Lifting mechanism of electric shovel

A technology of electric shovel and sun gear, applied in the direction of spring mechanism, hoisting device, etc., can solve the problems of large floor space and heavy weight, and achieve the effect of reducing equipment weight, reducing volume and large transmission ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

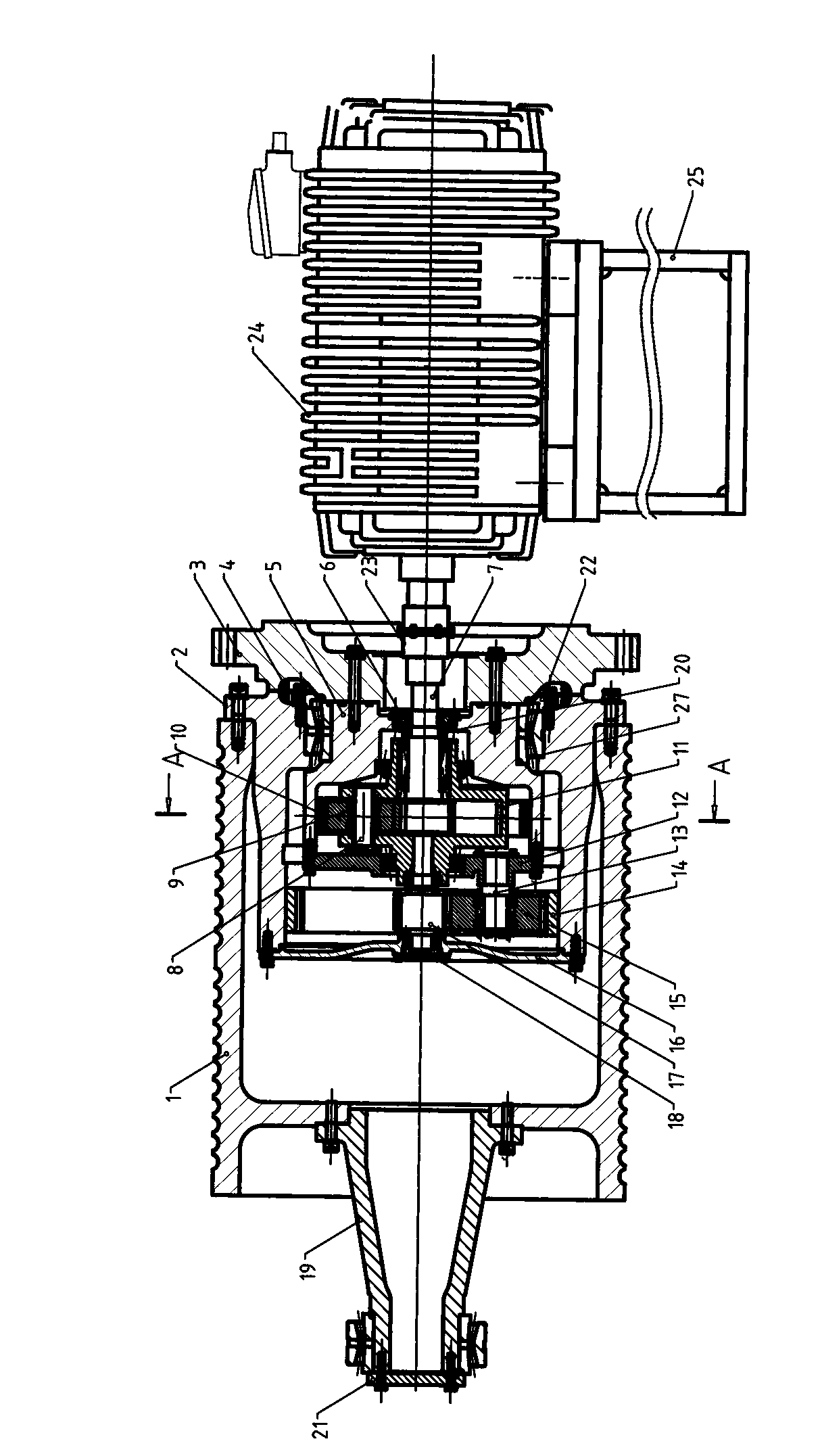

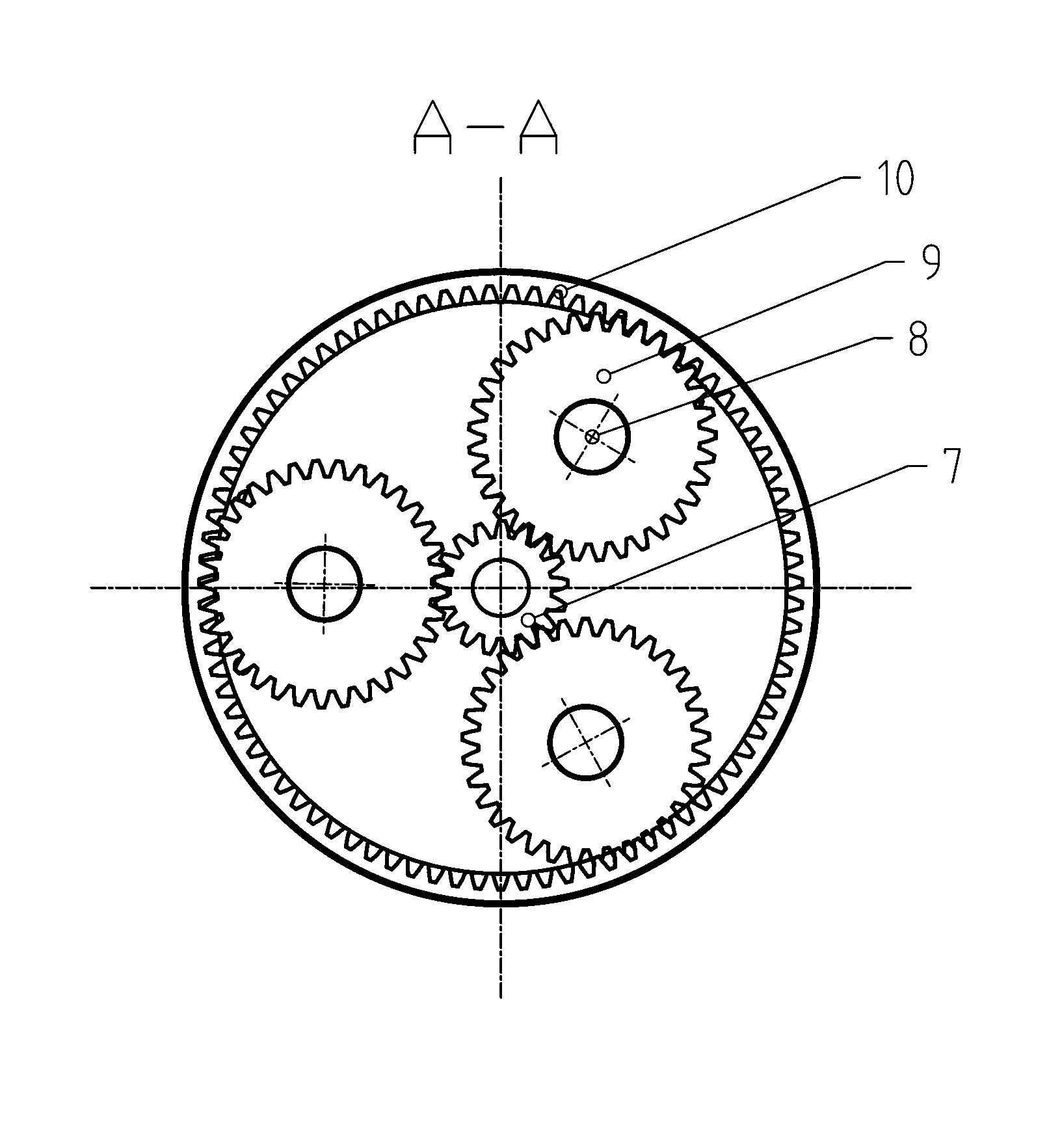

[0016] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-2 As shown, in order to show the main structure, the supports at both ends of the present invention are not drawn, but this does not affect the essence of the present invention. For clarity and conciseness of the view, parts such as bolts, bearings, sealing rings are not shown with serial numbers in the figure.

[0017] A lifting mechanism of an electric shovel, comprising a reel 1, a reel inner sleeve 2, an end support flange 3, a mechanical end face seal 4, a transmission side main shaft 5, a first-stage sealing end cover 6, and a first-stage sun gear 7 , first-stage planetary pin 8, first-stage planetary 9, first-stage ring gear 10, first-stage planetary carrier 11, second-stage planetary carrier 12, second-stage planetary pin 13, second First-stage inner ring gear 14, second-stage planetary gear 15, second-stage sun gear support 16, second-stage s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com