Gas distributor

A gas distributor and distributor technology, used in chemical instruments and methods, feeding devices, chemical/physical processes, etc., can solve the problem of poor gas phase mixing, affecting equipment operation and efficiency, and it is difficult for distributors to achieve uniform distribution of gas, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

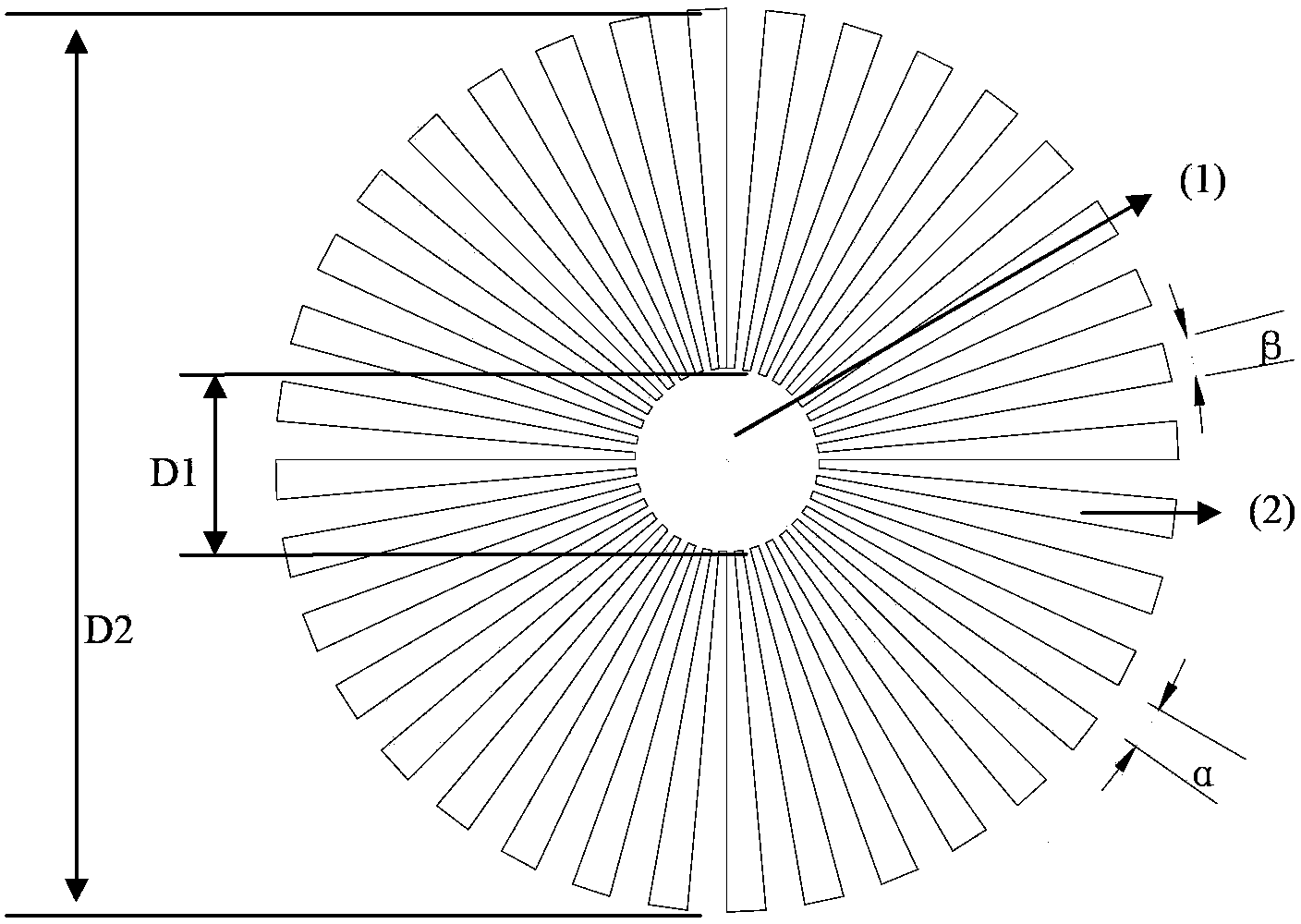

[0016] Example 1: The structure of a single distribution disk is as follows figure 1 As shown, it consists of a baffle and fan-shaped blades. The fan blades surround the baffle in an equidistant annular array. The baffle is a disc with a diameter of D1, which prevents the gas stream from penetrating the equipment for a short time and causing a short circuit. The size of D1 is the same as the inner diameter of the gas inlet pipe of DN600. The inner diameter of the main body of the equipment is 4m, and the outer diameter D2 of the fan-shaped blade is 3.2m. With the baffle as the center, the rotation interval angle α of two adjacent blades is 5°, and the included angle β of the blade itself is 5°. The single distribution plate is made of carbon steel, and the baffle and fan-shaped blades are cut from a single piece of steel plate and installed by installing a bracket at the bottom. Its installation position is set at half of the total height of the gas inlet section of the eq...

example 2

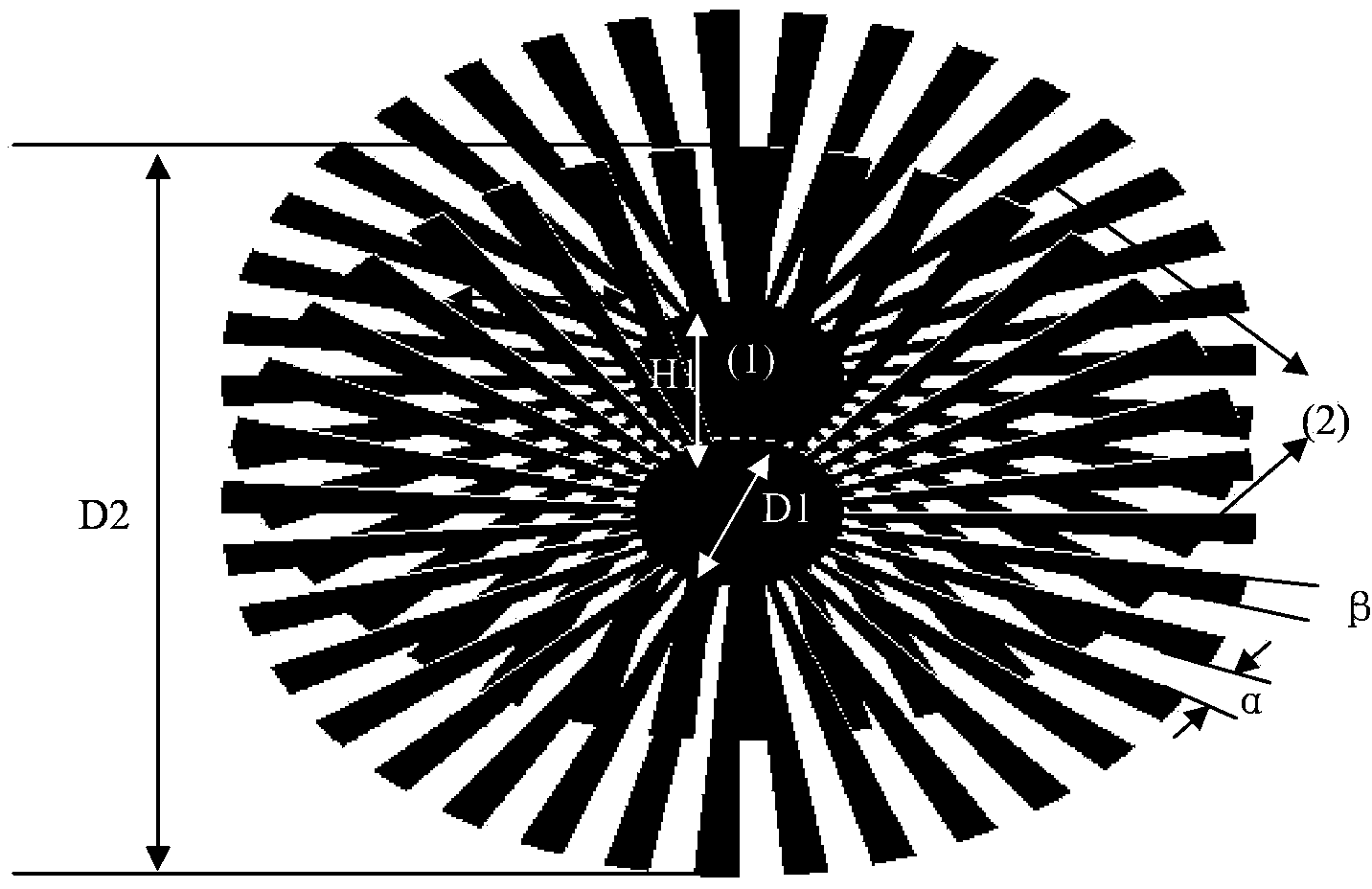

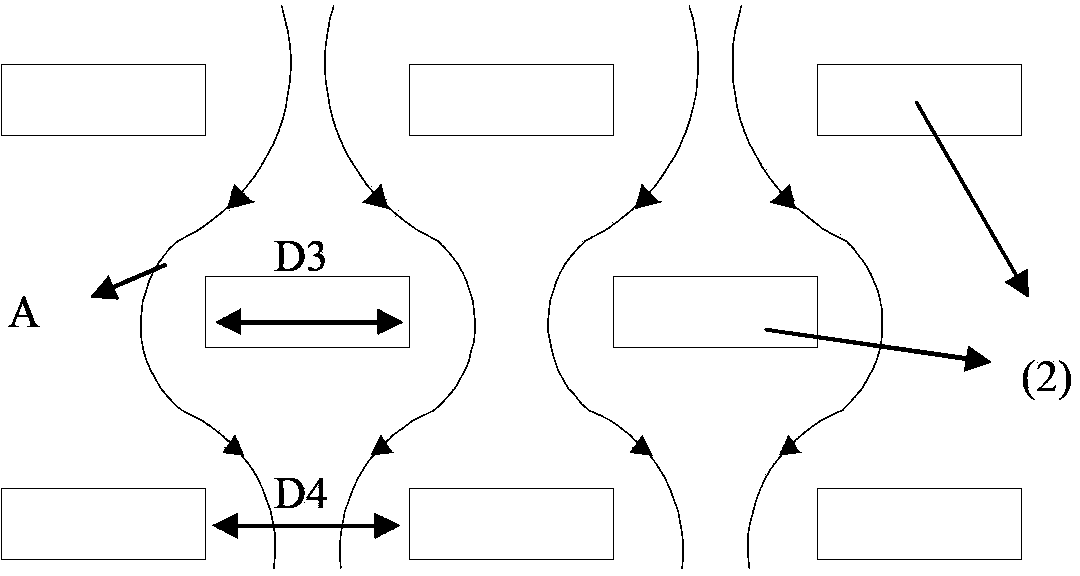

[0017] Example 2: figure 2 It is a schematic diagram of a two-pan gas distributor. For each distribution disc, the rotation interval angle of two adjacent blades is 4°, and the included angle of the blade itself is also 4°. The size of the baffle diameter D1 is the same as the inner diameter of the gas inlet pipe of DN800. The inner diameter of the main body of the equipment is 6m, and the outer diameter D2 of the fan-shaped blade is 5.4m. The forms of the two distribution discs are exactly the same, and the two distribution discs are fixed on a common support shaft, arranged in sequence on the support shaft, and their respective fan-shaped blades and gas channels are interlaced. The distance between the two distribution discs is set H1 to be 1 / 20 of the inner diameter of the inlet pipe. The material of the distributor parts is high-strength alloy steel, the baffle and the fan-shaped blades are fixedly connected by bolts, and the installation method is top hoisting. Where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com