Sheeting fixture

A technology for pressing sheet clamps and pressing plates, which is applied in the field of fixtures and fixtures, and can solve the problems of non-adjustable fixtures, displacement of sheet components, and inability to completely solve the deformation or displacement of sheet components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

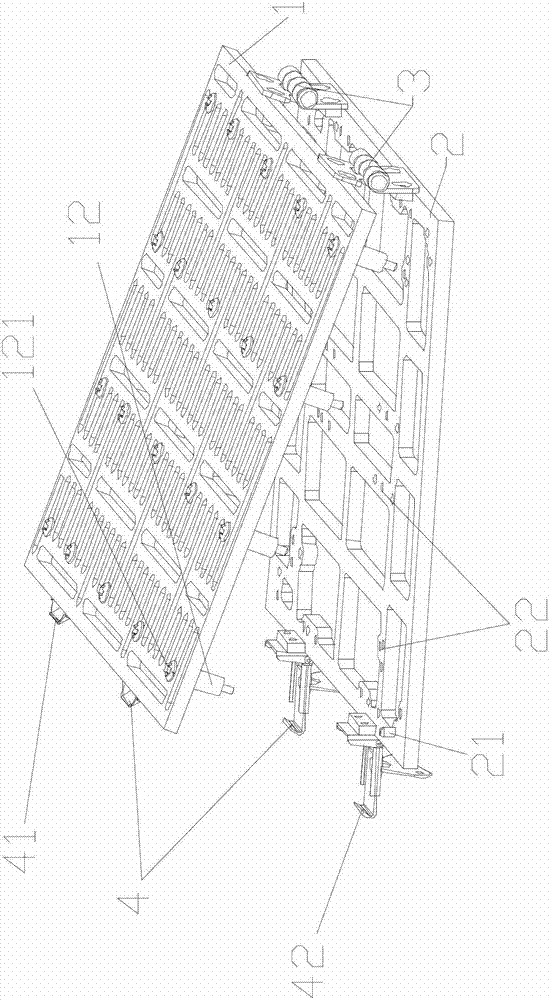

[0033] figure 1 It is a three-dimensional structural view of the best embodiment of the tablet pressing fixture of the present invention, which includes a pressing plate 1 , a bottom plate 2 , a pair of hinges 3 and a pair of buckles 4 . The pressing plate 1 and the base plate 2 are matched up and down, and are pivotally connected by a pair of hinges 3 on their same side, so that the pressing plate 1 can be opened around the hinges 3 at a certain angle; They are provided with a pair of buckles 4 relative to the other side where the hinge 3 is installed. The buckles 4 include an upper tenon part 41 and a lower tenon part 42 that can be mortized and jointed with each other. The lower tenon part 42 of the hasp 4 is arranged on the The edge of the bottom plate 2, the upper tenon part 41 is arranged on the corresponding position of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com