Sand flow model test system for drop tower platform

A technology of flow model and test system, which is applied in the field of sand flow simulation test system, can solve problems such as lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

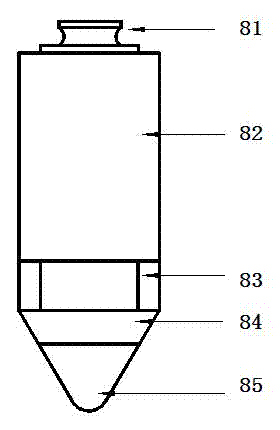

[0030] Based on the drop tower platform and according to the characteristics of the drop tower test system, the present invention designs and develops a set of model test system suitable for microgravity drop tower test. The drop chamber is the main place for the drop tower test. Compared with the test under conventional gravity, the special limitations of the drop tower equipment need to be considered in the microgravity test in the drop tower. In this embodiment, a single cabin is used for the microgravity test, and the load space in the cabin is a cylindrical space with a diameter of 850 mm and a height of 1000 mm. Therefore, the overall experimental equipment of the system of the present invention must adapt to this space limitation, such as figure 1 The shown schematic diagram of the structure of a single cabin includes a suction head 81, a cabin body 82, an in-chamber test platform 83, an in-chamber power supply 84, and a shroud 85 from top to bottom. Since the method of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com