BOP (blowout preventer) storage and transportation device for deep sea float type drilling well

A floating and drilling technology, which is applied in earthwork drilling, wellbore/well components, sealing/packing, etc., can solve problems such as rollover and damage of guide rails, and achieve floor space saving, low cost and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

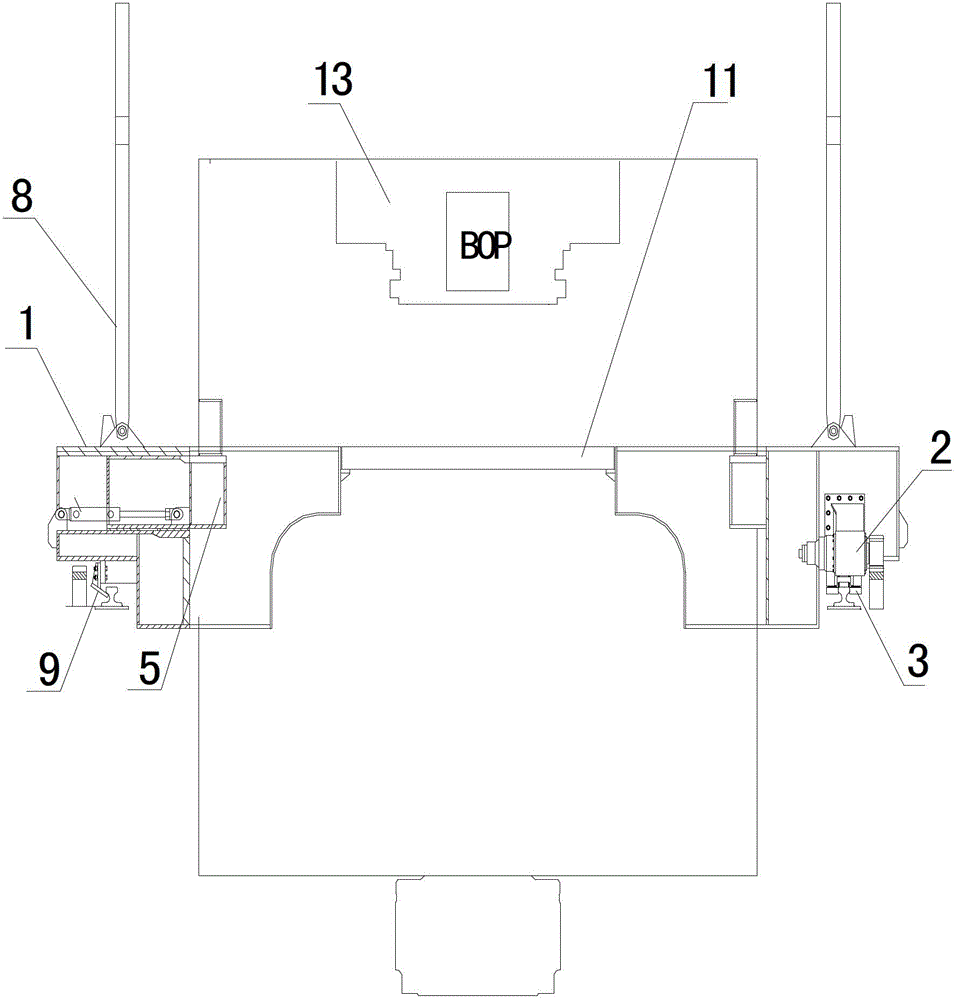

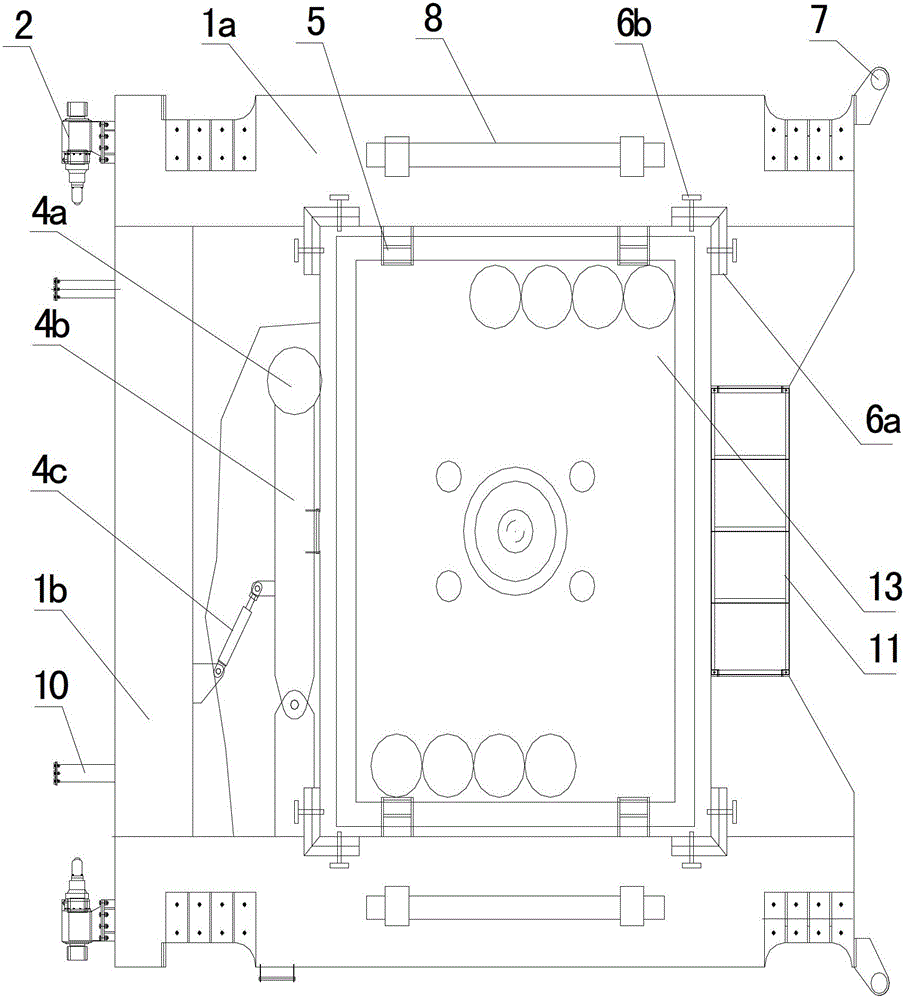

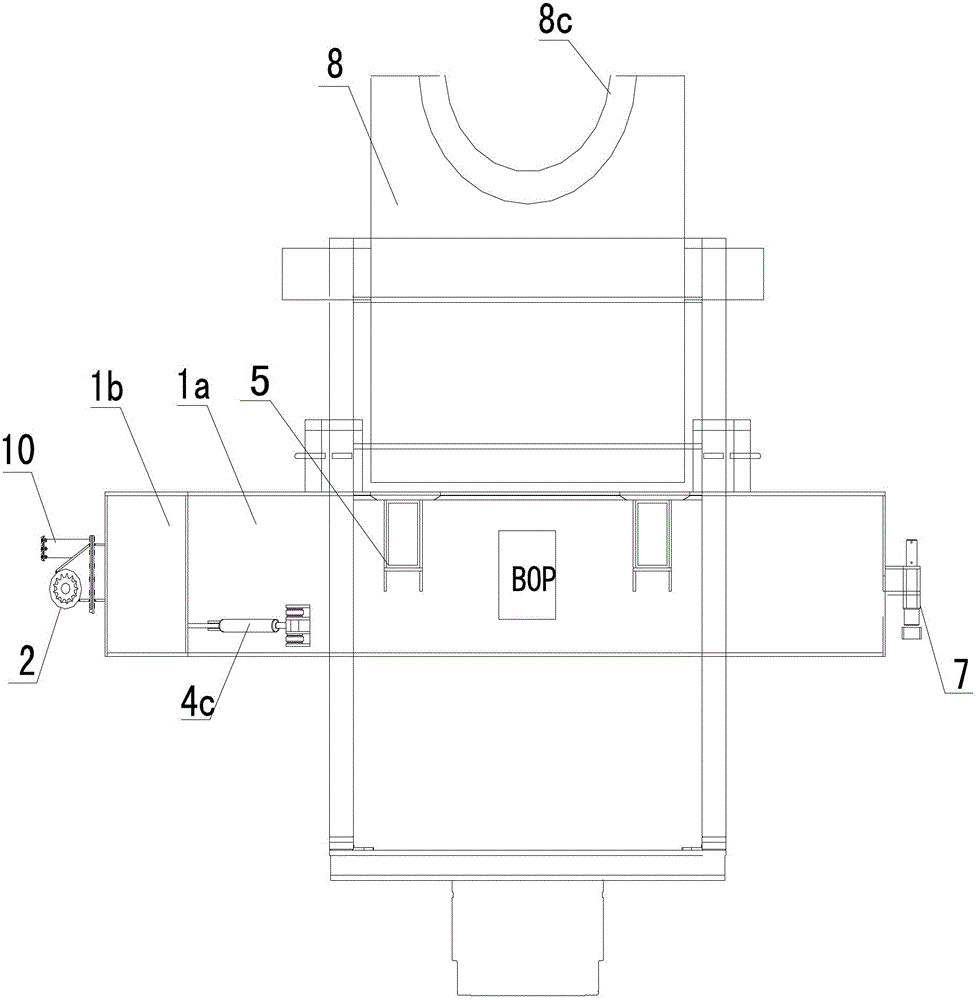

[0077] Such as Figure 1 to Figure 17 As shown, the deep sea floating drilling BOP storage and transportation device of the present invention includes a base body 1, the base body 1 is welded by two side box girders 1a and a rear end box girder 1b, and the whole is a "C" shaped cross section, or " A tensile body with a “door” cross-section. After welding, the middle part of the substrate 1 forms a cavity that can accommodate the BOP frame 13. The BOP is loaded in the BOP frame 13 and can be hoisted into the cavity from above the substrate 1 to realize loading. and storage. The two side box girders 1a and one rear box girder 1b are not completely closed in cross section, forming a structure with an open front end, which can be reserved as a channel for the riser 12 to move out of the base 1 from the side.

[0078] The rear-end box beam 1b is provided with a mobile walking platform 11, which can be used as a temporary passage. After the operator goes up to the mobile walking pl...

Embodiment 2

[0096] This embodiment is an embodiment of the deep-sea floating drilling BOP storage and transportation device under storage conditions.

[0097] In the storage working condition, the deep-sea floating drilling BOP storage and transportation device needs to be parked stably on the guide rail 3a on the hull, and the storage working condition usually occurs during drilling waiting and towing.

[0098] Such as Figure 1 to Figure 3 As shown, in the storage working condition, the working status of the main components on the deep sea floating drilling BOP storage and transportation device is as follows: the hydraulic lock pin 7 is inserted into the preset pin hole on the hull, the support device 5 is retracted inside the base body 1, The clamping device 6 is in a retracted state, that is, the adjusting screw on the clamping device 6 and the operating platform 8 are in a non-working state in the vertical direction.

[0099] By fixing the hydraulic lock pin 7 in the preset pin hole...

Embodiment 3

[0107] This embodiment is an embodiment of the deep-sea floating drilling BOP storage and transportation device under pressure test conditions. The pressure test must be carried out before lowering the BOP to ensure that the BOP can work safely.

[0108] Such as Figure 7 and Figure 8 As shown, before the pressure test condition, the working status of the main components on the deep-sea floating drilling BOP storage and transportation device is as follows: the hydraulic lock pin 7 is inserted into the preset pin hole on the hull, the support device 5 is in the extended state, And hold up the BOP frame 13, the clamping device 6 is in the extended state to clamp the BOP frame 13, and the operating platform 8 is in the vertical non-working state.

[0109] The operation method of carrying out the pressure test using the BOP storage and transportation device for deep-sea floating drilling in this embodiment is as follows:

[0110] a. Adjust the adjusting screw 6b of the clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com