Novel flange connection type hub axle tube

A hub axle tube, connecting technology, applied in the directions of axles, wheels, transportation and packaging, can solve the problems of large equipment investment and labor, and achieve the effect of reducing costs, ensuring high precision and high performance requirements.

Inactive Publication Date: 2013-04-03

QINGTE GRP

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The hub shaft tube is an important part used in the three-section axle housing. Now the hub shaft tube is pressed into the axle housing to form the axle housing assembly. This method is labor-intensive and requires a special press to be purchased for press assembly, and the investment in equipment is large.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

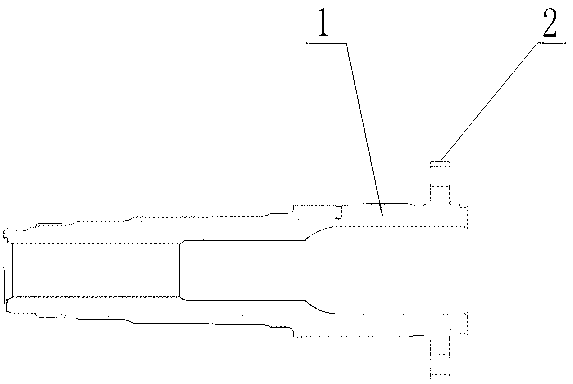

[0009] A new type of flange-connected hub shaft tube, including a hub shaft tube 1, the press-fit part at the end of the hub shaft tube 1 is canceled and changed to a flange structure 2, and the flange structure 2 is integrated with the hub shaft tube 1 set up. When in use, bolts connect the hub shaft tube to the axle housing, and at the same time, an O-ring seal groove is added at the end to prevent oil leakage.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a novel flange connection type hub axle tube, which comprises a hub axle tube (1). A flange plate structure (2) is arranged at the end part of the hub axle tube (1); and the flange plate structure (2) is integrally arranged with the hub axle tube (1). When in use, the hub axle tube is connected to an axle housing through bolts. According to the hub axle tube, the high precision and high performance requirements of the axle housing assembly can be effectively ensured; the hub axle tube is simple in structure and convenient to mount; the cost can be effectively reduced; and the purpose of reducing cost and increasing benefit is achieved.

Description

technical field [0001] The invention relates to a novel flange connection hub shaft tube. Background technique [0002] In the past two years, after the end of the country's macroeconomic policy of vigorously stimulating the economy, the development of infrastructure in various regions has been slow, the truck market has also shown a certain downturn, and the growth rate of major truck manufacturers has slowed down. Reducing costs and increasing efficiency has once again become a magic weapon for major manufacturers to win. The hub shaft tube is an important part used in the three-section axle housing. Now the hub shaft tube is pressed into the axle housing to form the axle housing assembly. This method is labor-intensive and requires a special press to be purchased for press assembly, and the investment in equipment is large. Therefore, there is an urgent need for a low-cost, easy-to-install, and simple-structure hub axle tube. Contents of the invention [0003] The tec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B60B35/00

Inventor 纪建奕权西坡纪国清

Owner QINGTE GRP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com