Method for reducing particulate emissions on a direct-injection petrol engine

An engine, direct technology, applied in the direction of engine components, engine control, combustion engine, etc., can solve problems such as damage to energy supply, and achieve the effect of limiting energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

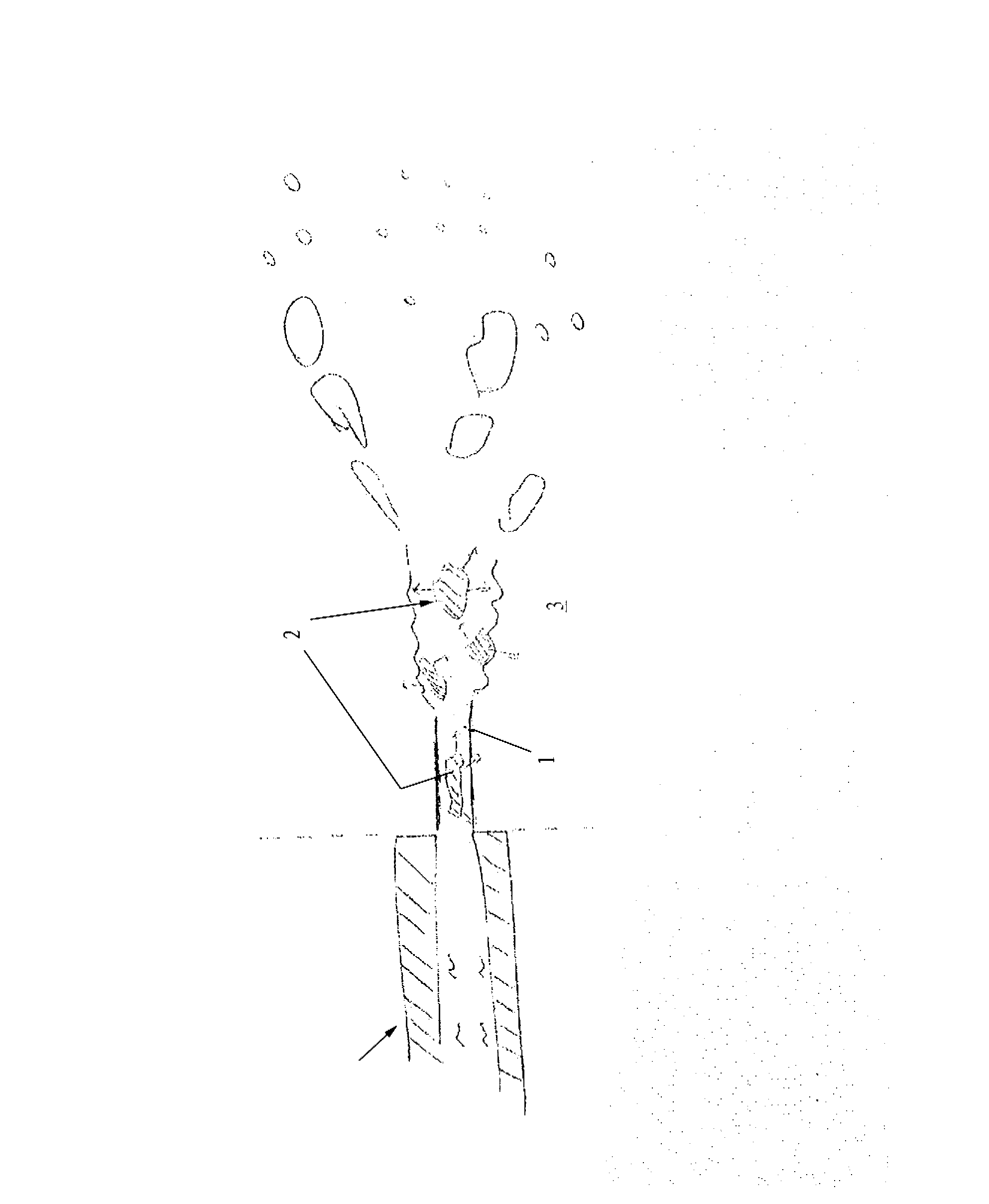

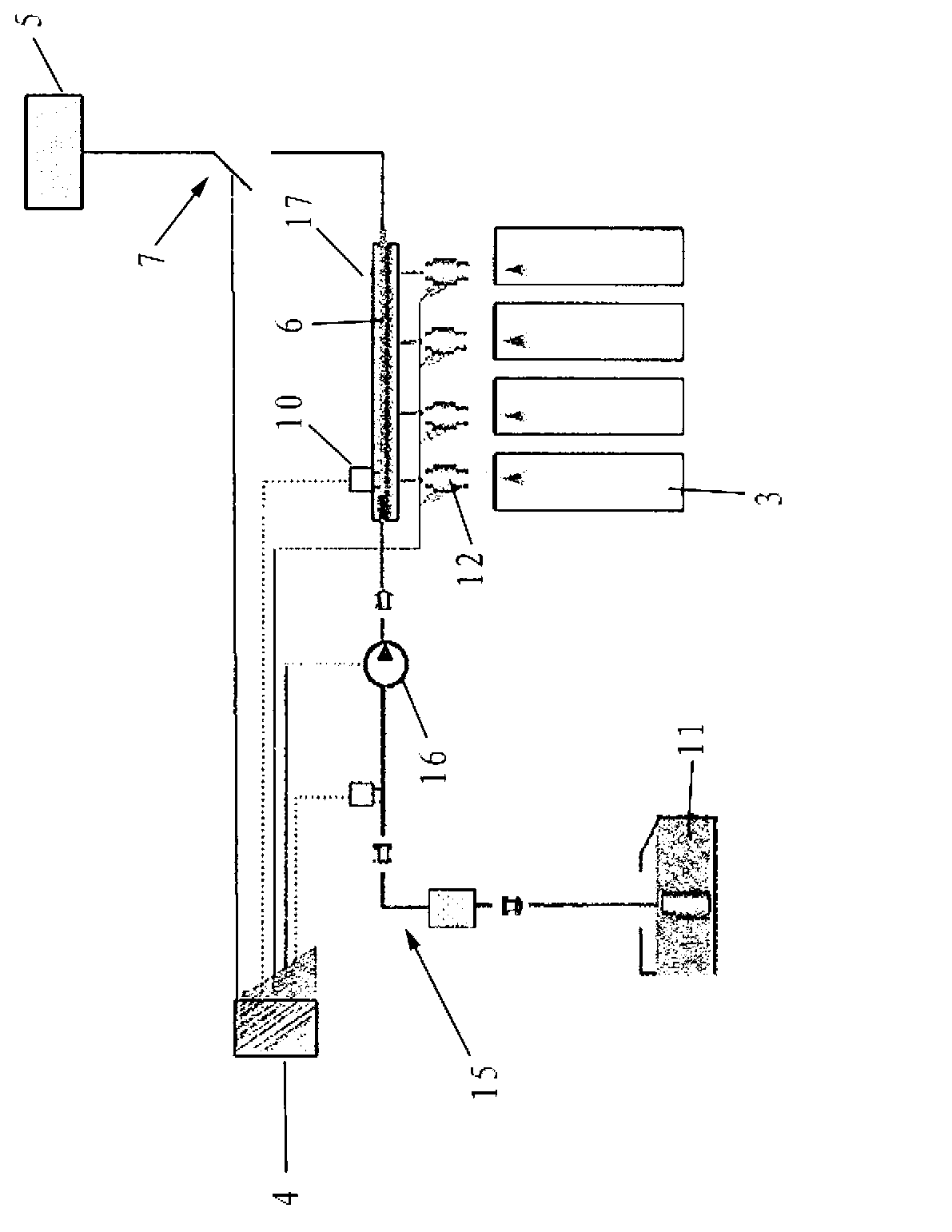

[0035] The invention relates firstly to a method for controlling an engine operating with direct injection of fuel, in particular gasoline, into the combustion chamber of the engine, with the aim of reducing the amount of particles emitted by the engine. In particular, it will relate to stratified-charge engines.

[0036] By particles is meant solid compounds formed during the combustion taking place in the combustion chamber. In other words, these are solid products of the chemical reactions that take place in the combustion chamber between the fuel and the oxidant, and originate in particular from fractions of liquid fuels subjected to high temperatures.

[0037] According to the invention, the operating phase of the engine, in particular the operating point and / or the phase-of-life point, is determined and, according to the found operating phase, the fuel is injected into the combustion chamber before it is introduced into the combustion chamber. heating.

[0038] In orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com