Manufacturing method of stator

A manufacturing method and stator technology, applied in the manufacture of motor generators, stator/rotor bodies, electrical components, etc., can solve problems such as inconvenient operation, long working hours, and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The primary purpose of the present invention is to provide a new stator manufacturing method, which can also be said to be a method for providing a protective layer on the stator assembly. The plan it adopts is:

[0018] A method for manufacturing a stator, comprising the following steps:

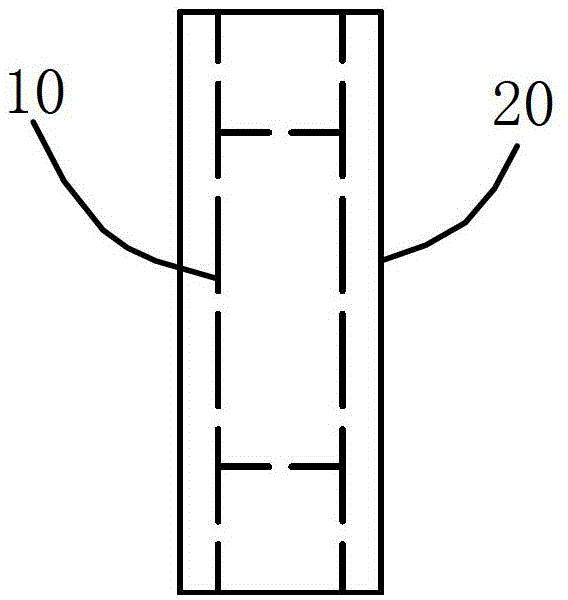

[0019] S1: winding the enameled wire onto the stator core, and then setting lead wires and / or circuit boards on the winding formed by winding the enameled wire, and fixing it with insulating tape to obtain a stator assembly;

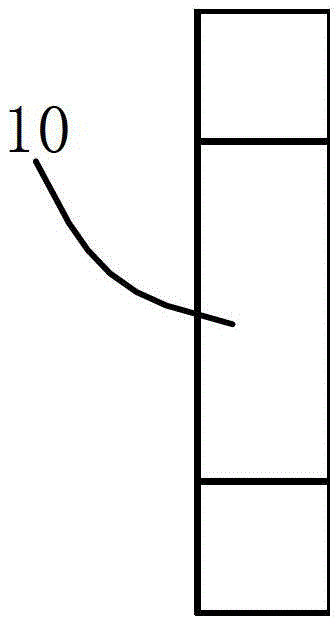

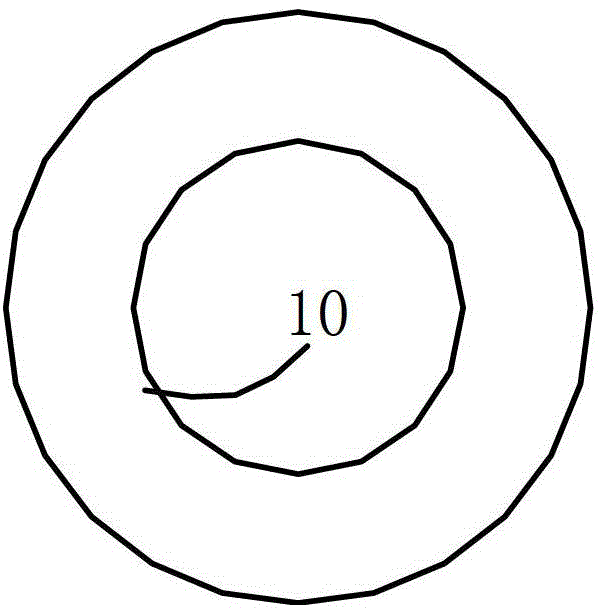

[0020] S2: Wind the plastic film 20 on the outer peripheral surface of the stator assembly 10 and make the plastic film 20 extend to the two outer ends of the stator assembly 10 respectively, and then heat the plastic film 20 with a heating device so that the plastic film 20 is plastically deformed to form a package wrapped around the stator An annular plastic groove 20' on the outer surface of the component 10;

[0021] S3: Put the stator assembly 10 provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com