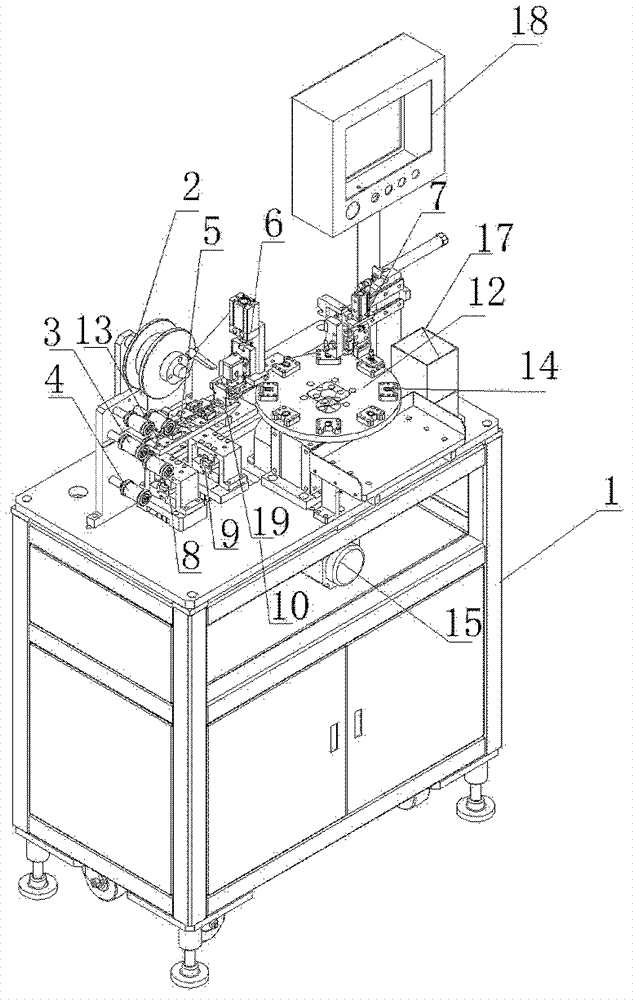

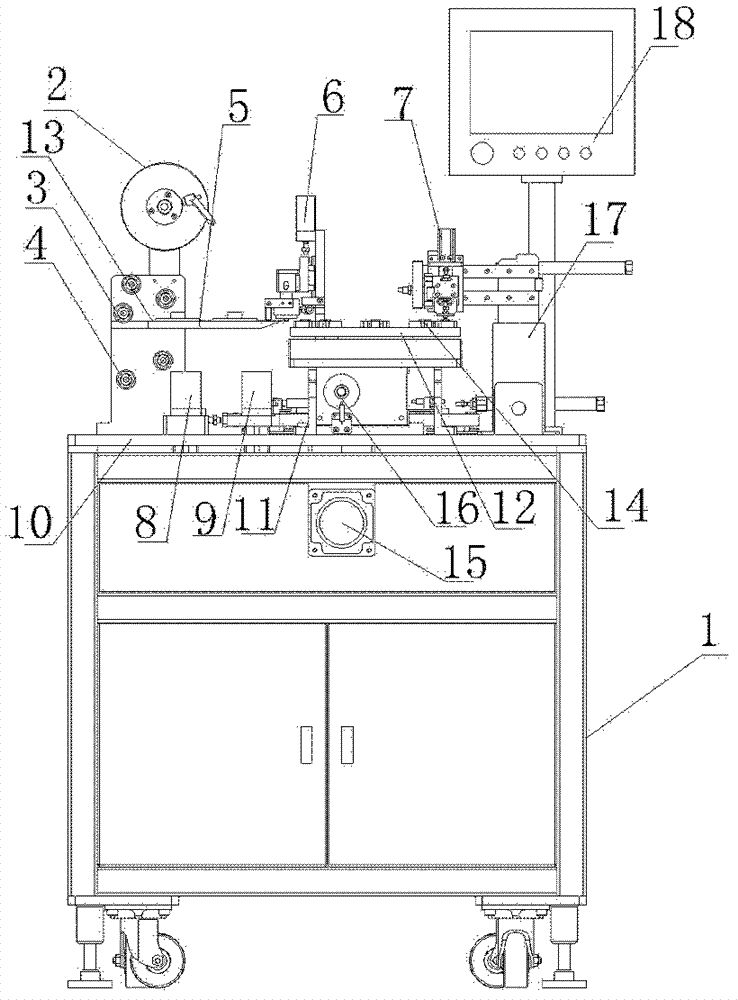

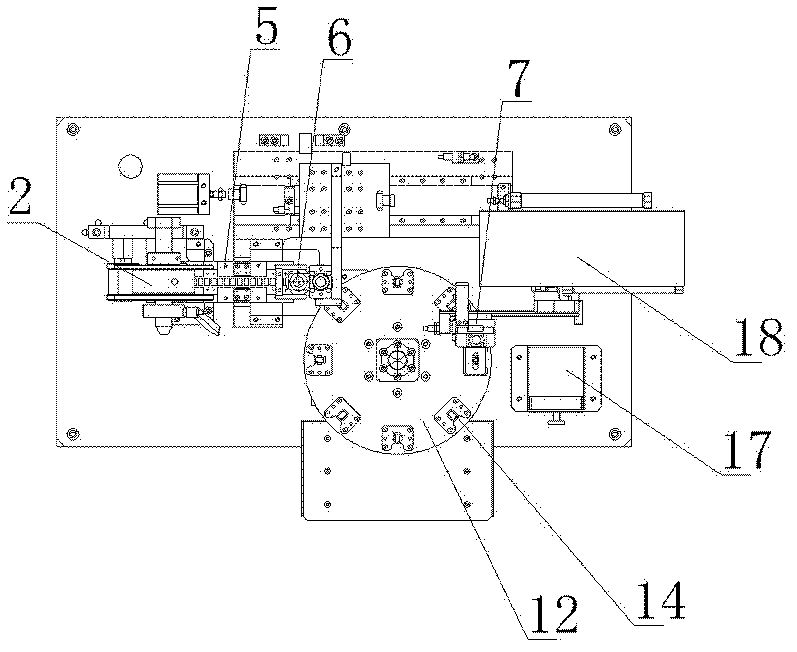

Full-automatic mylar adhering equipment

A fully automatic and equipment technology, applied in the direction of packaging automatic control, packaging, packaging protection, etc., can solve the problems of slow sticking Mylar, low production efficiency, large labor consumption, etc., to ensure quality, high work efficiency, and manpower saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] Embodiment: A kind of fully automatic mylar sticking equipment, comprises frame 1, material tray 2, first, second guide wheel 3,4, feeding board 5, first, second grasping device 6,7, first, Two fixing fixtures 8,9, the first and second fixing frames 10 and 11, the material setting plate 12 and the controller are based on the actual use direction, and are used for winding the material tray 2 and the first and second guide wheels of the Mylar strip Can be rotated and positioned on the frame 1 respectively, the feeding plate 5 is fixed on the frame 1, the first fixed frame 10 can be positioned on the frame 1 along the linear reciprocating movement direction of the material belt, and the second fixed frame 11 can be positioned along the The linear reciprocating motion of the material strip movement direction is positioned on the first fixed frame 10, and the first grabbing device 6 is longitudinally capable of reciprocating and fixed on the second fixed frame 11. The first g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com