Method for measurement of silicon-based graphics chip surface benzotriazole concentration through infrared reflection technique

A technology of benzotriazole and infrared reflection, which is applied in measuring devices, color/spectral characteristic measurement, material analysis through optical means, etc. It can solve the problems of inability to detect BTA concentration on the surface of large-sized wafers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

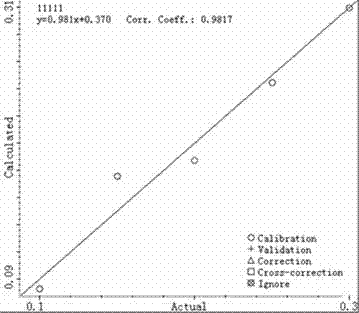

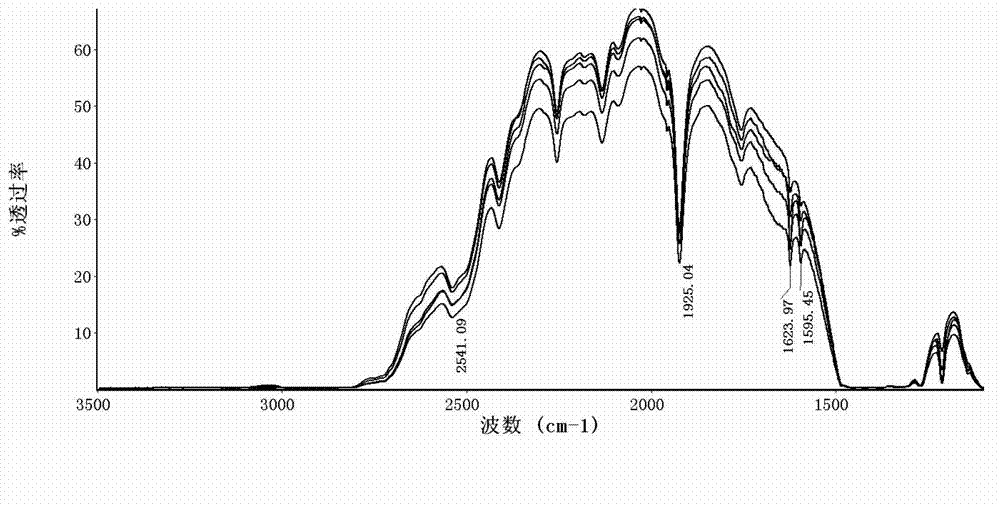

[0019] Firstly, prepare the sample before testing: place the benzotriazole in a vacuum or a blast oven to dry to remove the free water contained in the sample. Using absolute ethanol as a solvent, benzotriazoles were prepared into 0.1 mol / L, 0.15 mol / L, 0.2 mol / L, 0.25 mol / L, 0.3 mol / L BTA, respectively. Use the microsampler to get the prepared BTA of the same volume and add it dropwise on the silicon-based graphic chip of twelve inches according to the position of the five-point method, such as figure 1 shown. Leave the silicon-based graphic sheet dripped with BTA for half an hour to make it diffuse evenly. Place the static silicon-based graphic sheet on the map300 sample stage, and use Nicolet 6700 Fourier transform infrared spectrometer to measure its infrared spectrum (see figure 2 ), use TQ Analyst (infrared quantitative analysis) to build a model curve, the steps are as follows: 1. Open TQ Analyst (infrared quantitative analysis) software, select Description (descript...

Embodiment 2

[0022] Firstly, prepare the sample before testing: place the benzotriazole in a vacuum or a blast oven to dry to remove the free water contained in the sample. Using absolute ethanol as a solvent, the benzotriazole was formulated into 0.15 mol / L, 0.2 mol / L, 0.25 mol / L, 0.3 mol / L, 0.35 mol / L BTA, respectively. Use the microsampler to get the prepared BTA of the same volume and add it dropwise on the silicon-based graphic chip of twelve inches according to the position of the five-point method, such as figure 1 shown. Leave the silicon-based graphic sheet dripped with BTA for half an hour to make it diffuse evenly. Place the silicon-based graphic sheet after standing on the map300 sample stage, use Nicolet 6700 Fourier transform infrared spectrometer to measure its infrared spectrum, use TQ Analyst (infrared quantitative analysis) to establish a model curve, the steps are as in Example 1; after polishing Place the sample on the MAP300 sample stage, open the OMNIC software, mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com