Start separation device for engine ignition

A separation device and engine technology, applied in the direction of automatic clutches, clutches, mechanical equipment, etc., can solve the problems of restricting factory production efficiency, long auxiliary time, cumbersome test procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

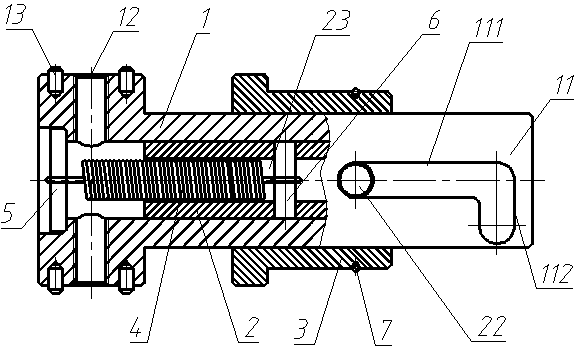

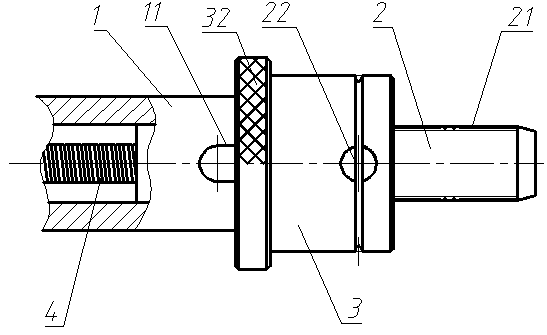

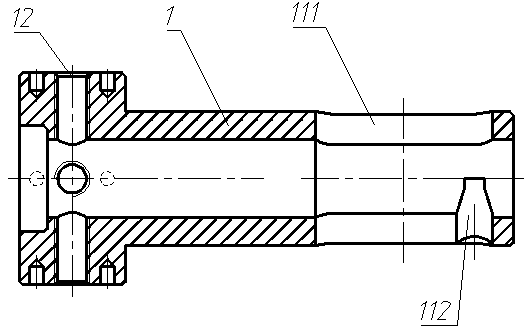

[0023] An embodiment of the start-up separation device for engine ignition of the present invention is as follows: Figure 1~Figure 8 As shown, it mainly includes a cylindrical transmission sleeve 1 as a transmission guide, a spline shaft 2 as a sliding butt joint, a sliding sleeve 3, a tension spring 4 and a retaining spring 7. The starting separation device for engine ignition adopts a frequency conversion motor as the engine ignition driving device, and the output shaft of the frequency conversion motor is connected with a coupling. Wherein, four threaded connection holes 12 are evenly distributed on the circumferential surface of the rear of the transmission sleeve 1 , and the torque transmission between the coupling and the transmission sleeve 1 is realized through bolts. There are also four positioning pins 13 on the circumferential surface to achieve precise positioning of the transmission sleeve 1 and the coupling.

[0024] The front part of the spline shaft 2 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com