Underframe structure for a motor vehicle

A bottom structure and motor vehicle technology, applied in substructure, superstructure, subassembly of superstructure, etc., can solve problems such as complex costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

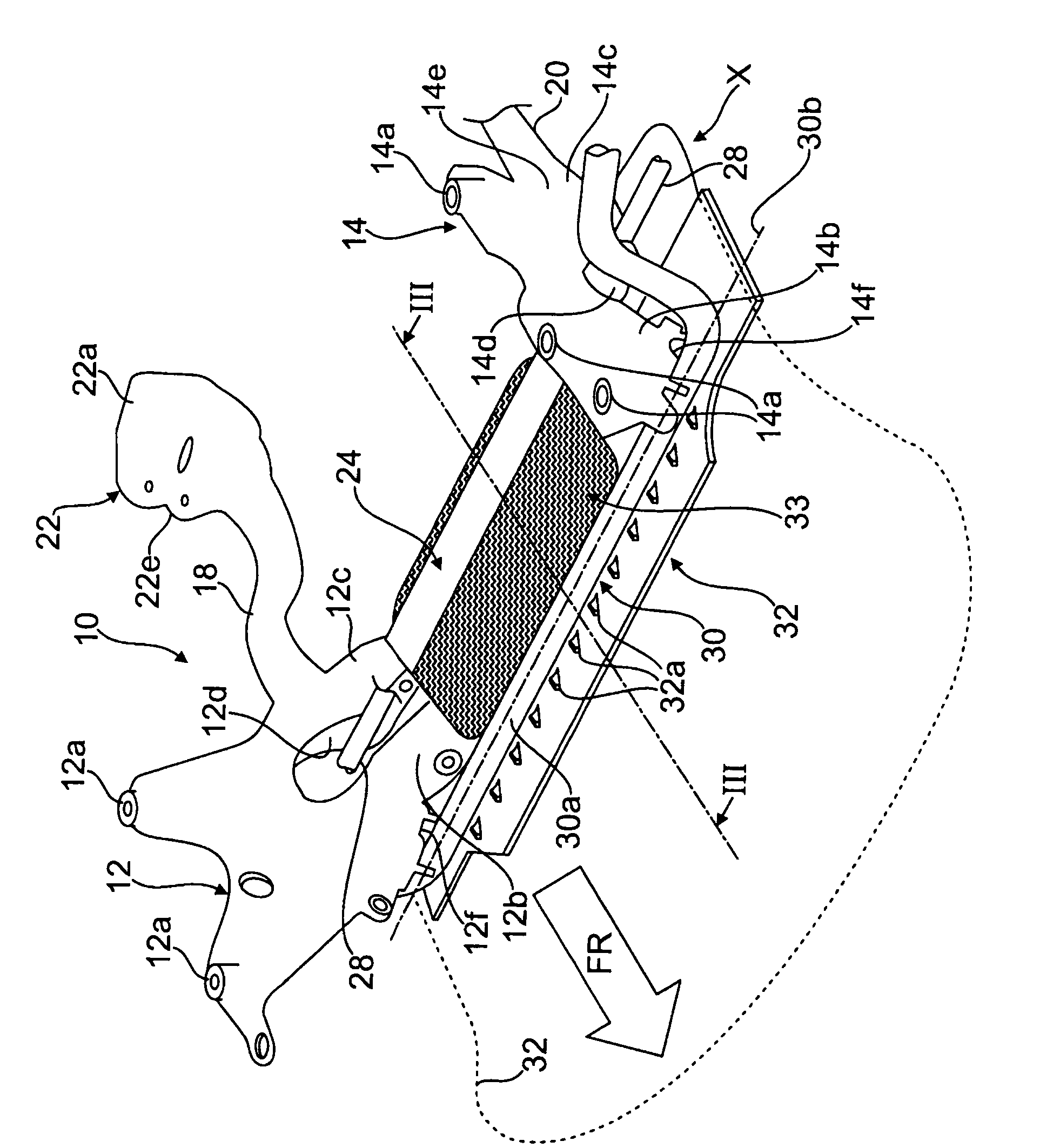

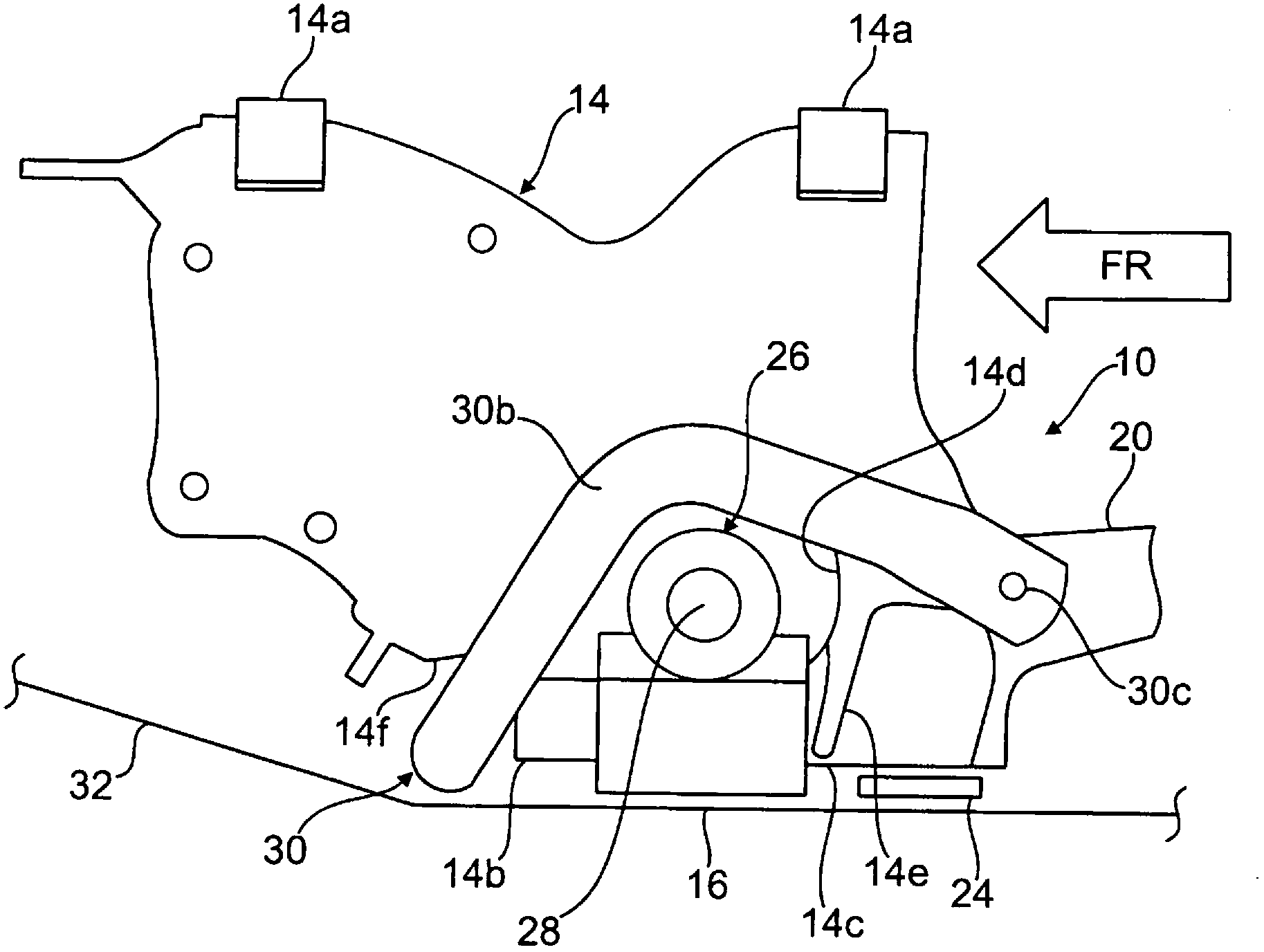

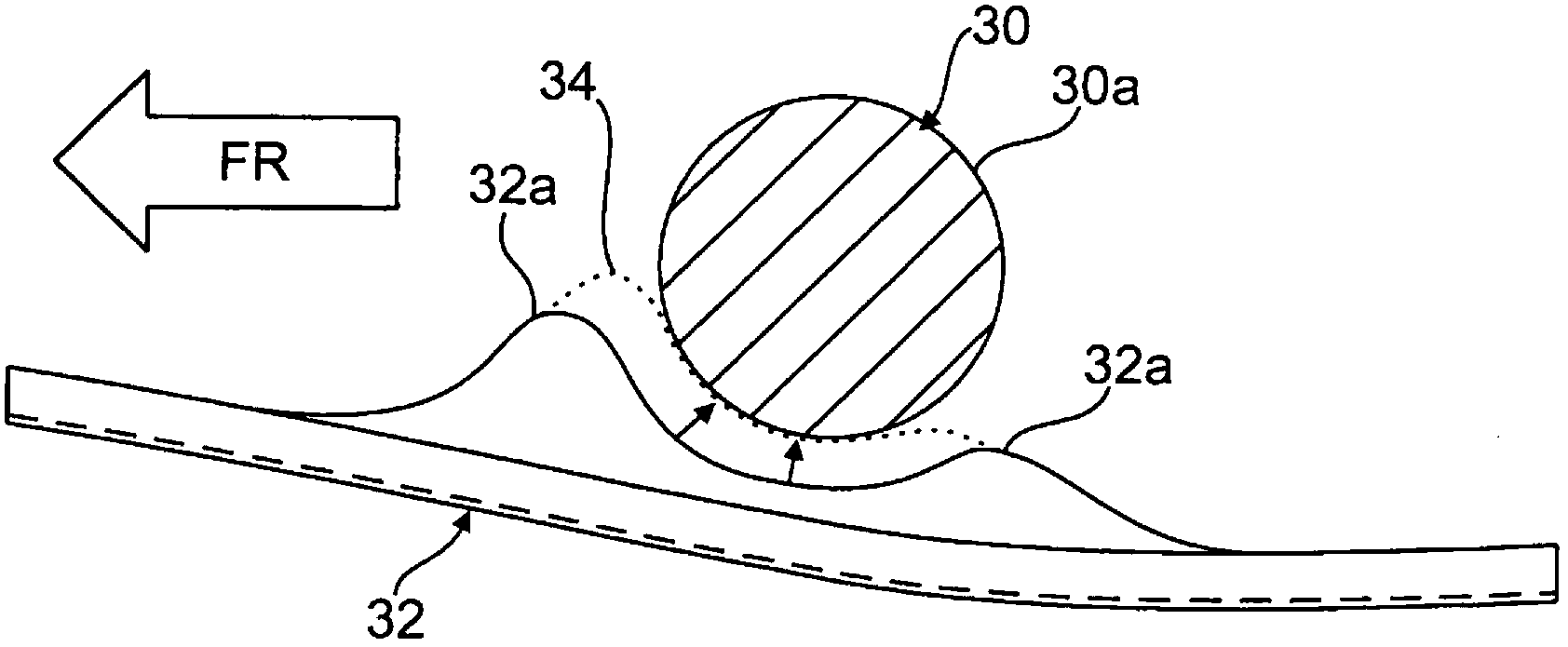

[0023] figure 1 "10" in the middle indicates the auxiliary frame 10 used for the front bottom structure of the motor vehicle. Rearwardly directed longitudinal, in particular pipe sections 18 , 20 and finally also plate-shaped lower cross braces 24 as cross beams reinforcing the sub-frame 10 , which is here designed in a U-shape, consist of the pipe sections 18 , 20 With formed functional nodules, especially casting nodules 22 (in figure 1 Only the casting nodule 22 on the right can be seen in , the casting nodule on the left is identically implemented in a mirror image).

[0024] The frame guide heads 12 , 14 and the end-side cast nodes 22 have fastening flanges 12 a , 14 a , 22 a via which the subframe 10 is bolted to a longitudinal member (not shown) of the body of the motor vehicle.

[0025] For example, the downwardly and inwardly projecting support arms 12b, 12c and 14b, 14c are firmly bolted to the cross brace 24 by means of fixing bolts (not shown), said support arms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com