Stamping assembly capable of reducing stamping pressure

A technology of stamping pressure and assembly, which is applied in the field of bottle rough blank processing accessories, can solve the problems of controlling product weight, increasing punch pressure, disadvantage, etc., and achieves the effect of benefiting product weight, controlling product weight and reducing punch pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

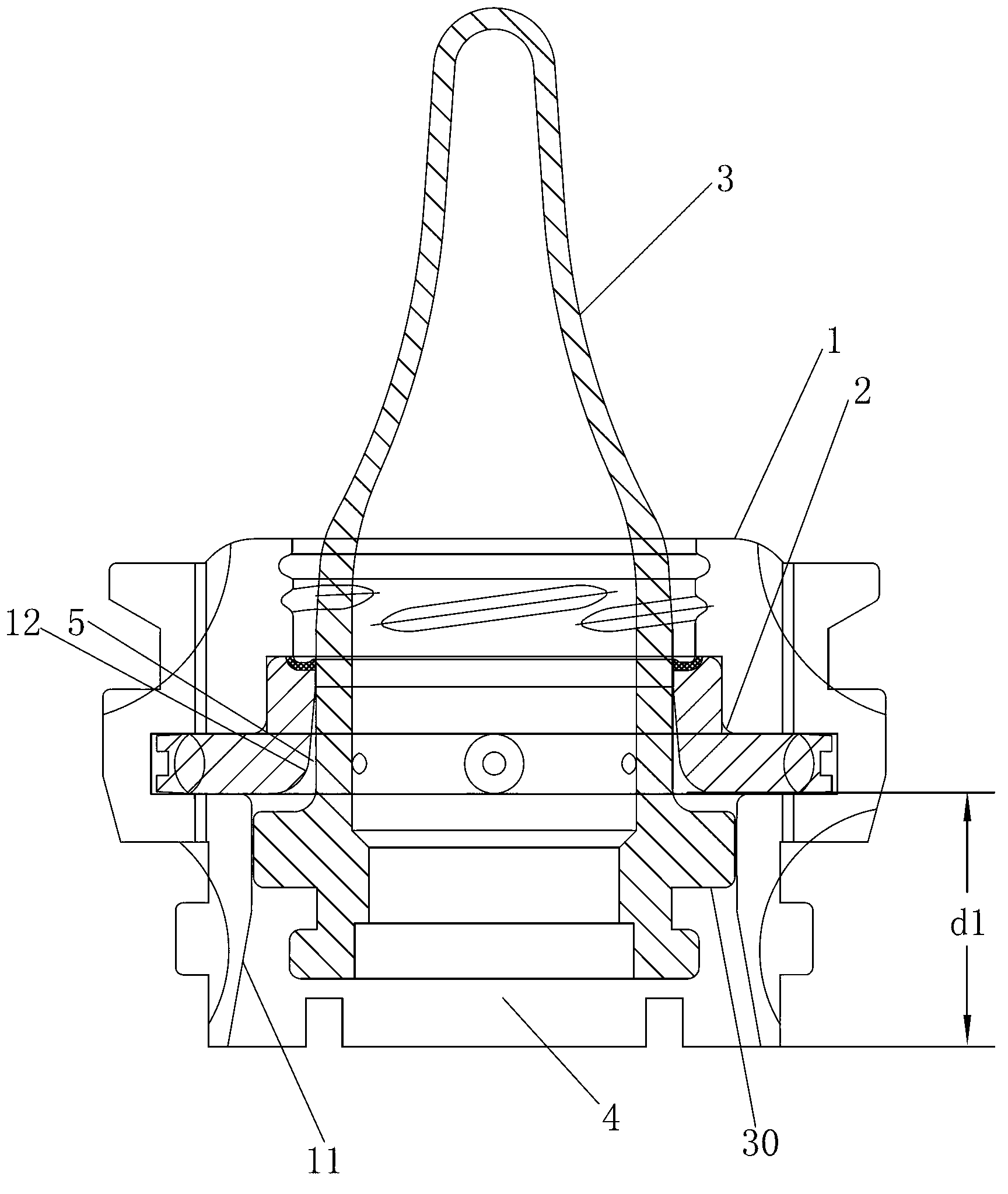

[0012] Embodiment: A stamping assembly that can reduce stamping pressure, such as figure 1 As shown, it includes the die 1, the mouth ring 2 and the punch 3, and the first through hole 4 and the second through hole 5 for the punch to move in and out are respectively provided in the die 1 and the mouth ring 2, and the mouth ring 2 is set In die 1. The punch 3 is sleeved in the first through hole 4 and the second through hole 5, and the head of the punch 3 is exposed outside the die 1. The convex ring 30 at the lower part of the punch 3 is against the mouth ring 2, and the convex ring 30 is the mouth Stopped by the ring 2, the distance d1 between the bottom end of the mouth ring 2 and the bottom end of the die 1 is 1.0 cm.

[0013] At the punch entrance 11 at the bottom of the die, the inner diameter of the first through hole 4 changes from large to small; at the punch entrance 12 at the bottom of the mouth ring, the inner diameter of the second through hole 5 changes from larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com