Resistor calibration circuit

A technology of calibrating circuit and current calibration, applied in the directions of amplifying control device circuits, electrical components, adjusting electrical variables, etc., can solve the problems of low efficiency and low adjustment accuracy, and achieve the effect of ensuring accuracy and improving adjustment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

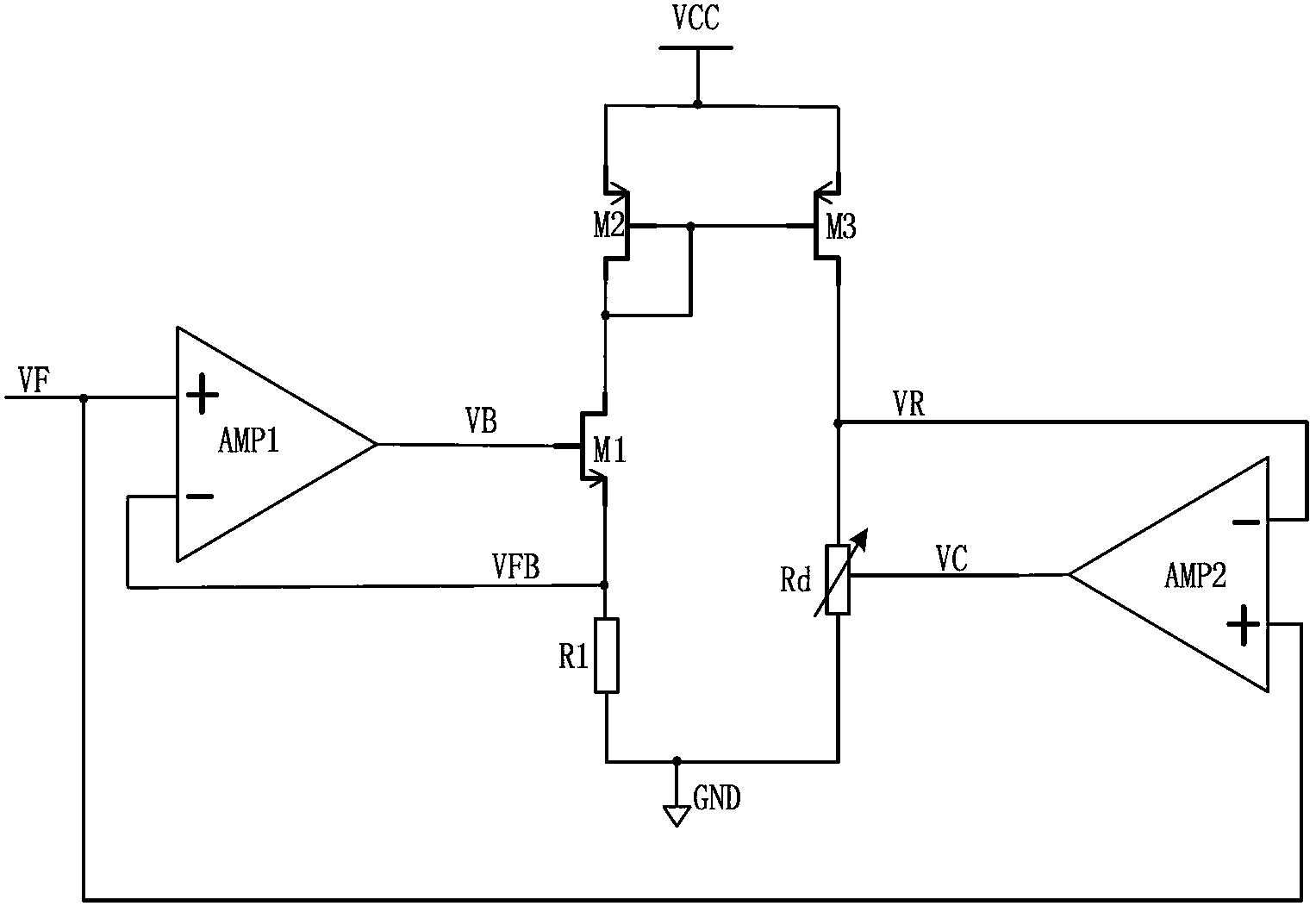

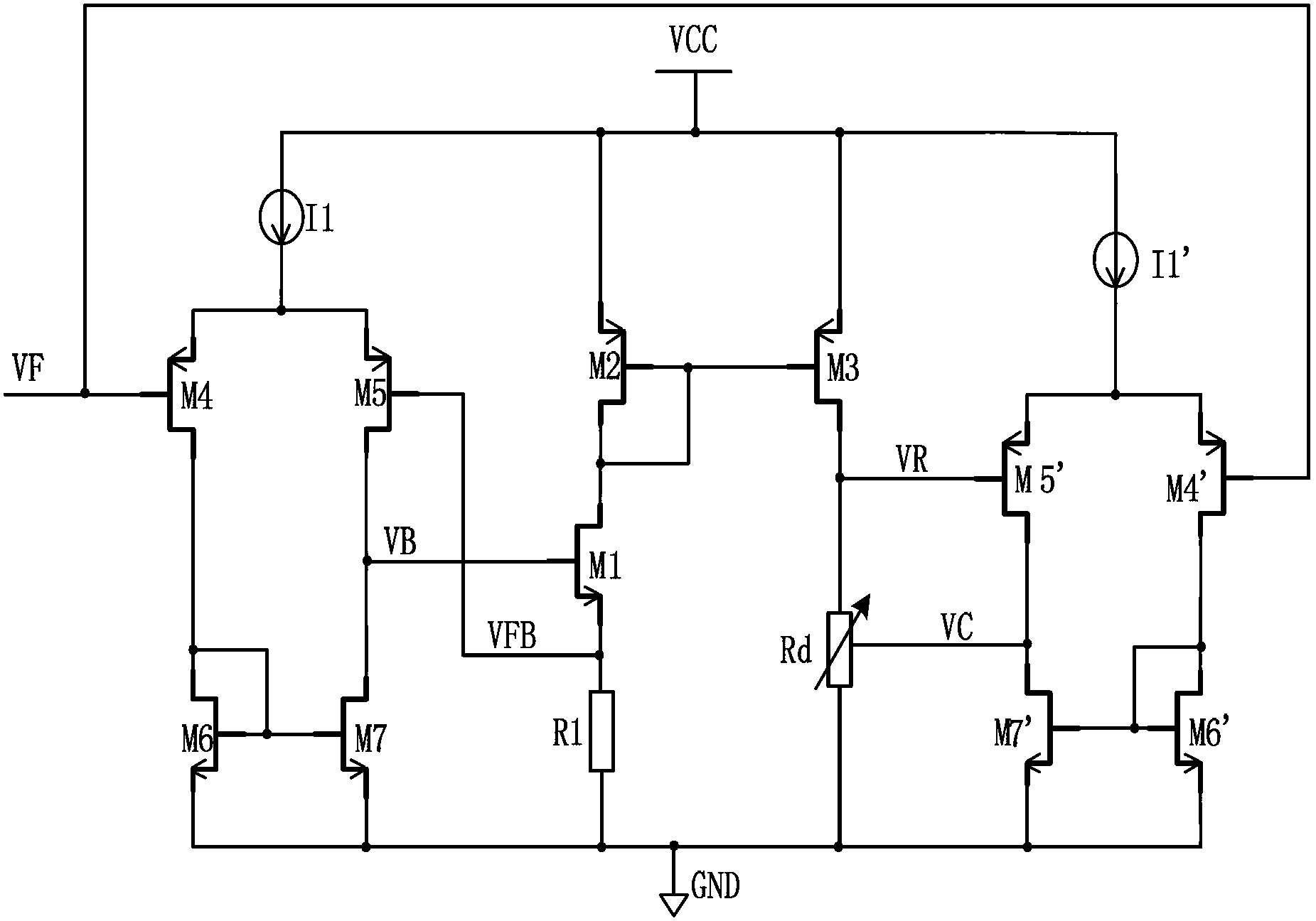

[0018] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a resistance calibration circuit, which can automatically adjust the resistance value of the voltage-controlled resistor to be calibrated, and has high adjustment accuracy and high efficiency.

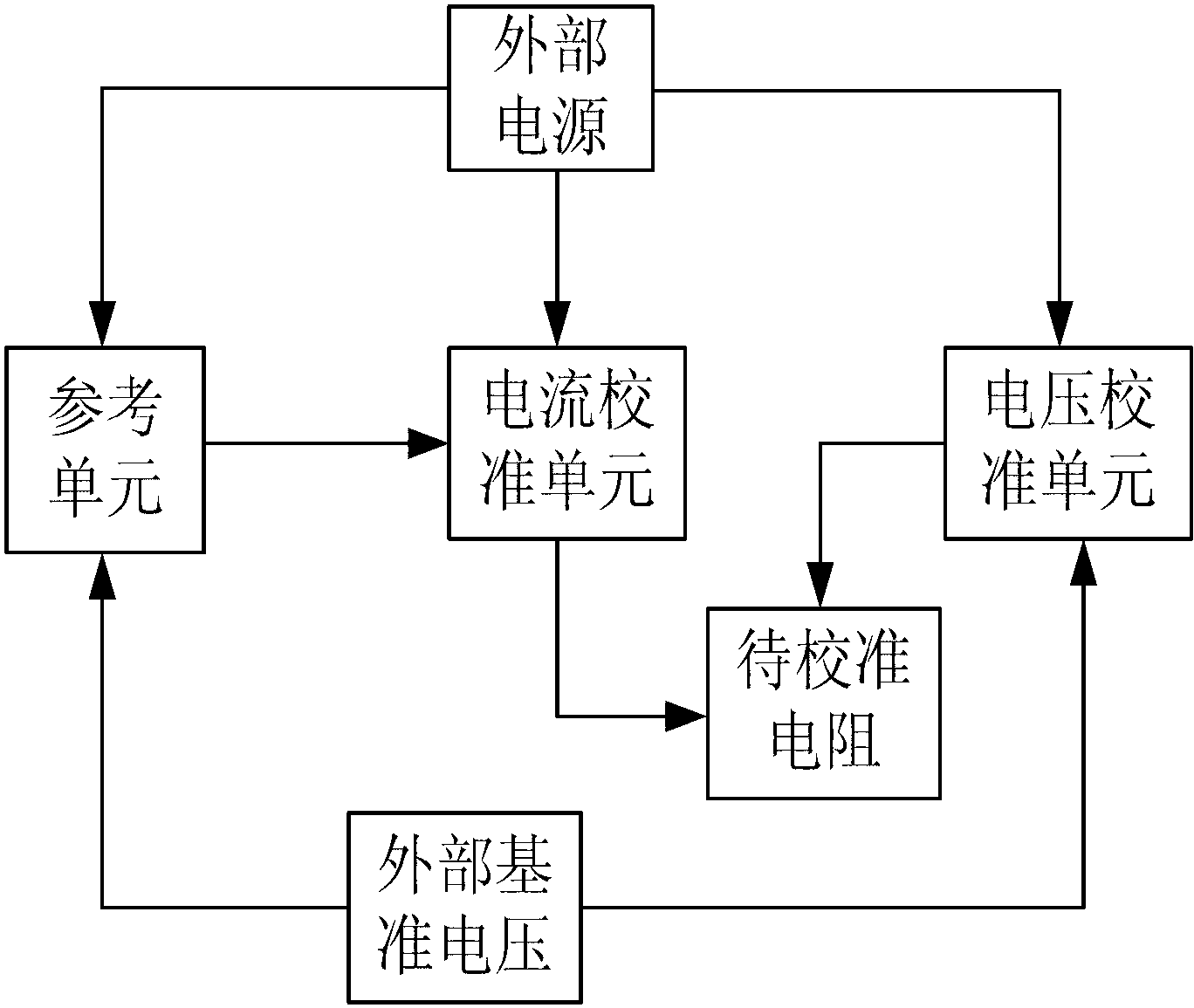

[0019] Please refer to figure 1 , figure 1 It is a structural block diagram of the resistance calibration circuit of the present invention. As shown in the figure, the resistance calibration circuit of the present invention includes an external power supply, a reference unit, a current calibration unit, and a voltage calibration unit respectively connected to the external power supply, and an external reference voltage connected to the reference unit and the voltage calibration unit respectively, respectively. The voltage-controlled resistance to be calibrated connected to the cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com