Part shape difference detection method based on multi-scale mesh vertex average gradient

A technology of average slope and grid vertices, which is applied in the field of difference detection between part shape groups based on the average slope of multi-scale grid vertices, can solve problems such as limitations, detection limitations, and single scale, and achieve high reliability and high detection results. The effects of robustness and accuracy, improving reliability and resistance to random noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

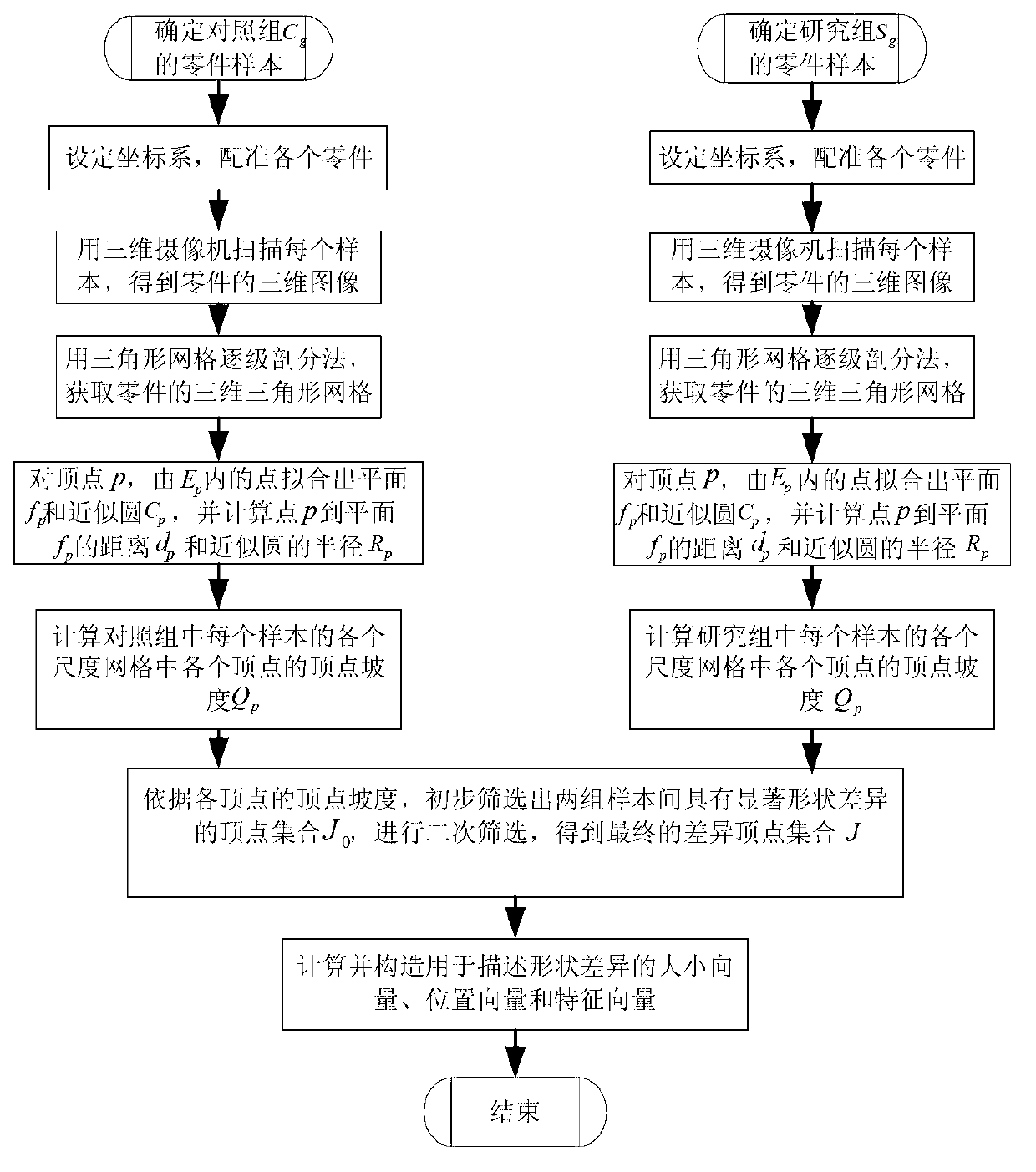

[0021] refer to figure 1 , the implementation steps of the present invention are as follows:

[0022] In the first step, all the part samples are divided into two groups, which are called the control group C g and research group S g .

[0023] In this step, all the part samples are divided according to their different attributes, such as processing from two different machines, or from the same machine but using different constituent materials, according to actual needs. Control group C g and research group S g .

[0024] When dividing sample groups, the number of samples in the two groups should be equal or close to ensure the accuracy and reliability of the results obtained by statistical analysis.

[0025] In the second step, according to the geometric characteristics, the control group C g and research group S g All parts are registered in the same Cartesian coordinate system.

[0026] In this step, all samples, including samples of the control group and samples of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com