Pulse deuterium fluoride (DF) laser device main engine structure with molecular sieve adopted for processing

A technology of molecular sieves and lasers, applied in lasers, phonon exciters, laser components, etc., can solve problems such as explosives, continuous wave lasers with large structures, and low reliability, and achieve high average power laser output and average power The effect of laser output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

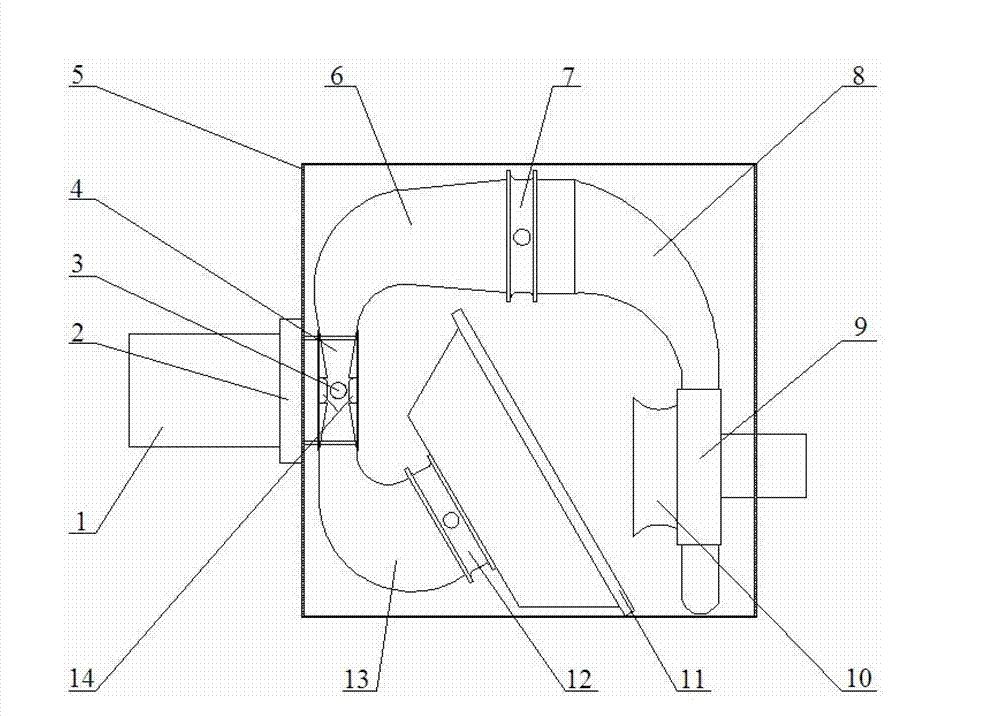

[0010] Specific implementation mode one, combination figure 1 In this embodiment, the main structure of the pulsed DF laser with molecular sieve processing is described, including the pump source 1, the insulating plate 2, the resonant cavity 3, the discharge cavity 4, the housing 5, the upper left runner cavity 6, the first heat exchanger 7, and the right Upper flow channel cavity 8, fan 9, bell mouth 10, molecular sieve 11, second heat exchanger 12, lower flow channel cavity 13, discharge electrode 14; the pump source 1 is connected to the discharge electrode 14 through the insulating plate 2; the upper left flow channel The cavity 6 is connected to the upper end of the discharge cavity 4 through a flange, and the air flow is introduced into the discharge cavity 4; the first heat exchanger 7 is respectively connected to the upper left runner cavity 6 and the upper right runner cavity 8 through the flange, and a rubber gasket is added at the connection , Used to adjust the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com