Replaceable staking insert assembly and corresponding method

A technology of pile fixing and assembly, applied in the direction of pump components, engine components, non-variable pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present application will now be described more fully hereinafter with reference to the accompanying drawings, in which several embodiments of the application are shown. Like numbers refer to like elements in all figures.

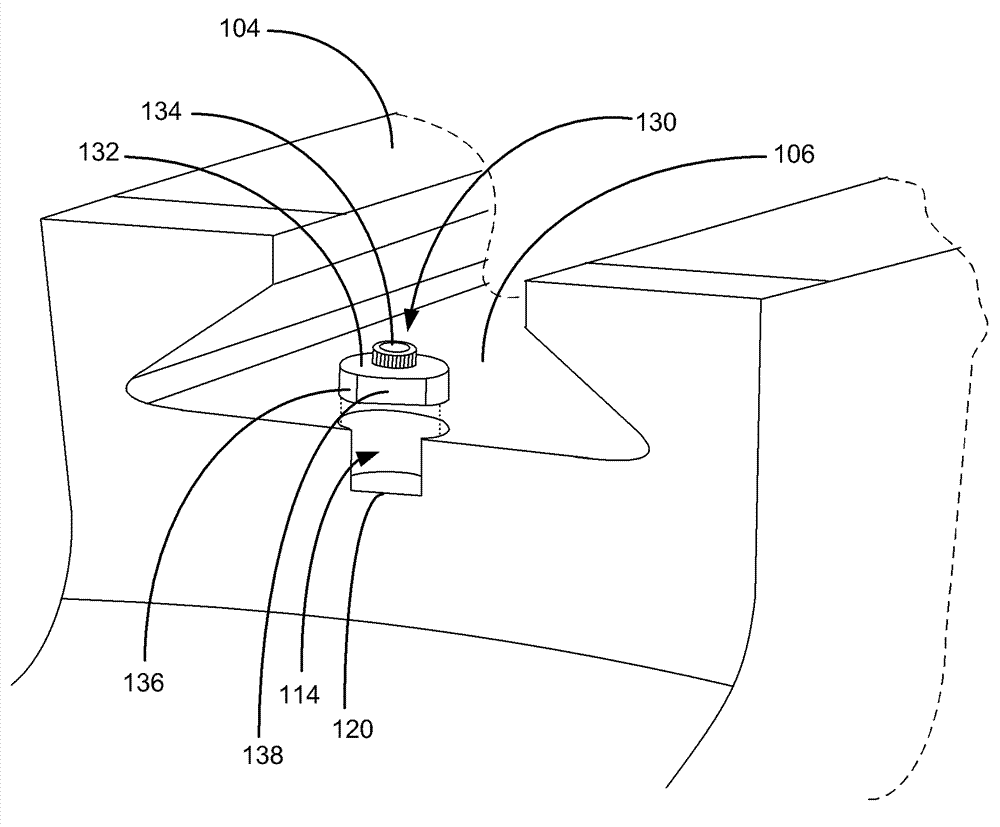

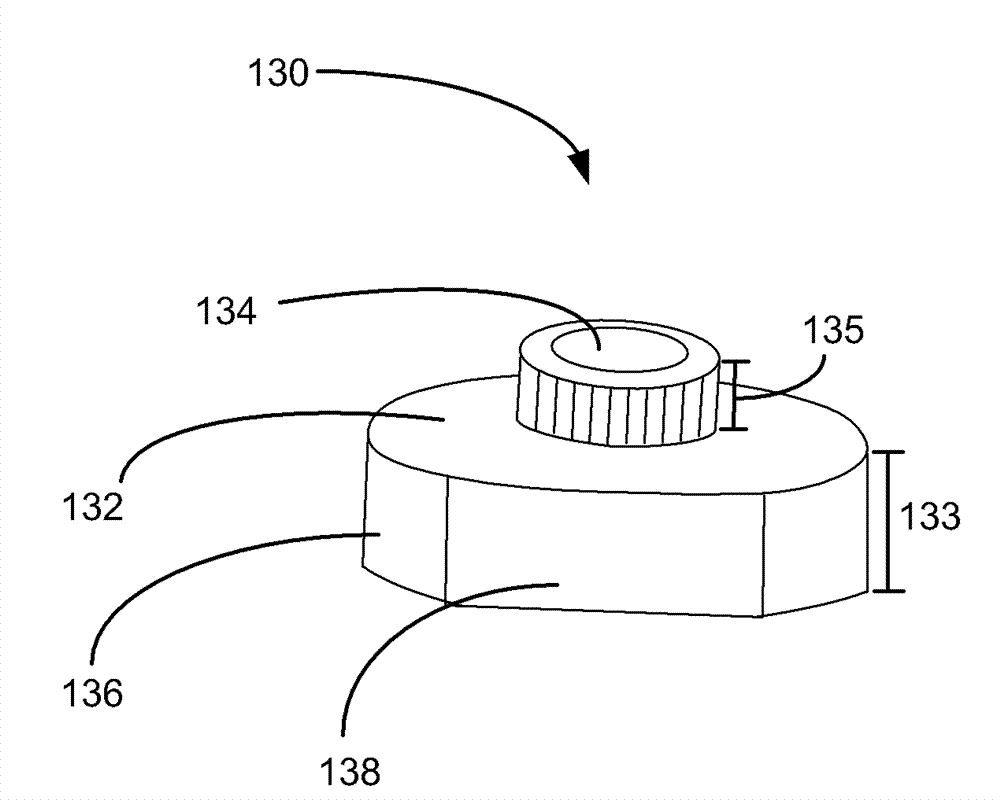

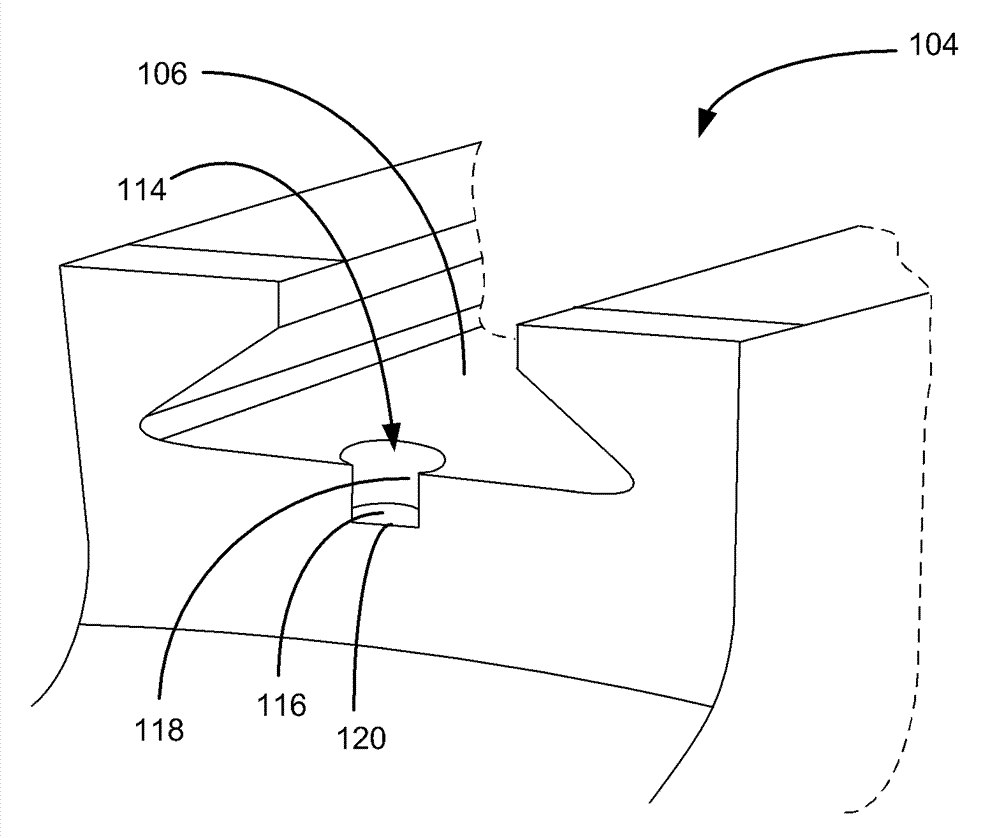

[0044] In one aspect, a rotor assembly is provided. Figure 1A and 1B Shown separately are rotor blades 102 and rotor 104, which are components of the rotor assembly. The rotor 104 may include at least one axial slot 106 positioned around the rim of the rotor 104 . Axial notch 106 may be of any shape known in the art. In certain embodiments, the axial notch 106 has a dovetail shape. The axial notch 106 may include a first staking notch 114 positioned therein. In some embodiments, the first staking recess includes a base and at least one sidewall. In one embodiment, a first staking notch 114 is positioned at one end of the axial notch 106 and has a base 116 and a recessed sidewall 118 defining an axial opening 120 . However, other shapes of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com