Method of manufacturing wind energy facility rotor blade section with carbon fibre reinforced main belt

A technology for wind turbines and manufacturing methods, applied in the direction of final product manufacturing, sustainable manufacturing/processing, household appliances, etc., which can solve problems such as complex processes and difficult bonding of main beam covers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

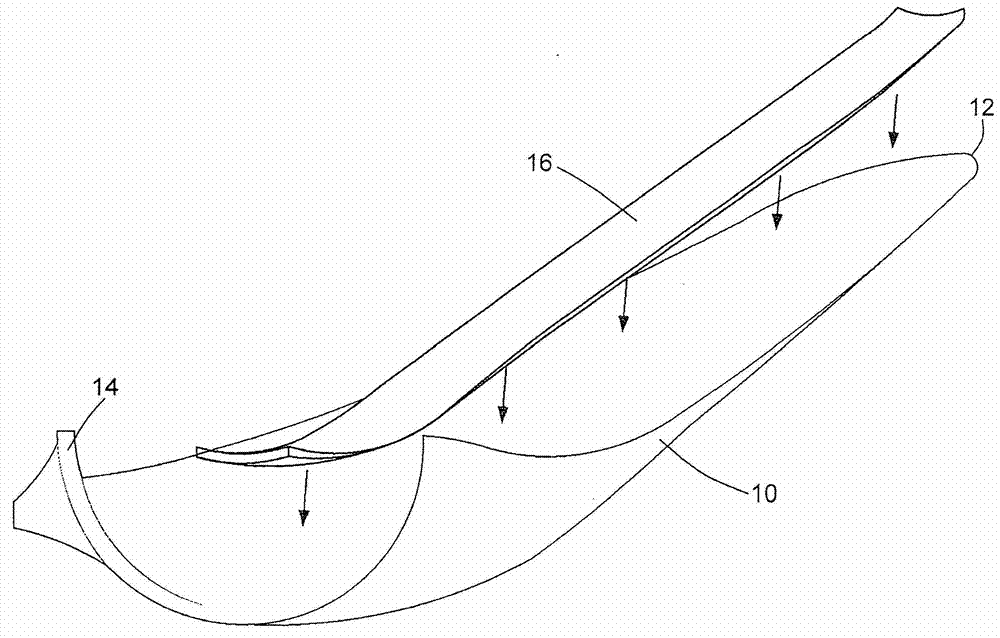

[0057] exist figure 1 In , a half-shell mold 10 can be seen having an end 12 at the tip of the blade and an end 14 at the root of the blade. The cross-section of the end 14 of the half-shell mold 10 at the blade root forms a semicircle. The overall length of the half-shell mold 10 is, for example, 40 m or more, 50 m or more or even 60 m or more. In these wind turbine rotor blades, for reasons of strength and weight, it is often justified to use carbon fiber reinforced main spar caps.

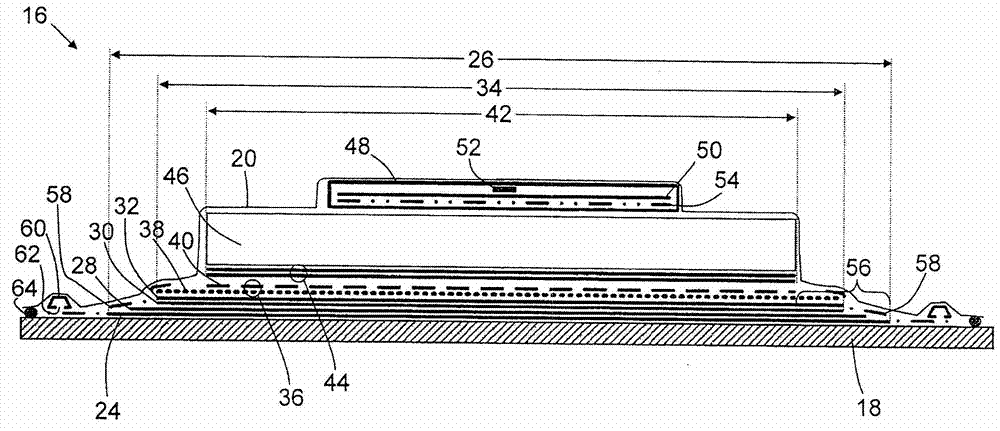

[0058] This figure illustrates how a wind turbine rotor blade part 16 manufactured according to the method of the invention is placed in the half-shell mold 10 . The wind turbine rotor blade part 16 extends approximately over the entire length of the half shell mold 10 , but has a smaller width, measured in the depth direction of the outer contour. Along its leading and trailing edges extending in the longitudinal direction, the wind turbine rotor blade part 16 has a figure 1 Laminar connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com