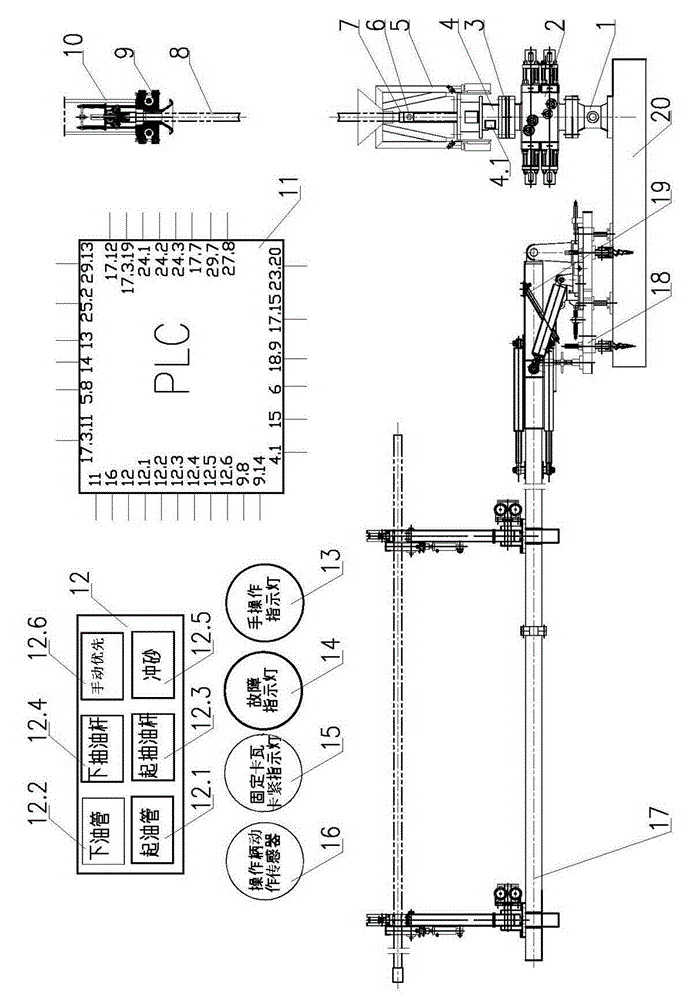

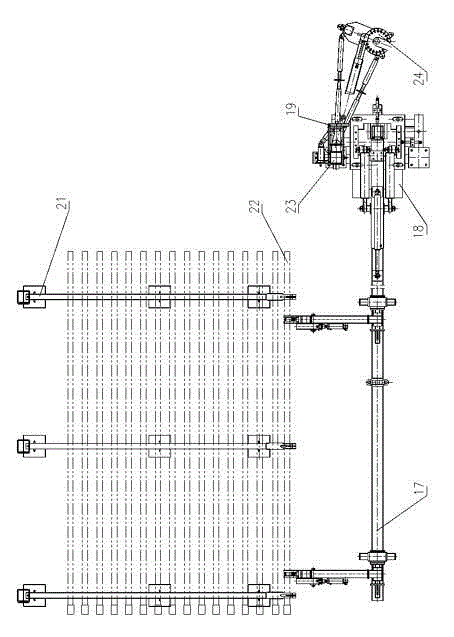

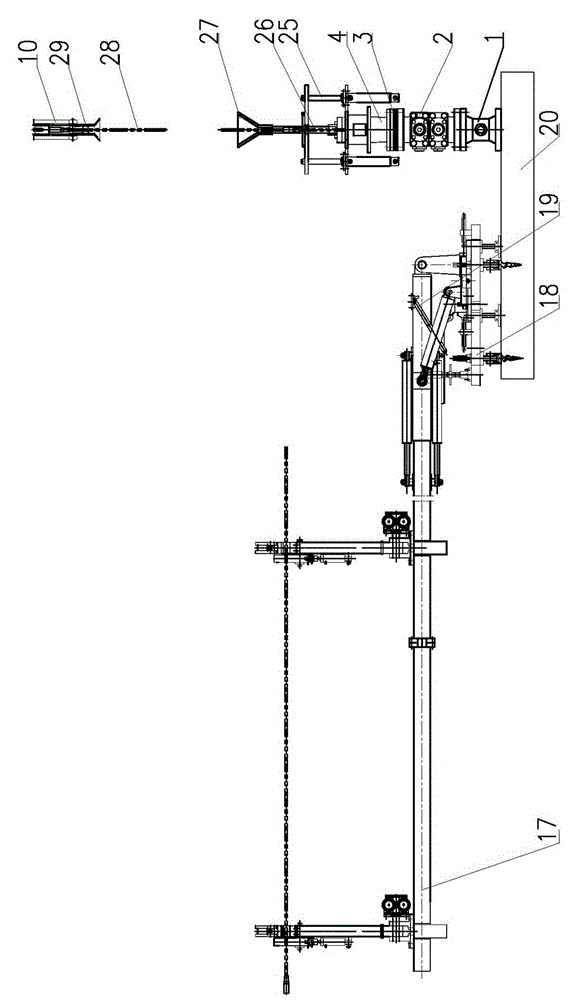

[0050] Below with reference to accompanying drawing, further describe:

[0051] According to an embodiment of the present invention such as Figure 1 to Figure 28 As shown, 1 is the tubing head, 2 is the blowout preventer, 3 is the self-sealing sealing device, 4 is the fixed slip, 5 is the tubing guiding mechanism, 6 is the wellhead coupling positioning sensor, 7 is the wellhead tubing, 8 is the suspension 9 is the oil pipe elevator assembly, 10 is the lifting ring, 11 is the PLC programmable controller, 12 is the operation panel, 13 is the manual operation indicator light, 14 is the fault indicator light, 15 is the fixed slip clamping indicator light, 16 is the operation handle motion sensor, 17 is the mechanical arm assembly, 18 is the base assembly, 19 is the linkage assembly, 20 is the ground foundation, 21 is the pipe string bent frame, 22 is the horizontal oil pipe, 23 is the hydraulic clamp bracket, 24 is the oil pipe hydraulic pressure Pliers, 25 is the sucker rod for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com