Process and device for manufacturing vitrified tiles with triple cloths and imitation jade textures

A technology of imitating jade and vitrified bricks, applied in the direction of manufacturing tools, supply devices, etc., to achieve the effect of a wide range of designs, natural and smooth texture lines, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

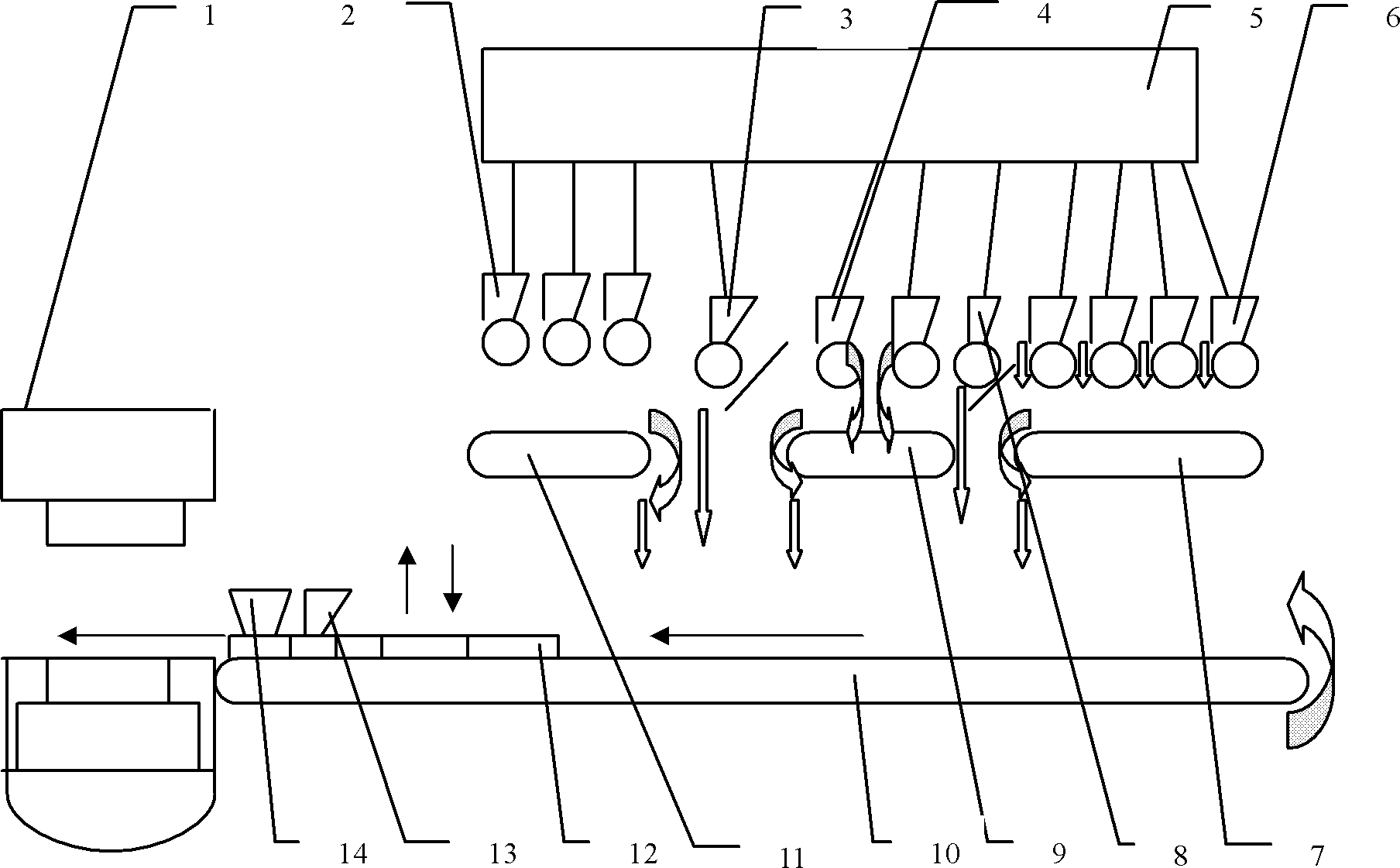

[0022] A kind of technology of making three times cloth imitation jade texture vitrified brick, its used technology equipment such as figure 1 As shown, the process device includes a stacking overall conveying device, a powder beating device for making micronized powder, a combined micron powder unloading device, and a blanking conveying device. The blanking conveying device is above the overall stacking conveying belt 10, the micropowder combination device is above the blanking conveying device, and the device 5 for beating and making micropowder is at the top of the entire equipment system. The micropowder combination blanking device includes a combination micropowder structure 2, a combination crystalline micropowder structure 6, a pair of micropowder structure components 4, and the blanking conveying device includes a combined crystalline micropowder conveyor belt 7, the first line blanking roller device 3, the second Line blanking drum device 8 and vibrating sieve, to fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com