Automatic material taking apparatus

An automatic retrieving and automatic technology, which is applied in the field of automatic retrieving devices, can solve the problems of potential safety hazards, manipulators accidentally hitting operators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

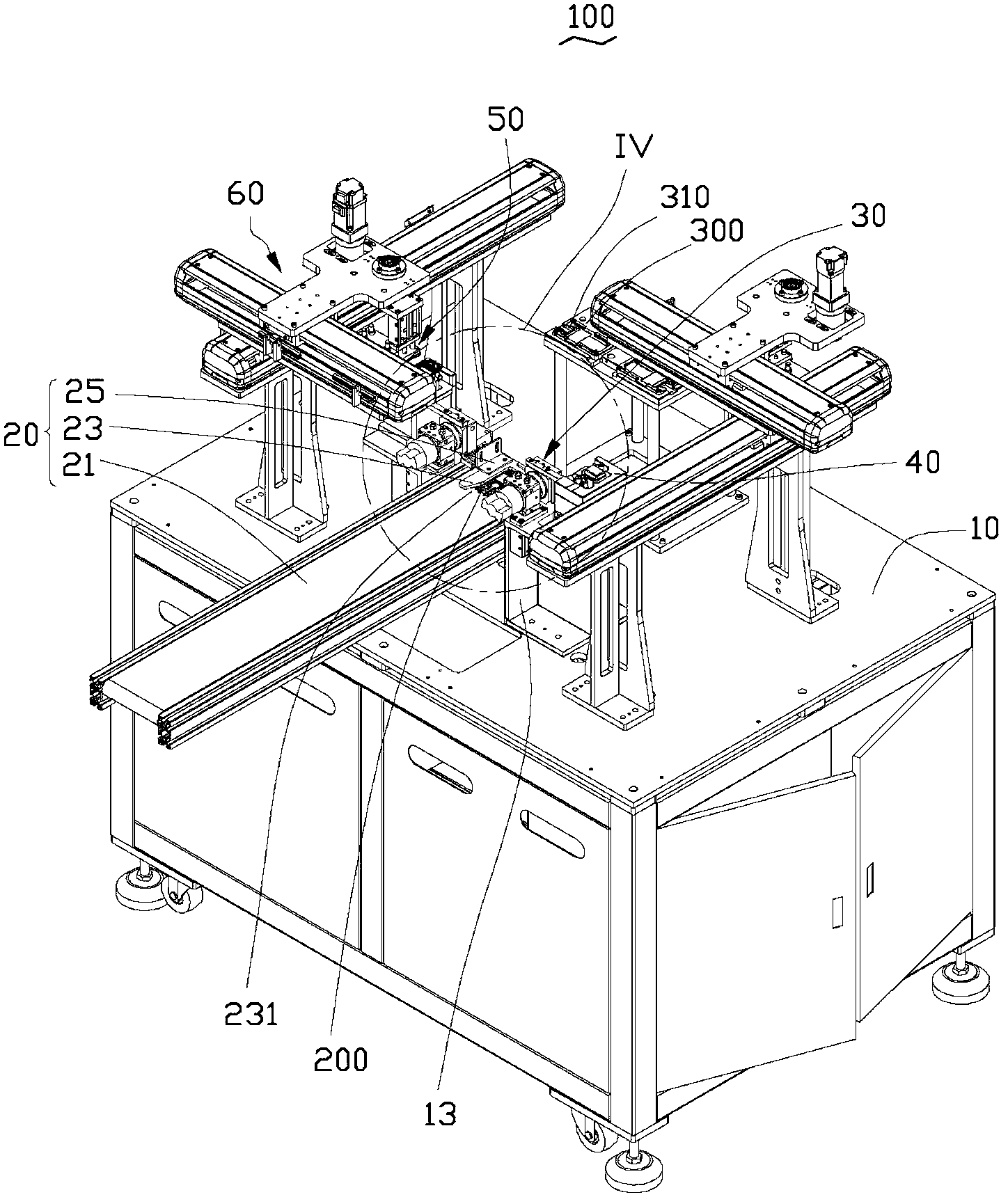

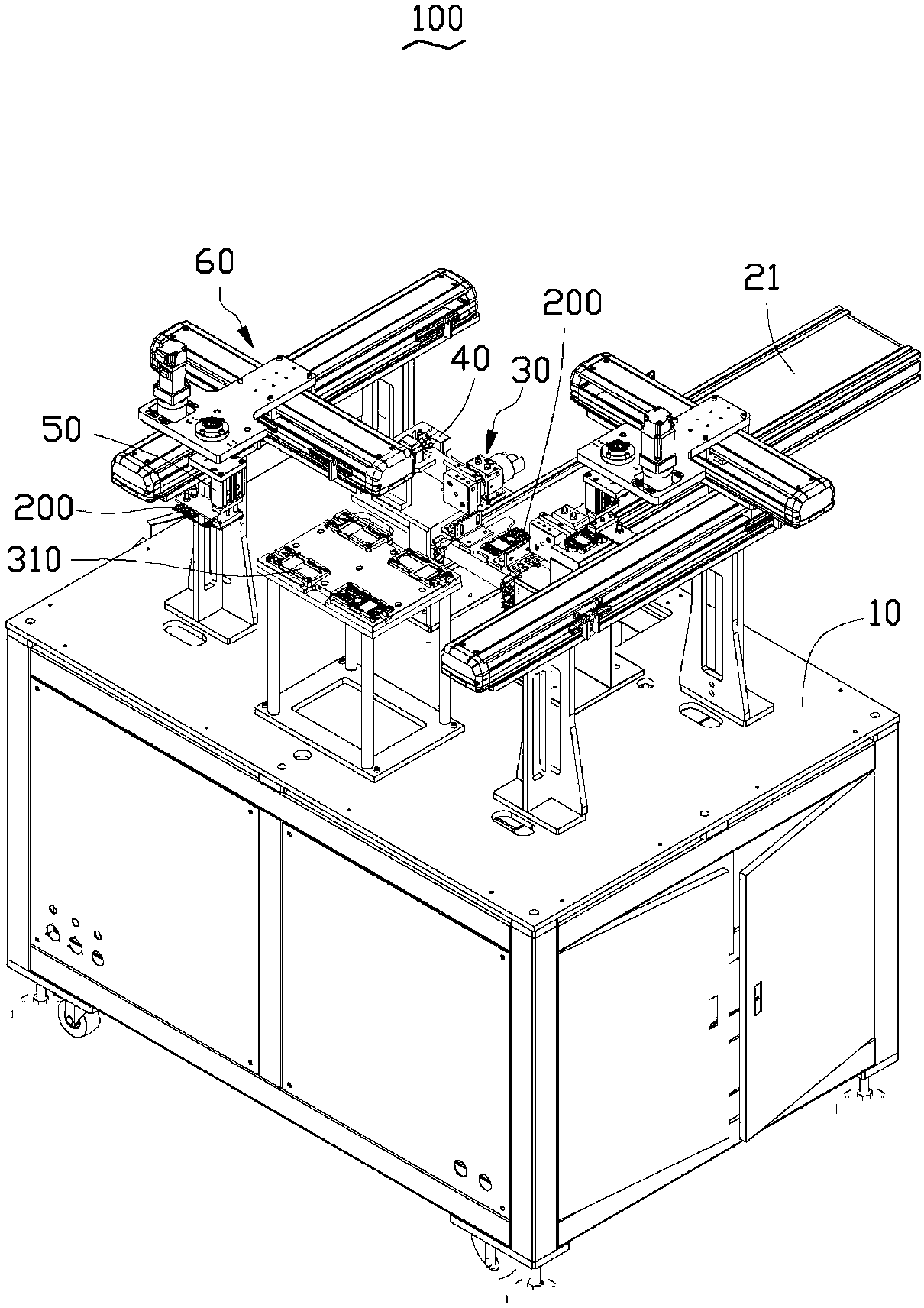

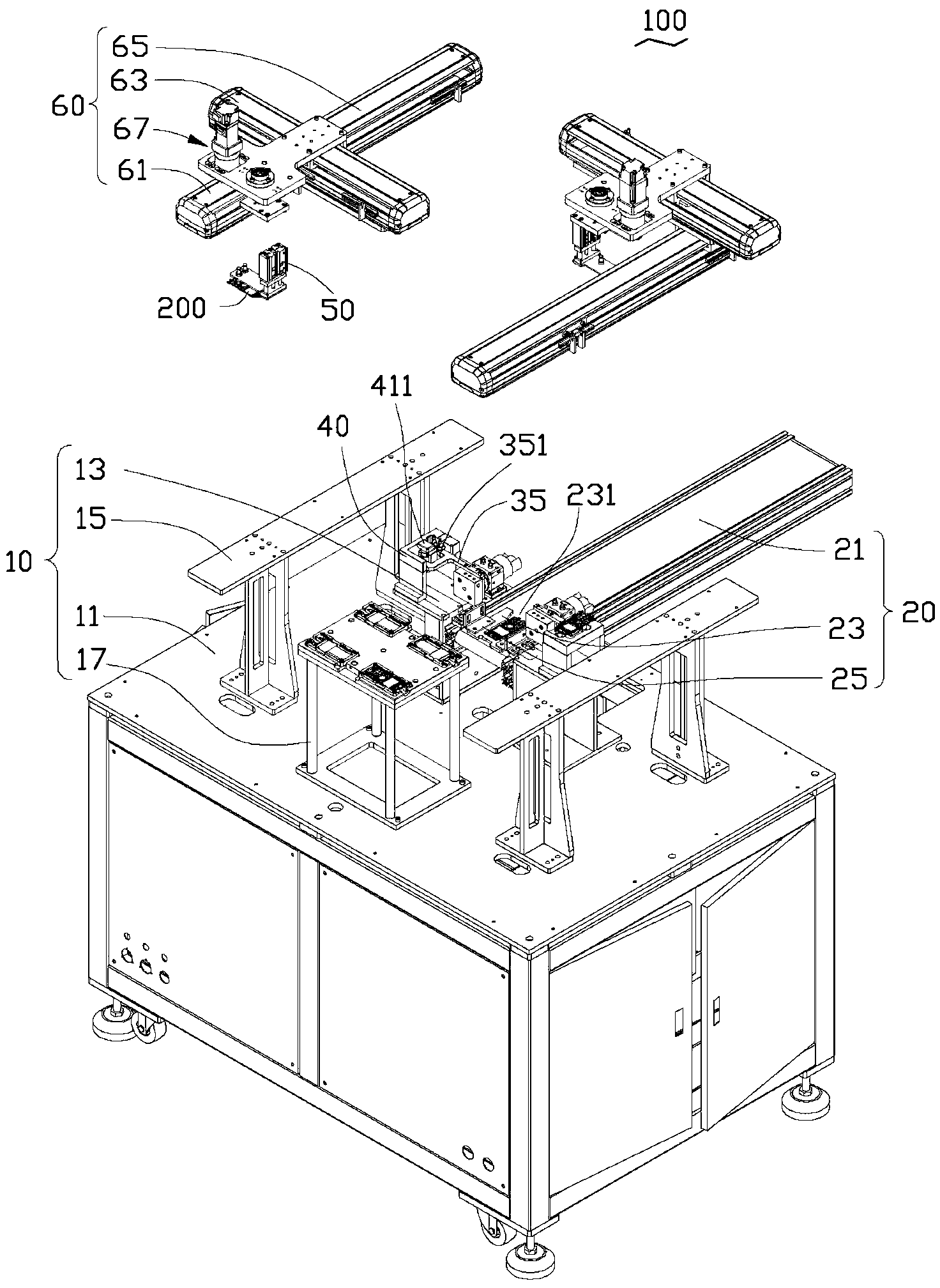

[0015] see figure 1 and figure 2 , the automatic pick-up device 100 according to the preferred embodiment of the present invention is used to automatically grab the workpiece 200 and position the workpiece 200 on the processing platform 300 . A plurality of processing positioning jigs 310 are fixedly fixed at intervals on the processing platform 300 for positioning the workpiece 200 grabbed by the automatic retrieving device 100 to facilitate processing of the workpiece 200 . The automatic retrieving device 100 includes an installation base 10 , a feeding mechanism 20 , an overturning mechanism 30 , a retrieving and positioning jig 40 , a grasping mechanism 50 and a conveying mechanism 60 . The feeding mechanism 20 transfers the workpiece 200 to the turning mechanism 30; the turning mechanism 30 grabs the workpiece 200 and places the workpiece 200 on the retrieving and positioning jig 40; The workpiece 200 is grabbed on the material positioning fixture 40;

[0016] see i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com