Weft yarn curve tatting fabric weaving method and dedicated elastic free reed

The technology of weft curve and woven fabric is applied in the field of weft curve woven fabric, weaving method and special device, which can solve the problems of single variety and color of woven fabric, and achieve the effect of improving the variety and grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

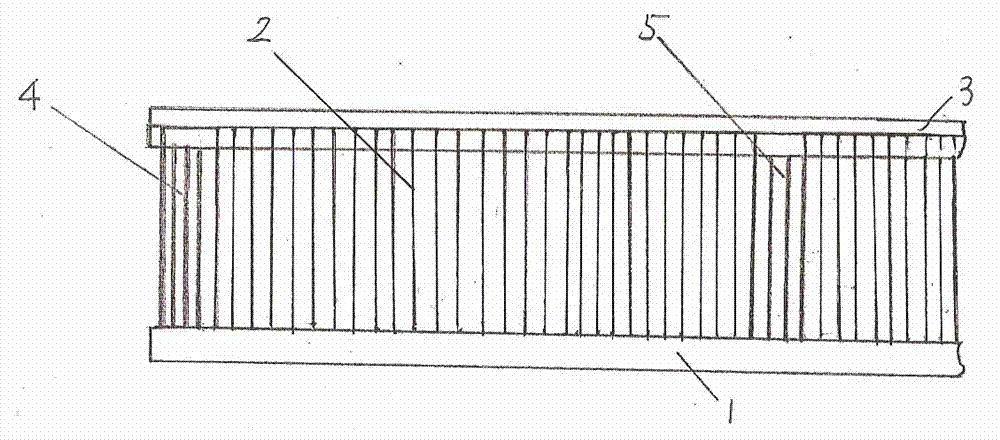

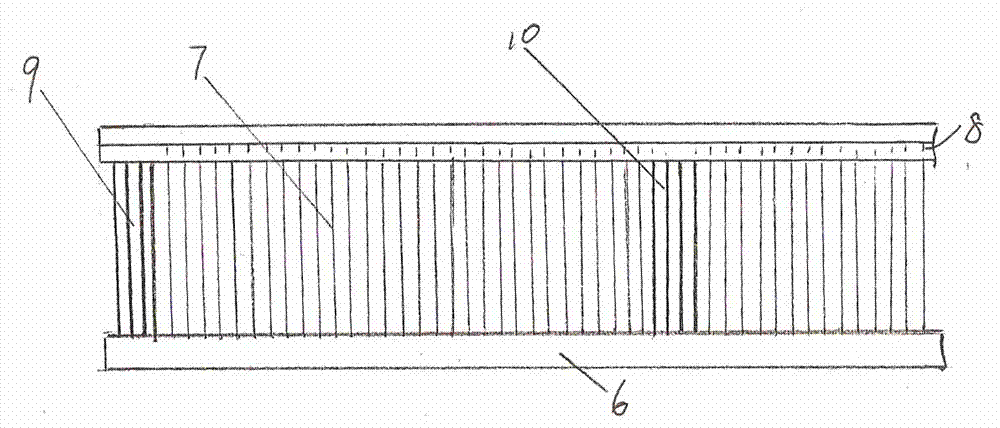

[0016] A weaving method for weft curve woven fabrics, comprising warp let-off, shedding, weft insertion, beating-up, and take-up, wherein reed teeth are used to bend elastic free reeds according to the magnitude of beating-up force during beating-up; utilizing changes in fabric weave or The change in the thickness of the weft yarn causes the difference in the filling rate of the fabric on the same line in the weft direction on the loom, resulting in a difference in the beating force. If the filling rate is large, the reed teeth will have large bending, and if the filling rate is small, the reed teeth will have small bending to realize the weft curve; the weft yarn of the prepared fabric is curved.

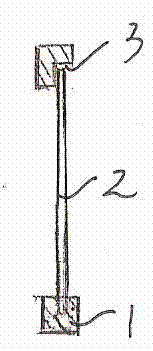

[0017] The elastic free reed includes a reed base 1 on which movable reed teeth 2 are mounted, the lower ends of the movable reed teeth are fixedly connected to the reed base, and the upper ends of the movable reed teeth are movably arranged on the reed tooth positioning groove 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com