Hydraulic pump rotational speed measurement device

A speed measurement and hydraulic pump technology, which is applied to devices using electric/magnetic methods, etc., can solve the problem of no hydraulic pump speed measurement device, etc., and achieve the effect of simple structure and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

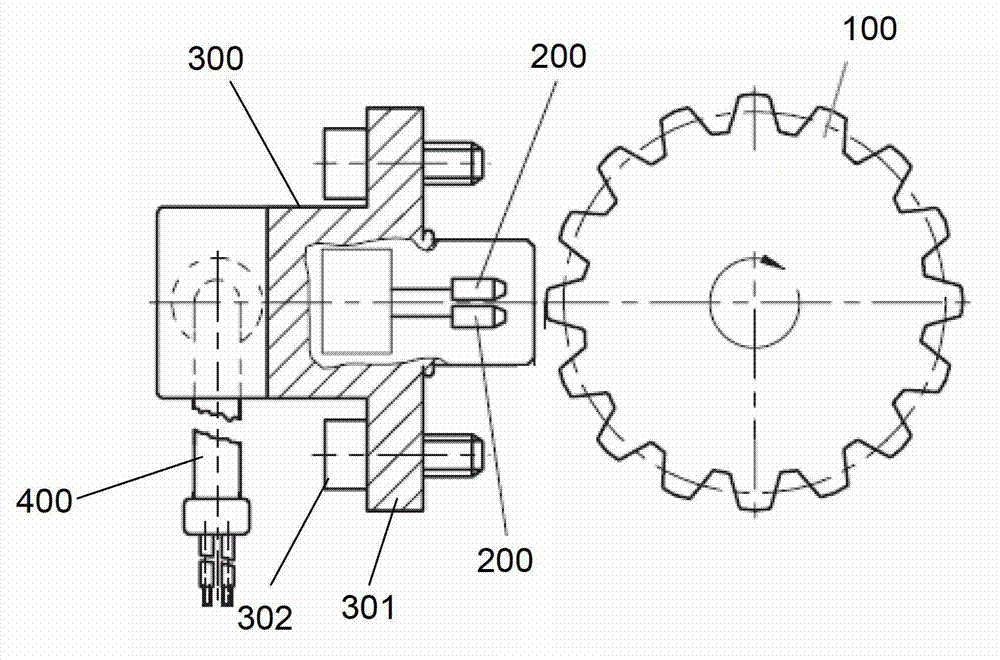

[0015] like figure 1 As shown, the hydraulic pump rotational speed measuring device of the present invention includes a magnetic gear 100 , a Hall effect element 200 , a housing 300 and a cable 400 .

[0016] Wherein, the Hall effect element 200 is located beside the magnetic gear 100 and aligned with the magnetic gear 100 along the radial direction of the gear. One end of the casing 300 has an opening covering the Hall effect element 200 , the opening faces the magnetic gear 100 , and the cable 400 passes through the rear end (the other end) of the casing. Both sides of the housing 300 have fixing ears 301 , and fixing bolts 302 are arranged on the fixing ears 301 .

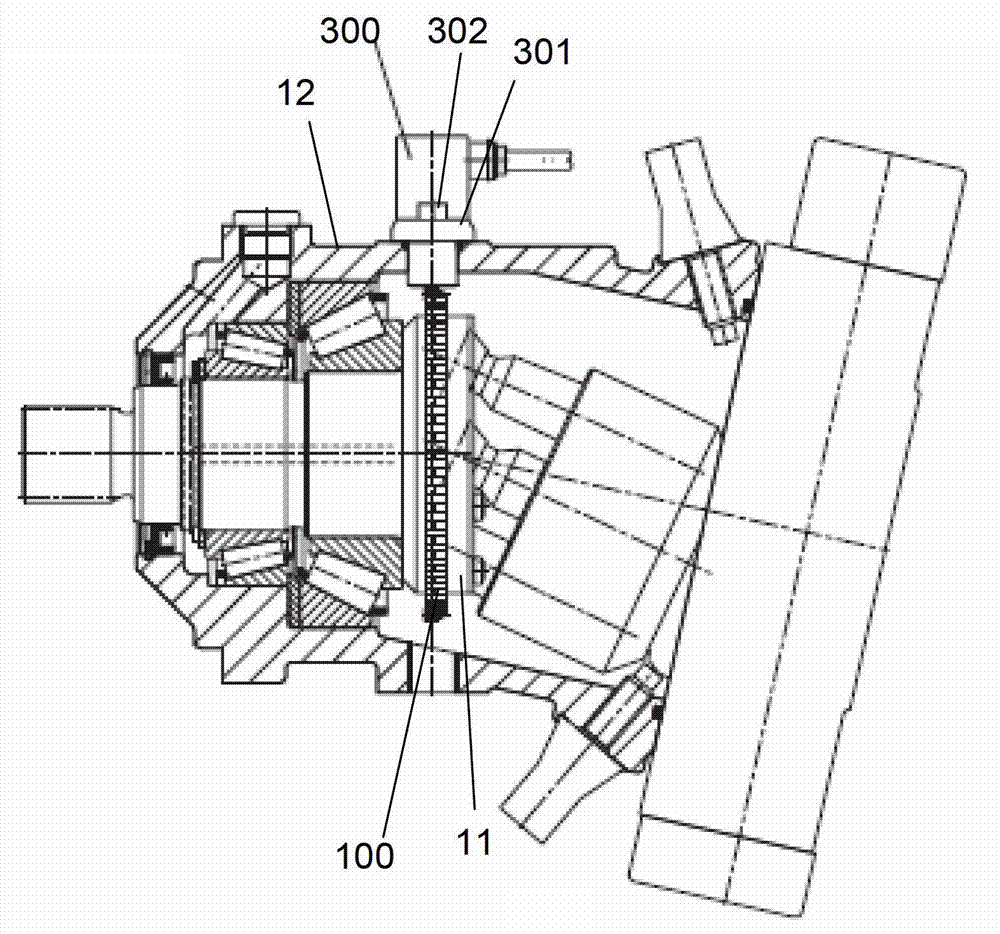

[0017] In order to be conveniently installed on the rotary body inside the hydraulic pump, combined with figure 2 As shown, the magnetic gear 100 is preferably a ring gear.

[0018] like figure 2 As shown, a kind of installation mode of the present invention in hydraulic pump is as follows:

[0019] The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com