Two-degree-of-freedom leveling device

A technology of leveling device and degree of freedom, applied in the direction of program-controlled manipulators, manufacturing tools, manipulators, etc., can solve the problems of large volume, large space occupation, slow working speed, etc., to reduce the volume of equipment, reduce the activity space, eliminate effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

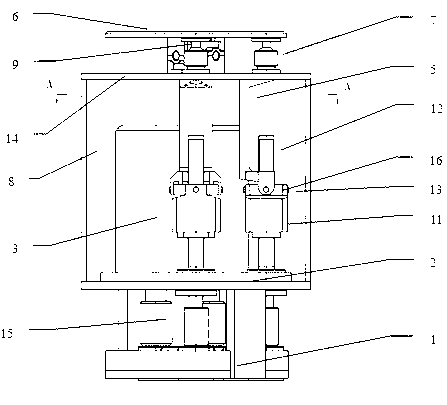

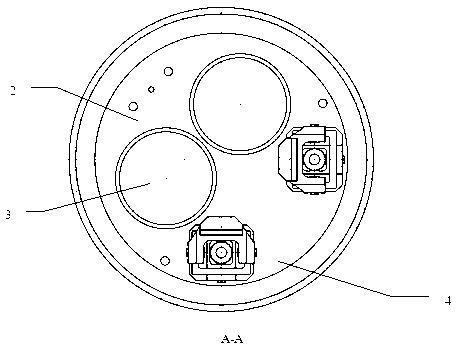

[0018] Embodiment 1 is the situation of two sets of parallel mechanisms 4, see figure 1 and figure 2 , the leveling device includes a gear transmission box 1, a static platform base 2, a driving motor 3, a parallel mechanism 4, a moving platform load connecting plate 6, a supporting outer wall 8, a moving platform fixing hinge 9, and a moving platform fixing plate 14.

[0019] see figure 1 and Figure 4 , the static platform base 2 is the assembly reference of all main parts of the whole stabilizing device, the gear transmission box 1, the drive motor 3 and the parallel mechanism 4 are all fixed here. The parallel mechanism 4 is perpendicular to the top of the static platform base 2, and the top of the parallel mechanism 4 is a load connection plate 6 of the moving platform, which is connected to each other by a ball joint 7. The driving motor 3 and the parallel mechanism 4 are on the same side of the static platform base 2, and the transmission of power between them is re...

Embodiment 2

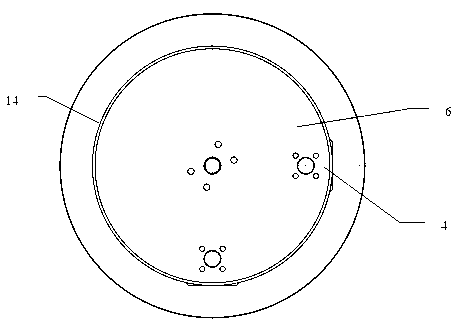

[0023] Embodiment 2 is the case of three sets of parallel mechanisms 4. The leveling device includes a gear transmission box 1, a static platform base 2, a driving motor 3, a parallel mechanism 4, a load connection plate 6 for a moving platform, and a supporting outer wall 8. The moving platform is fixed. Hinge 9, moving platform fixed plate 14 forms.

[0024] The static platform base 2 is the assembly reference of all main parts of the whole stabilizing device, and the gear transmission box 1, the drive motor 3 and the parallel mechanism 4 are all fixed here. The parallel mechanism 4 is perpendicular to the top of the static platform base 2, and the top of the parallel mechanism 4 is a load connection plate 6 of the moving platform, which is connected to each other by a ball joint 7. The driving motor 3 and the parallel mechanism 4 are on the same side of the static platform base 2, and the transmission of power between them is realized by the gear transmission box 1 installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com