Oil pump device

A technology for oil pumps and pump housings, which is applied in the field of oil pump devices, and can solve problems such as difficulty in forming an output motor, increased driving force loss of the motor, and increased sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

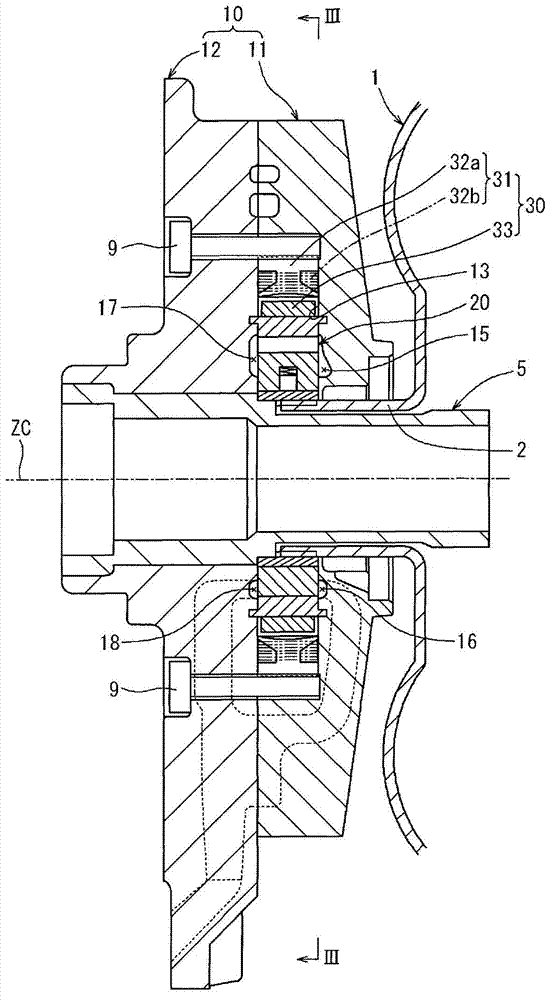

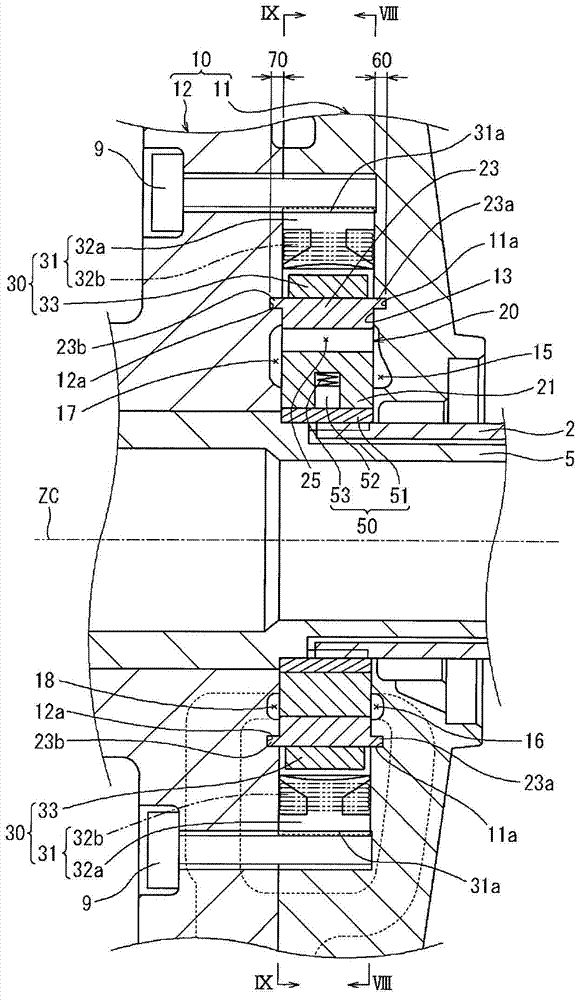

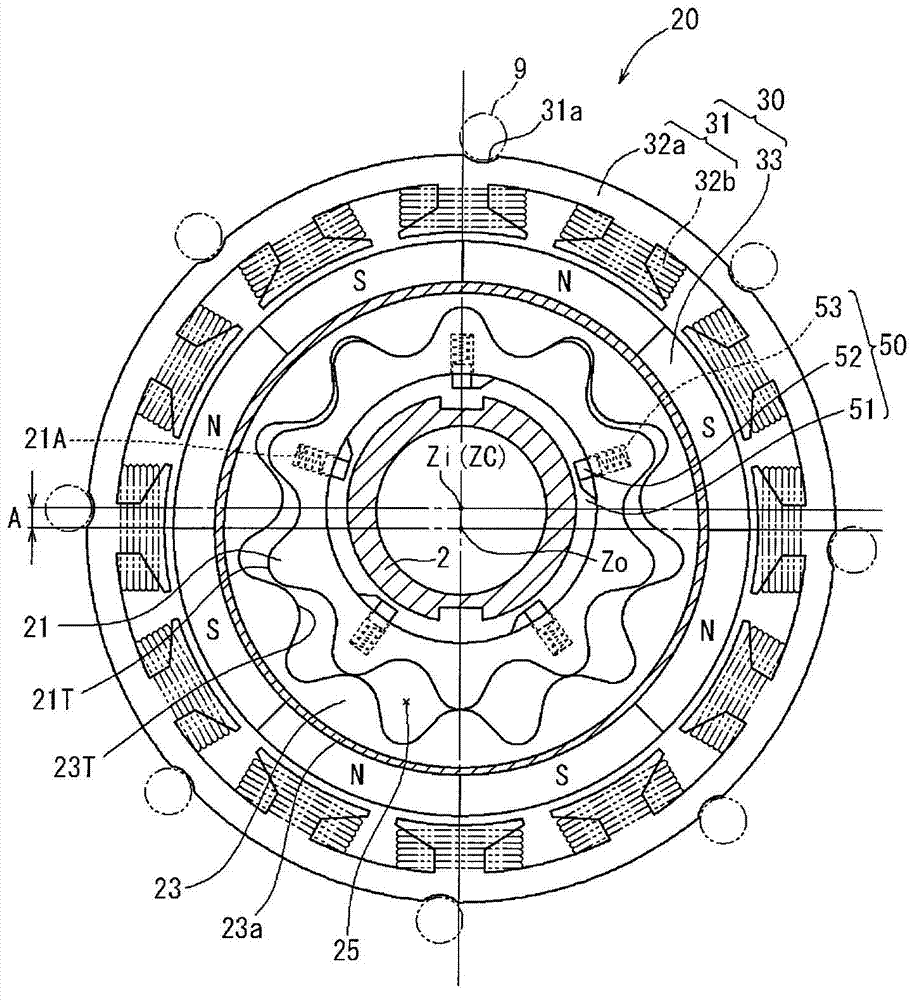

[0019] according to Figure 1 to Figure 7 , the oil pump device according to the embodiment of the present invention will be described.

[0020] like figure 1 As shown, the oil pump device is assembled in the hydraulic torque converter 1 of the automatic transmission. In the oil pump device, the pump housing 10 is fixed to a housing (not shown) of an automatic transmission with bolts. The pump housing 10 is constructed so that the bolts 9 are used to figure 1 The first housing 11 divided in the middle and left and right is combined with the second housing 12 . Between the first housing 11 and the second housing 12, a pump assembly space 13 is formed. More specifically, the pump assembly space 13 consists of an assembly recess formed axially recessed at the center of the inner wall surface of the first housing 11 that faces the second housing 12 , and an assembly recess of the second housing 12 that is aligned with the second housing 12 . A housing 11 is formed on opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com