Mechanical full-automatic floating garbage cleaning ship structure

A fully automatic, drifting ship technology, applied in the field of environmental protection engineering ships, can solve problems such as affecting water quality, increasing labor costs, inconvenient garbage unloading, etc., to facilitate repair and maintenance, improve production efficiency, and reduce labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

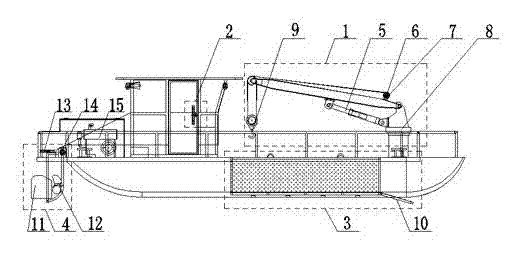

[0012] As shown in the drawings, when the mechanical fully automatic drift cleaning ship is working, open the frame door 10 of the collection frame 3, start the power supply of the diesel engine 15, and push the ship to sail forward so as to collect the floating garbage at the front end of the ship into the collection frame 3, After the collection frame 3 is full, close the frame door 10. Drive the ship back to the shore or dock, and then use the hydraulic crane 1 to unload the garbage in the collection frame 3 to the shore or dock. So far, the work of collecting, storing, transporting and unloading floating garbage on the water surface is completed.

[0013] Start the diesel engine 15, drive the pulley 14 to run by the belt, and provide the power of the propeller 12. In addition, by operating the throttle handle of the diesel engine and the reversing handle of the marine gearbox, the acceleration, deceleration, forward and backward of the ship can be realized. In addition, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com