Dies and crimping method

A technology of assembly and molding, applied in the direction of connections, electrical components, conductive connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

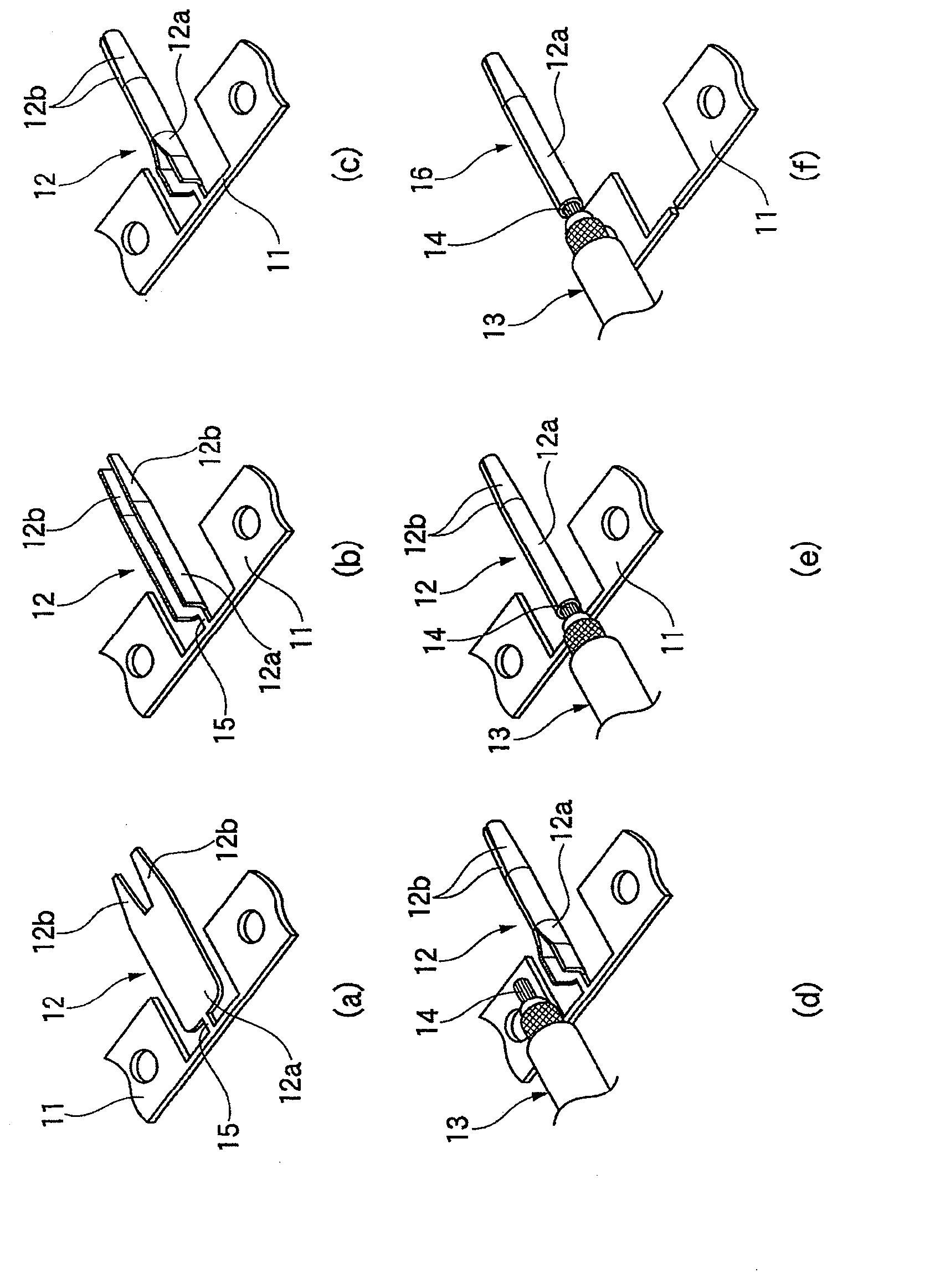

[0053] will be referred to below Figure 1 to Figure 5 (b) Describes the crimping method of the embodiment of the present invention.

[0054] figure 1 The chain terminal of the embodiment shown in includes: a carrier 11 and a flat plate-shaped terminal forming piece 12 continuously provided at a plurality of positions of the carrier 11 along its longitudinal direction. The terminal forming sheet 12 is formed into a terminal by pressing. The ends of the signal conductors 14 of the electric wires 13 are accommodated in each terminal forming sheet 12 folded during the pressing work. The terminal forming pieces 12 are successively provided at a plurality of positions of the carrier 11 along the longitudinal direction thereof via respective carrier bridges 15 .

[0055] The signal conductor 14 is formed by bundling a plurality of core wires 14a. The ends of the signal conductors 14 are placed in the center of each terminal forming piece 12 . The right and left ends of the ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com